Abstract

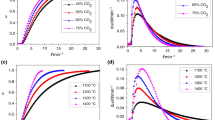

In order to mitigate the slagging risks of high-alkali coal (HAC) gasification while optimizing the operating temperatures for practical application, the experimental and calculational works were performed on the horizontal tubular furnace system and the FactSage 7.2 software, respectively. The slagging tendencies of three HACs were anticipated by applying different indexes of ash chemistry characteristics prior to experiments, but the determined results were found inconsistent. The relationship between Na retained ratio (RNa) and the ash fusion temperatures (AFTs) of gasification residues demonstrated that the AFTs of coal with high RNa are low, while AFTs of coal with low RNa are high. Nevertheless, when the residues contained a large number of calcium-containing silicates and aluminosilicates, the ATFs were reduced significantly even if its RNa stayed at a low level. Furthermore, the operating temperatures of the three coals (in order of Mulei coal, Shaerhu coal, and Tietou coal) were suggested to be controlled below 1150°C, 1100°C, and 950°C, respectively.

Similar content being viewed by others

Abbreviations

- A :

-

ash ratio/%

- AFTs:

-

ash fusion temperatures/°C

- C :

-

gasification residue ratio/%

- CFB:

-

circulating fluidized bed

- EDX:

-

energy dispersive X-ray spectrometer

- HAC:

-

high-alkali coal

- OVcoal :

-

value of sodium in raw coal/mg·g−1

- OVresidue :

-

value of sodium in gasification residues/mg·g−1

- SEM:

-

scanning electron microscopy

- R NA :

-

retention ratio of sodium/%

- R B/A :

-

alkali/acid ratio

- R F/C :

-

iron/calcium ratio

- R S/A :

-

silica/alumina ratio

- ST:

-

softening temperature/°C

- XRD:

-

X-ray diffraction

- XRF:

-

X-ray fluorescence

References

Song W.J., Song G.L., Qi X.B., Speciation and distribution of sodium during Zhundong coal gasification in a circulating fluidized bed. Energy & Fuels, 2017, 31(2): 1889–1895.

Song G.L., Qi X.B., Song W.J., Slagging behaviors of high alkali Zhundong coal during circulating fluidized bed gasification. Fuel, 2016, 186: 140–149.

Chen C.J., Hung C.I., Chen W.H., Numerical investigation on performance of coal gasification under various injection patterns in an entrained flow gasifier. Applied Energy, 2012, 100: 218–228.

Chen X.D., Kong L.X., Bai J., The key for sodium-rich coal utilization in entrained flow gasifier: The role of sodium on slag viscosity-temperature behavior at high temperatures. Applied Energy, 2017, 206: 1241–1249.

Zhu S.J., Zhu J.G., Lyu Q.G., NO emissions under pulverized char combustion in O2/CO2/H2O preheated by a circulating fluidized bed. Fuel, 2019, 252: 512–521.

Song W.J., Song G.L., Qi X.B., Transformation characteristics of sodium in Zhundong coal under circulating fluidized bed gasification. Fuel, 2016, 182: 660–667.

Namkung H., Xu L.H., Shin W.C., Study on deposition tendency of coal ash under various gasification environments through DTF. Fuel, 2014, 117: 1274–1280.

Wei X.F., Huang J.J., Liu T.F., Transformation of alkali metals during pyrolysis and gasification of a lignite. Energy & Fuels, 2008, 22(3): 1840–1844.

Li F.H., Ma X.W., Xu M.L., Regulation of ash-fusion behaviors for high ash-fusion-temperature coal by coal blending. Fuel Processing Technology, 2017, 166: 131–139.

Cheng X.L., Wang Y.G., Lin X.C., Effects of SiO2 Al2O3-CaO/FeO low-temperature eutectics on slagging characteristics of coal ash. Energy & Fuels, 2017, 31(7): 6748–6757.

Zhang Y.K., Ren Q.Q., Deng H.X., Ash fusion properties and mineral transformation behavior of gasified semichar at high temperature under oxidizing atmosphere. Energy & Fuels, 2017, 31(12): 14228–14236.

Shi W.J., Kong L.X., Bai J., Effect of CaO/Fe2O3 on fusion behaviors of coal ash at high temperatures. Fuel Processing Technology, 2018, 181: 18–24.

Niu Y.Q., Tan H.Z., Hui S.E., Ash-related issues during biomass combustion: Alkali-induced slagging, silicate melt-induced slagging (ash fusion), agglomeration, corrosion, ash utilization, and related countermeasures. Progress in Energy and Combustion Science, 2016, 52: 1–61.

Jing N.J., Wang Q.H., Cheng L.M., Effect of temperature and pressure on the mineralogical and fusion characteristics of Jincheng coal ash in simulated combustion and gasification environments. Fuel, 2013, 104: 647–655.

Qiu J.R., Li F., Zheng Y., The influences of mineral behaviour on blended coal ash fusion characteristics. Fuel, 1999, 78(8): 963–969.

Runsheng Y., Li X.H., Zuo Y.F., Effect of sodium based flux on the ash melting characteristics temperature of Lingshi coal. Journal of China Coal Society, 2011, 36(6): 1027–1031.

Van Dyk J.C., Keyser M.J., Influence of discard mineral matter on slag-liquid formation and ash melting properties of coal — A FACTSAGE (TM) simulation study. Fuel, 2014, 116: 834–840.

Wang Y., Xiang Y., Wang D.X., Effect of sodium oxides in ash composition on ash fusibility. Energy & Fuels, 2016, 30(2): 1437–1444.

Li H.X., Ninomiya Y., Dong Z.B., Application of the FactSage to predict the ash melting behavior in reducing conditions. Chinese Journal of Chemical Engineering, 2006, 14(6): 784–789.

Dai B.Q., Wu X., Inhibition of lignite ash slagging and fouling upon the use of a silica-based additive in an industrial pulverised coal-fired boiler. Part 1. Changes on the properties of ash deposits along the furnace. Fuel, 2015, 139: 720–732.

Fan Y. Q., Lyu Q.G., Zhu Z.P., The impact of additives upon the slagging and fouling during Zhundong coal gasification. Journal of the Energy Institute, 2020, 93(4): 1651–1665.

Gong Z.Q., Wang Z.T., Wang Z.B., Study on migration characteristics of heavy metals during oil sludge incineration. Petroleum Science and Technology, 2018, 36(6): 469–474.

Song W.J., Sun Y.M., Wu Y.Q., et al., Measurement and simulation of flow properties of coal ash slag in coal gasification. Aiche Journal, 2011, 57(3): 801–818.

Jing N.J., Wang Q.H., Luo Z.Y., Effect of different reaction atmospheres on the sintering temperature of Jincheng coal ash under pressurized conditions. Fuel, 2011, 90(8): 2645–2651.

Fan J.Y., Research on Zhundong coal’s slagging characteristic and its ash fusiblity of blending coal. Zhejiang University, Zhejiang, China, 2014.

Zhang X.Y., Zhang H.X., Na Y.J., Migration characteristics and morphological changes of sodium during ashing process of Zhundong coal. Clean Coal Technology, 2015, (02): 45–50, 55. (in Chinese)

Zhang X.Y., Zhang H.X., Na Y.J., Transformation of sodium during the ashing of Zhundong coal. Elsevier Science Bv, Amsterdam 2015, pp. 305–314.

Qi X.B., Song G.L., Song W.J., Effect of bed materials on slagging and fouling during Zhundong coal gasification. Energy Exploration & Exploitation, 2017, 35(5): 558–578.

Teixeira P., Lopes H., Gulyurtlu I., Evaluation of slagging and fouling tendency during biomass co-firing with coal in a fluidized bed. Biomass & Bioenergy, 2012, 39: 192–203.

Fuller A., Maier J., Karampinis E., Fly ash formation and characteristics from (co-)combustion of an herbaceous biomass and a greek lignite (low-rank coal) in a pulverized fuel pilot-scale test facility. Energies, 2018, 11(6): 1581.

Zhang Z., Zhao D.S., Wang S.F., Study on slagging characteristics of burning coal. Coal and Chemical Industry 2017, (03): 28–30.

Wei B., Wang X.B., Tan H.Z., Effect of silicon-aluminum additives on ash fusion and ash mineral conversion of Xinjiang high-sodium coal. Fuel, 2016, 181: 1224–1229.

Li L.N., Ren Q.Q., Li S.Y., Behavior of alkali metal during combustion of wheat straw with phosphorus-rich additives. Proceedings of the Chinese Society of Electrical Engineering, 2013, (26): 41–47, 41. (in Chinese)

Li W.Q., Wang L.Y., Qiao Y., Effect of atmosphere on the release behavior of alkali and alkaline earth metals during coal oxy-fuel combustion. Fuel, 2015, 139: 164–170.

Song W.J., Tang L.H., Zhu X.D., Effect of coal ash composition on ash fusion temperatures. Energy & Fuels, 2010, 24(1): 182–189.

Wu X.J., Zhang X., Yan K., Ash deposition and slagging behavior of Chinese Xinjiang high-alkali coal in 3 MWth pilot-scale combustion test. Fuel, 2016, 181: 1191–1202.

Wu X.J., Zhang X., Dai B.Q., Ash deposition behaviours upon the combustion of low-rank coal blends in a 3 MWth pilot-scale pulverised coal-fired furnace. Fuel Processing Technology, 2016, 152: 176–182.

Qi X.B., Study on slagging and fouling characteristics of high-alkali low-rank coal during thermochemical conversion process. Beijing: University of Chinese Academy of Sciences, 2018.

Acknowledgment

This work was financially supported by Beijing Municipal Science and Technology Commission (No. Z181100005118006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, Y., Zhang, H., Zhu, Z. et al. Slagging Characteristics and Optimization of Operating Temperature on High-Alkali Coal Gasification. J. Therm. Sci. 30, 644–655 (2021). https://doi.org/10.1007/s11630-021-1410-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-021-1410-y