Abstract

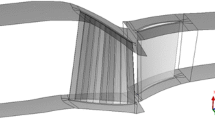

Aircraft engines deteriorate during continuous operation under the action of external factors including fouling, corrosion, and abrasion. The increased surface roughness of compressor passage walls limits airflow and leads to flow loss. However, the partial increase of roughness may also restrain flow separation and reduce flow loss. It is necessary to explore methods that will lower compressor deterioration, thereby improving the overall performance. The experimental research on the effects of surface roughness on highly loaded compressor cascade aerodynamics has been conducted in a low-speed linear cascade wind tunnel. The different levels of roughness are arranged on the suction surface and pressure surface, respectively. Ink-trace flow visualization has been used to measure the flow field on the walls of cascades, and a five-hole probe has been traversed across one pitch at the outlet. By comparing the total pressure loss coefficient, the distributions of the secondary-flow speed vector, and flow fields of various cases, the effects of surface roughness on the aerodynamics of a highly loaded compressor cascade are analyzed and discussed. The results show that adding surface roughness on the suction surface and pressure surface make the loss decrease in most cases. Increasing the surface roughness on the suction surface causes reduced flow speed near the blade, which helps to decrease mixing loss at the cascades outlet. Meanwhile, adding surface roughness on the suction surface restrains flow separation, leading to less flow loss. Various levels of surface roughness mostly weaken the flow turning capacity to various degrees, except in specific cases.

Similar content being viewed by others

References

Boynton, J. L., Tabibzadeh, R., and Hudson, S. T. Investigation of rotor blade roughness effects on turbine performance. Journal of Turbomachinery. 1993, 115: 614–620.

Kind, R. J., Serjak, P. J. and Abbott, M. W. P. Measurements and prediction of the effects of surface roughness on profile losses and deviation in a turbine cascade. Journal of Turbomachinery. 1998, 120: 20–27.

Bammert, K. and Stanstede, H. Measurements concerning the influence of surface roughness and profile changes on the performance of gas turbines. Journal of Engineering for Power. 1972, 94: 207–213.

Bammert, K. and Stanstede, H. Influences of manufacturing tolerances and surface roughness of blades on the performance of turbines. Journal of Engineering for Power. 1976, 98: 29–36.

Meher-Homji, C. B. Gas turbine axial compressor fouling — a unified treatment of its effects, detection and control. Int. J. Turbo and Jet Eng. 1992, 9(4): 99–111.

Meher-Homji, C. B., Chaker, M. and Bromley, A. F. The fouling of axial flow compressors — causes, effects, susceptibility and sensitivity. In Proceedings of ASME TURBO EXPO, 2009, GT-2009-59239, Vancouver, Canada.

Song, T. W., Sohn, J. L., Kim, T. S., Kim, J. H. and Ro, S. T. An improved analytic model to predict fouling phenomena in the axial compressor of gas turbine engines. In Proceedings of the International Gas Turbine Congress, 2003, IGTC2003Tokyo TS-095, Tokyo, Japan.

Morini, M., Pinelli M., Spina, P. R. and Venturini, M. Influence of blade deterioration on compressor and turbine performance. ASME J. Eng. Gas Turbines Power, 2010, 132: 032401.1–032401.11.

Kurz, R. and Brun, K. Fouling mechanisms in axial com pressor. Journal of Turbomachinery. 2012, 134(3):032401.1–032401.9.

Bammert, K. and Woelk, G. U. The influence of blading surface roughness on the aerodynamic behavior and characteristic of an axial compressor. ASME J. Eng. Gas Turbines Power. 1980, 102: 283–287.

Saxena, V. M., Mshrivastava, K. D., and Agrawal, P. K. Effect of surface roughness over the blade in compressor cascade. Journal of the Institution of Engineers (India): Mechanical Engineering Division. 1980, 61(1): 54–58.

Syverud, E. and Bakken, L. E. The impact of surface roughness on axial compressor performance deterioration. In Proceedings of ASME TURBO EXPO, 2006, GT-2006-90004, Barcelona, Spain.

Morini, M., Pinelli, M., Spina, P. R., and Venturini, M. Numerical analysis of the effects of non-uniform surface roughness on compressor stage performance. In Proceedings of ASME TURBO EXPO, 2010, GT2010-23291, Glasgow, UK.

Suder, K. L., Chima, R. V., Strazisar, A. J., and Roberts, W. B. The effect of adding roughness and thickness to a transonic axial compressor rotor. Journal of Turbomachinery. 1995, 117(4): 491–505.

Scott, J. N. Axial compressor deterioration by measuring air intake depression. National Research Roughness Council, Third symposium on gas turbine operations and maintenance, 1979, Ch13, Ottawa, Canada.

Syverud, E., Brekke, O. and Bakken, L. E. Axial compressor deterioration caused by saltwater ingestion. Journal of Turbomachinery. 2007, 129(1): 119–126.

Seung, C. B., In, C. J., Jeong, L. S. and Seung J. S. Influence of surface roughness on the performance of a compressor blade in a linear cascade — experiment and modeling. In Proceedings of ASME TURBO EXPO, 2009, GT2009-59703, Orlando, USA.

Seung, C. B., Hobson, G. V., Seung. J. S. and Millsps K. T. Effect of surface roughness location and Reynolds number on compressor cascade performance. In Proceedings of ASME TURBO EXPO, 2012, GT2012-22208, Copenhagen, Denmark.

Gbadebo, S. A., Hynes, T. P., and Cumpsty, N. A. Influence of surface roughness on three-dimensional separation in axial compressors. Journal of Turbomachinery. 2004, 126(4): 455–463.

Chen, S. W., Zhang, C., Shi, H., Wang, S. T. and Wang Z. Q. Study on the impact of fouling on axial compressor stage. In Proceedings of ASME TURBO EXPO, 2012, GT2012-68041, Copenhagen, De

Author information

Authors and Affiliations

Additional information

Financially supported from “National Natural Science Foundation of China” (Grant No. 51206035) and “the Foundation for Innovative Research Groups of the National Natural Science Foundation of China” (Grant No. 51121004).

Rights and permissions

About this article

Cite this article

Chen, Sw., Xu, H., Wang, St. et al. Experimental research of surface roughness effects on highly-loaded compressor cascade aerodynamics. J. Therm. Sci. 23, 307–314 (2014). https://doi.org/10.1007/s11630-014-0711-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-014-0711-9