Abstract

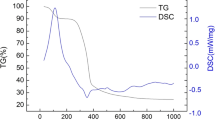

In order to effectively investigate the variation of gas production characteristics of biomass under normal-speed pyrolysis conditions, the gas production rate, gas production component yield and gas production calorific value of pine sawdust with adding Na2CO3, CaO and Fe2O3 were systematically analyzed. In the experiment, an improved tube furnace was used to research the pyrolysis process with the temperature from 350°C to 750°C. The results indicate that the gas yield rises with the increase of temperature without additives, reaching 19.59% at 750°C. The liquid yield reaches 59.38% at 450°C and then the yield change is small. CaO increases the calorific value of the pyrolysis product gas due to the adsorption of CO2. Na2CO3 is fused with inorganic substances in the biomass to form a char skeleton structure. The effect of Fe2O3 on H2 is more obvious at higher temperature. Na2CO3 has the most obvious effect on the pyrolysis of pine sawdust among the discussed additives, which effectively promotes the production of H2.

Similar content being viewed by others

References

Bai Z., Liu Q., Gong L., et al., Investigation of a solar-biomass gasification system with the production of methanol and electricity: Thermodynamic, economic and off-design operation. Applied Energy, 2019, 243: 91–101.

Backreedy R.I., Fletcher L.M., Jones J.M., et al., Co-firing pulverised coal and biomass: a modeling approach. Proceedings of the Combustion Institute, 2005, 30: 2955–2964.

Ma L., Jones J.M., Pourkashanian M., et al., Modelling the combustion of pulverized biomass in an industrial combustion test furnace. Fuel, 2007, 86: 1959–1965.

Somers K.P., Curran H.J., Burke U., et al., The importance of endothermic pyrolysis reactions in the understanding of diesel spray combustion. Fuel, 2018, 224: 302–310.

Gauthier G., Melkior T., Salvador S., et al., Pyrolysis of thick biomass particles: experimental and kinetic modelling. Chemical Engineering Transactions, 2018, 32: 601–606.

Mohammed M., Salmiaton A., Azlina W., et al., Preparation and characterization of malaysian dolomites as a tar cracking catalyst in biomass gasification process. Journal of Energy, 2017, 15: 325–351.

Bartocci P., Anca-Couce A., Slopiecka K., et al., Pyrolysis of pellets made with biomass and glycerol: Kinetic analysis and evolved gas analysis. Biomass & Bioenergy, 2017, 97: 11–19.

Gaston K.R., Jarvis M.W., Pepiot P., et al., Biomass pyrolysis and gasification of varying particle sizes in a fluidized-bed reactor. Energy & Fuels, 2011, 25: 3747–3757.

Bai Z., Liu Q., Lei J., et al., A polygeneration system for the methanol production and the power generation with the solar-biomass thermal gasification. Energy Conversion and Management, 2015, 102: 190–201.

Williams P.T., Nugranad N., et al., Comparison of products from the pyrolysis and catalytic pyrolysis of rice husks. Energy, 2000, 25: 493–513.

Richardson Y., Motuzas J., Julbe A., et al., Catalytic investigation of in situ generated Ni metal nanoparticles for tar conversion during biomass pyrolysis. Journal of Physical Chemistry C, 2018, 117: 23812–23831.

Elkins T.W., Roberts S.J., Hagelin-Weaver H.E., et al., Effects of alkali and alkaline-earth metal dopants on magnesium oxide supported rare-earth oxide catalysts in the oxidative coupling of methane. Applied Catalysis A General, 2016, 528: 175–190.

Guan G., Kaewpanha M., Hao X., et al., Catalytic steam reforming of biomass tar: prospects and challenges. Renewable & Sustainable Energy Reviews, 2016, 58: 450–461.

Demirbas A., Yields of hydrogen-rich gaseous products via pyrolysis from selected biomass samples. Fuel, 2001, 80: 1885–1891.

Chen G., Andries J., Spliethoff H., Catalytic pyrolysis of biomass for hydrogen rich fuel gas production. Energy Conversion & Management, 2003, 44: 2289–2296.

Deng W., Yu W., Su Y., Effects of CaO, ZnCl2 and water vapor on hydrogen rich gas formation during microwave pyrolysis of sewage sludge. Journal of Donghua University, 2014, 40: 624–632.

Zhang T., Wang W., Catalytic pyrolysis of rice husks for syngas production over Fe-based catalyst in a fixed-bed reactor. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2016, 38: 2190–2196.

Han J., Kim H., The reduction and control technology of tar during biomass gasification/pyrolysis: An overview. Renewable & Sustainable Energy Reviews, 2008, 12: 397–416.

Sun Y., Jiang J., Study on biomass pyrolysis and gasification. Chemistry & Industry of Forest Products, 2007, 27: 15–20.

Jiang J., Jin C., Zhang J., et al., Study on industrial applied technology for biomass catalytic gasification. Chemistry & Industry of Forest Products, 2001, 21: 21–26.

Jiang J., Ying H., Dai W., et al., Study on the industry technology of catalytic gasification of biomass with a fluidizated bed. Acta Energiae Solaris Sinica, 2004, 25: 678–684.

Wang T., Chang J., Lv P., et al., Novel catalyst for cracking of biomass tar. Energy & Fuels, 2005, 19: 22–27.

Wang S., Luo Z., Pyrolysis of biomass components, Beijing, 2013.

Fisher T., Hajaligol M., Waymack B., et al., Pyrolysis behavior and kinetics of biomass derived materials. Journal of Analytical and Applied Pyrolysis, 2002, 62: 331–349.

Avni E., Coughlin R.W., Solomon P.R., et al., Mathemayical-modeling of lignin pyrolysis. Fuel, 1985, 64: 1495–1501.

Yun Y., Liu D., Wu H., Formation and characteristics of reaction intermediates from the fast pyrolysis of NaCl-and MgCl2-loaded celluloses. Energy & Fuels, 2013, 28: 245–253.

Fu Q., Argyropoulos D.S., Tilotta D.C., et al., Understanding the pyrolysis of CCA-treated wood: Part I. Effect of metal ions. Journal of Analytical & Applied Pyrolysis, 2008, 81: 60–64.

Richards G.N., Zheng G., Influence of metal ions and of salts on products from pyrolysis of wood: Applications to thermochemical processing of newsprint and biomass. Journal of Analytical & Applied Pyrolysis, 1991, 21: 133–146.

Wei L., Yang H., Li B., et al., Absorption-enhanced steam gasification of biomass for hydrogen production: Effect of calcium oxide addition on steam gasification of pyrolytic volatiles. International Journal of Hydrogen Energy, 2014, 39: 15416–15423.

Zhang B., Dong J., Wang W., Research on pyrolysis characteristics and kinetics of peanut shell over Fe2O3 catalyst. Speciality Petrochemicals, 2017, 34: 77–82.

Dong L., Asadullah M., Zhang S., An advanced biomass gasification technology with integrated catalytic hot gas cleaning: Part I. Technology and initial experimental results in a lab-scale facility. Fuel, 2013, 108: 409–416.

Virginie M., Courson C., Kiennemann A., Toluene steam reforming as tar model molecule produced during biomass gasification with an iron/olivine catalyst. Comptes Rendus Chimie, 2010, 13: 1319–1325.

Tamhankar S.S., Tsuchiya K., Riggs J.B., Catalytic cracking of benzene on iron oxide-silica: catalyst activity and reaction mechanism. Applied Catalysis, 1985, 16: 103–121.

Swierczynski D., Courson C., Bedel L., Oxidation reduction behavior of iron-bearing olivines (FexMg1-x)2SiO4 used as catalysts for biomass gasification. Cheminform, 2006, 18: 897–905.

Nordgreen T., Liliedahl T., Sjostrom K., Metallic iron as a tar breakdown catalyst related to atmospheric, fluidised bed gasification of biomass. Fuel, 2006, 85: 689–694.

Dong L., Asadullah M., Zhang S., An advanced biomass gasification technology with integrated catalytic hot gas cleaning. Fuel, 2013, 108: 409–416.

Guo D., Wu S., Liu B., Catalytic effects of NaOH and Na2CO3 additives on alkali lignin pyrolysis and gasification. Applied Energy, 2012, 95: 22–30.

Ma C., Xiao B., Chen Y., Experimental research on biomass gasification for hydrogen rich gas production. Journal of Combustion Science & Technology, 2007, 13: 461–467.

Acknowledgements

The authors are grateful for the financial support by Inner Mongolia Autonomous Region Natural Science Fund (2018MS05046) and the National Natural Science Foundation of China (No. 51706111).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, D., Jin, G., Pang, Y. et al. Gas Characteristics of Pine Sawdust Catalyzed Pyrolysis by Additives. J. Therm. Sci. 30, 333–342 (2021). https://doi.org/10.1007/s11630-020-1244-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-020-1244-z