Abstract

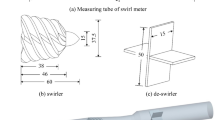

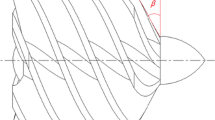

Flow measurement is important in the fluid process and transmission system. For the need of accuracy measurement of fluid, stable flow is acquired. However, the elbows and devices as valves and rotary machines may produce swirling flow in the natural gas pipeline networks system and many other industry fields. In order to reveal the influence of upstream swirling flow on internal flow fields and the metrological characteristics, numerical simulations are carried out on the swirl meter. Using RNG k-ε turbulent model and SIMPLE algorithm, the flow field is numerically simulated under swirling flows generated from co-swirl and counter-swirl flow. Simulation results show fluctuation is enhanced or weakened depending on the rotating direction of swirling flow. A counter- swirl flow increases the entropy production rate at the inlet and outlet of the swirler, the junction region between throat and divergent section, and then the pressure loss is increased. The vortex precession dominates the static pressure distributions on the solid walls and in the channel, especially at the end region of the throat.

Similar content being viewed by others

References

Miller, R.W., 1989. Flow Measurement Engineering Handbook. 2nd ed. New York: McGraw-Hill.

Wang, C., Wang, Z., Zhang, Baozhu, Sun. H., 2012. Flow measurement technique handbook. Chemical Industry Press.

Dijstelbergen, H.H., 1970. The performance of a swirl flowmeter. Journal of Physics. E: Scientific Instruments. 11(3), 886–888.

Heinrichs, K., 1991. Flow measurement by a new pushpull swirlmeter. Sensors and Actuators A: Physical. 25–27, 809–813.

Cascetta, F., Scalabrini, G., 1999. Field test of a swirlmeter for gas flow measurement. Flow Measurement and Instrumentation. 10, 183–188.

Chao, T., Hao, W., Can, W., Feng, D., 2013. Experimental and numerical design of a long-waist cone flow meter. Sensors and Actuators A: Physical. 199, 9–17.

Liu, W., Xu, Y., Zhang, T., Qi, F., 2015. Experimental optimization for dual support structures cone flow meters based on cone wake flow field characteristics. Sensors and Actuators A: Physical. 232, 115–131.

Clarke, D.W., Ghaoud, T., 2003. A dual phase-locked loop for vortex flow metering. Flow Measurement and Instrumentation. 14, 1–11.

Sondkar, S., Abhyankar, H., Fernandes, N., 2014. Computationally lean algorithm of novel optimal FIR adaptive filter for vortex signal extraction. Flow Measurement and Instrumentation. 35, 28–38.

Venugopal, A., Agrawal, A., Prabhu, S.V., 2014. Performance evaluation of piezoelectric and differential pressure sensor for vortex flowmeters. Flow Measurement and Instrumentation. 50, 10–18.

Campos, S.R.V., Baliño, J.L., Slobodcicov, I., Filho, D.F., Paz, E.F. 2014. Orifice plate meter field performance: Formulation and validation in multiphase flow conditions. Experimental Thermal and Fluid Science. 58, 93–104.

He, D., Bai, B., 2012. Numerical investigation of wet gas flow in Venturi meter. Flow Measurement and Instrumentation. 28, 1–6.

Shaaban, S., 2014. Optimization of orifice meter’s energy consumption. Chemical Engineering Research and Design. 92, 1005–1015.

Singh, V.K., Tharakan, T.J., 2015. Numerical simulations for multi-hole orifice flowmeter. Flow Measurement and Instrumentation. 45, 375–383.

Fu, X., Yang, H., 2001. Study on mechanism of hydrodynamic oscillation in vortex precession meter using large eddy simulation. Chinese Journal of Mechanical Engineering. 14(1), 9–11.

Ghaoud, T., Clarke, D.W., 2002. Modelling and tracking a vortex flow-meter signal. Flow Measurement and Instrumentation. 13, 103–117.

Perumal, K., Michael W.M.B., 2011. A CFD study of low pressure wet gas metering using slotted orifice meters. Flow Measurement and Instrumentation. 22, 33–42.

Xu, Y., Gao, L., Zhao, Y., Wang, H., 2014. Wet gas over reading characteristics of a long-throat Venturi at high pressure based on CFD. Flow Measurement and Instrumentation. 40, 247–255.

Peng, J., Fu, X., Chen, Y., 2008. Response of a swirlmeter to oscillatory flow. Flow Measurement and Instrumentation, 19, 107–115.

Singh, R.K., Singh, S.N., Seshadri, V., 2010. CFD prediction of the effects of the upstream elbow fittings on the performance of cone flowmeters. Flow Measurement and Instrumentation. 21, 88–97.

Takano, T., Ikarashi, Y., Uchiyama, K., Yamagata, T., Fujisawa, N., 2016. Influence of swirling flow on mass and momentum transfer downstream of a pipe with elbow and orifice. International Journal of Heat and Mass Transfer. 92, 394–402.

Fujisawa, N., Kanatani, N., Yamagata, T., Takano, T., 2015. Mechanism of non-axisymmetric pipe-wall thinning in pipeline with elbow and orifice under influence of swirling flow, Nuclear Engineering and Design. 285, 126–133.

Chen, D., Cui, B., Zhu, Z., 2016. Research on Internal Flow and Performance of Swirlmeter with Different Swirler Cone Angle. Measurement & Control. 49(4), 136–142.

Chen, D., Cui, B., Zhu, Z., 2016. Internal Flow Characteristics and Aft-cone Angle on Performance of Swirlmeter. MAPAN-Journal of Metrology Society of India. 31(2), 107–113.

Li, D., Gong, R., Wang, H., et al., 2014. Entropy Production Analysis for Hump Characteristics of a Pump Turbine Model. Chinese Journal of Mechanical Engineering. 27(4), 1–10.

Acknowledgements

This work is supported by the National Natural Science Foundation of China (51579225).

Author information

Authors and Affiliations

Corresponding author

Additional information

This work is supported by the National Natural Science Foundation of China (51579225).

Rights and permissions

About this article

Cite this article

Chen, D., Cui, B. & Zhu, Z. Numerical simulation of the effect of upstream swirling flow on swirl meter performance. J. Therm. Sci. 27, 117–124 (2018). https://doi.org/10.1007/s11630-018-0992-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-018-0992-5