Abstract

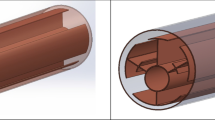

The design of thermal conductivity enhancers (TCE) is quite critical to overcoming the disadvantage of the poor thermal conductivity of phase change materials (PCM). The main contribution of this study is firstly to discuss how to actively enhance natural convection of the melted PCM in cellular structure by the fin formed in the structure under the condition of the same metal mass, apart from simultaneously improving heat conduction, which can boost the heat transfer performance. Also, a tailored hybrid fin-lattice structure (HFS) as TCE is designed and fabricated by additive manufacturing (AM). A two-equation numerical method is applied to study the heat transfer of the PCM, and its feasibility is validated with the experimental data. The numerical results indicate that enhanced natural convection and improved heat conduction can be obtained simultaneously when a well-designed fin is embedded into a lattice structure. The enhanced natural convection results in the improved melting rate and the decreased wall temperature; e.g., the complete melting time and the wall temperature are reduced by 11.6% and 19.7%, respectively, because of the fin for metal aluminum. Moreover, the parameters of HFS including the porosity, pore density, and fin dimension have a great impact on the heat transfer. The enhancement effect of the fin for HFS on the melting rate of the PCM increases as the thermal conductivity of the base material decreases. For example, when the fin is introduced into the lattice structure, the complete melting time is reduced by 24.1% for metal titanium. In summary, this study enables us to obtain a good understanding of the mechanism of the heat transfer and provides necessary experimental data for the structural design of HFS fabricated by AM.

Similar content being viewed by others

Abbreviations

- a sf :

-

interfacial surface area/m−1

- C pf :

-

specific heat capacity of PCM/kJ·(kg·K)−1

- C ps :

-

specific heat capacity of metal/kJ·(kg·K)−1

- d 1 :

-

the rod diameter of the pyramidal unit cell of lattice structure/mm

- E :

-

thermal energy/J

- f 1 :

-

the content of liquid PCM in semi-melted state

- H :

-

the height of the sample/mm

- h :

-

the height of fin/mm

- h sf :

-

interfacial heat transfer coefficient/W·(m2·K)−1

- k e :

-

effective thermal conductivity/W·(m·K)−1

- k se :

-

effective thermal conductivity of cellular structure/W·(m·K)−1

- k fe :

-

effective thermal conductivity of fluid/W·(m·K)−1

- k s :

-

thermal conductivity of solid/W·(m·K)−1

- k f :

-

thermal conductivity of fluid/W·(m·K)−1

- L :

-

the length of the sample/mm

- \(\dot L\) :

-

latent heat of the phase change material/kJ·kg−1

- ΔL :

-

the length of the epitaxial part of the substrates/mm

- l 1 :

-

the rod length of the pyramidal unit cell of lattice structure/mm

- m :

-

mass/kg

- q :

-

heat flux/W·m−2

- S :

-

the additional term

- T :

-

temperature/K

- T m1 :

-

the lower limit of melting point/K

- T m2 :

-

the upper limit of melting point/K

- T 0 :

-

initial temperature/K

- t 1 :

-

the thickness of fin/mm

- u, v, w :

-

velocity in x, y and z directions/m·s−1

- W :

-

the width of the sample/mm

- x, y, z :

-

cartesian coordinates

- β :

-

thermal expansion coefficient/K−1

- ρ :

-

density of materials/kg·m−3

- ε :

-

porosity of the metal cellular structure

- θ :

-

the angle of the rods of the pyramidal unit cell of lattice structure/(°)

- μ f :

-

dynamic viscosity of phase change material in liquid phase/Pa·s

- f :

-

fluid

- s :

-

solid

References

Tauseef-ur-R., Ali H.M., Janjua M.M., et al., A critical review on heat transfer augmentation of phase change materials embedded with porous materials/foams. International Journal of Heat and Mass Transfer, 2019, 135: 649–673.

Zhao C., Opolot M., Liu M., et al., Simulations of melting performance enhancement for a PCM embedded in metal periodic structures. International Journal of Heat and Mass Transfer, 2021, 168: 120853.

Mao Q., Chen H., Yang Y., Energy storage performance of a PCM in the solar storage tank. Journal of Thermal Science, 2019, 28(2): 195–203.

Ling Z., Zhang Z., Shi G., et al., Review on thermal management systems using phase change materials for electronic components, Li-ion batteries and photovoltaic modules. Renewable and Sustainable Energy Reviews, 2014, 31: 427–438.

Cui Y., Liu C., Hu S., et al., The experimental exploration of carbon nanofiber and carbon nanotube additives on thermal behavior of phase change materials. Solar Energy Materials and Solar Cells, 2011, 95(4): 1208–1212.

Siahpush A., O’brien J., Crepeau J., Phase change heat transfer enhancement using copper porous foam. Journal of Heat Transfer, 2008, 130(8): 082301.

Ramakrishnan S., Wang X., Sanjayan J., Effects of various carbon additives on the thermal storage performance of form-stable PCM integrated cementitious composites. Applied Thermal Engineering, 2019, 148: 491–501.

Ji C., Qin Z., Dubey S., et al., Simulation on PCM melting enhancement with double-fin length arrangements in a rectangular enclosure induced by natural convection. International Journal of Heat and Mass Transfer, 2018, 127: 255–265.

Kamkari B., Groulx D., Experimental investigation of melting behaviour of phase change material in finned rectangular enclosures under different inclination angles. Experimental Thermal and Fluid Science, 2018, 97: 94–108.

Ye W.-B., Guo H.-J., Huang S.-M., et al., Research on melting and solidification processes for enhanced double tubes with constant wall temperature/wall heat flux. Heat Transfer-Asian Research, 2018, 47(3): 583–599.

Ibrahim N.I., Al-Sulaiman F.A., Rahman S., et al., Heat transfer enhancement of phase change materials for thermal energy storage applications: A critical review. Renewable and Sustainable Energy Reviews, 2017, 74: 26–50.

Fan L., Khodadadi J.M., Thermal conductivity enhancement of phase change materials for thermal energy storage: A review. Renewable and Sustainable Energy Reviews, 2011, 15(1): 24–46.

Liu L., Su D., Tang Y., et al., Thermal conductivity enhancement of phase change materials for thermal energy storage: A review. Renewable and Sustainable Energy Reviews, 2016, 62: 305–317.

Yang X., Bai Q., Guo Z., et al., Comparison of direct numerical simulation with volume-averaged method on composite phase change materials for thermal energy storage. Applied Energy, 2018, 229: 700–714.

Deng S., Nie C., Wei G., et al., Improving the melting performance of a horizontal shell-tube latent-heat thermal energy storage unit using local enhanced finned tube. Energy and Buildings, 2019, 183: 161–173.

Saha S.K., Dutta P., Role of melt convection on optimization of PCM-based heat sink under cyclic heat load. Heat Transfer Engineering, 2013, 34(11–12): 950–958.

Nayak K.C., Saha S.K., Srinivasan K., et al., A numerical model for heat sinks with phase change materials and thermal conductivity enhancers. International Journal of Heat and Mass Transfer, 2006, 49(11–12): 1833–1844.

Feng S., Shi M., Li Y., et al., Pore-scale and volume-averaged numerical simulations of melting phase change heat transfer in finned metal foam. International Journal of Heat and Mass Transfer, 2015, 90: 838–847.

Guo J., Liu Z., Du Z., et al., Effect of fin-metal foam structure on thermal energy storage: An experimental study. Renewable Energy, 2021, 172: 57–70.

Yang X., Niu Z., Guo J., et al., Role of pin fin-metal foam composite structure in improving solidification: Performance evaluation. International Communications in Heat and Mass Transfer, 2020, 117: 104775.

Zhu F., Zhang C., Gong X., Numerical analysis on the energy storage efficiency of phase change material embedded in finned metal foam with graded porosity. Applied Thermal Engineering, 2017, 123: 256–265.

Ghahremannezhad A., Xu H., Salimpour M.R., et al., Thermal performance analysis of phase change materials (PCMs) embedded in gradient porous metal foams. Applied Thermal Engineering, 2020, 179: 115731.

Yang J., Yang L., Xu C., et al., Numerical analysis on thermal behavior of solid–liquid phase change within copper foam with varying porosity. International Journal of Heat and Mass Transfer, 2015, 84: 1008–1018.

Yang X., Wang W., Yang C., et al., Solidification of fluid saturated in open-cell metallic foams with graded morphologies. International Journal of Heat and Mass Transfer, 2016, 98: 60–69.

Zhang Y., Ma G., Wang J., et al., Numerical and experimental study of phase-change temperature controller containing graded cellular material fabricated by additive manufacturing. Applied Thermal Engineering, 2019, 150: 1297–1305.

Zhang Z., He X., Three-dimensional numerical study on solid-liquid phase change within open-celled aluminum foam with porosity gradient. Applied Thermal Engineering, 2017, 113: 298–308.

Zhao C. Y., Lu W., Tian Y., Heat transfer enhancement for thermal energy storage using metal foams embedded within phase change materials (PCMs). Solar Energy, 2010, 84(8): 1402–1412.

Chen J., Yang D., Jiang J., et al., Research progress of phase change materials (PCMs) embedded with metal foam (a review). Procedia Materials Science, 2014, 4: 389–394.

Swaminathan Gopalan K., Eswaran V., Numerical investigation of thermal performance of PCM based heat sink using structured porous media as thermal conductivity enhancers. International Journal of Thermal Sciences, 2016, 104: 266–280.

Hu X., Gong X., Experimental and numerical investigation on thermal performance enhancement of phase change material embedding porous metal structure with cubic cell. Applied Thermal Engineering, 2020, 175: 115337.

Hu X., Gong X., Pore-scale numerical simulation of the thermal performance for phase change material embedded in metal foam with cubic periodic cell structure. Applied Thermal Engineering, 2019, 151: 231–239.

Li W.Q., Qu Z.G., He Y.L., et al., Experimental and numerical studies on melting phase change heat transfer in open-cell metallic foams filled with paraffin. Applied Thermal Engineering, 2012, 37: 1–9.

Zhu F., Zhang C., Gong X., Numerical analysis and comparison of the thermal performance enhancement methods for metal foam/phase change material composite. Applied Thermal Engineering, 2016, 109: 373–383.

Luo Y., Li Q., Liu S., Topology optimization of shell–infill structures using an erosion-based interface identification method. Computer Methods in Applied Mechanics and Engineering, 2019, 355: 94–112.

Luo Y., Chen W., Liu S., et al., A discrete-continuous parameterization (DCP) for concurrent optimization of structural topologies and continuous material orientations. Composite Structures, 2020, 236: 111900.

Luo Y., Sigmund O., Li Q., et al., Additive manufacturing oriented topology optimization of structures with self-supported enclosed voids. Computer Methods in Applied Mechanics and Engineering, 2020, 372: 113385.

Nagesha B.K., Dhinakaran V., Varsha Shree M., et al., Review on characterization and impacts of the lattice structure in additive manufacturing. Materials Today: Proceedings, 2020, 21: 916–919.

Hu X., Gong X., Experimental study on the thermal response of PCM-based heat sink using structured porous material fabricated by 3D printing. Case Studies in Thermal Engineering, 2021, 24: 100844.

Tian Y., Zhao C.Y., A numerical investigation of heat transfer in phase change materials (PCMs) embedded in porous metals. Energy, 2011, 36(9): 5539–5546.

Krishnan S., Murthy J.Y., Garimella S.V., A two-temperature model for solid-liquid phase change in metal foams. Journal of Heat Transfer, 2005, 127(9): 995–1004.

Boomsma K.P.D., On the effective thermal conductivity of a three-dimensionally structured fluid-saturated metal foam. International Journal of Heat and Mass Transfer, 2001, 44(4)): 827–836.

Bhattacharya A C.V.V., Mahajan R.L., Thermophysical properties of high porosity metal foams. International journal of heat and mass transfer, 2002, 45(5): 1017–1031.

Žukauskas A., Heat transfer from tubes in crossflow. 1972, 8: 93–160.

Calmidi V.V., Mahajan R.L., Forced convection in high porosity metal foams. Journal of Heat Transfer, 2000, 122(3): 557–565.

Yang X.H., Kuang J.J., Lu T.J., et al., A simplistic analytical unit cell based model for the effective thermal conductivity of high porosity open-cell metal foams. Journal of Physics D: Applied Physics, 2013, 46(25): 255302.

Yang X.H., Bai J.X., Yan H.B., et al., An analytical unit cell model for the effective thermal conductivity of high porosity open-cell metal foams. Transport in Porous Media, 2014, 102(3): 403–426.

Yang X., Lu T.J., Kim T., An analytical model for permeability of isotropic porous media. Physics Letters A, 2014, 378(30–31): 2308–2311.

Acknowledgements

The authors gratefully acknowledge the financial support to this work by the National Natural Science Foundation of China (Grant No. 11972105, U1808215 and 11821202), the 111 Project (B14013) and the Fundamental Research Funds for the Central Universities of China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Kong, D., Zhang, Y. & Liu, S. Enhanced Natural Convection for Accelerating Melting of Phase Change Material in Cellular Structure through Inserting Fin. J. Therm. Sci. 33, 548–563 (2024). https://doi.org/10.1007/s11630-023-1841-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-023-1841-8