Abstract

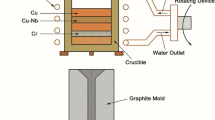

The effect of the gradient content of Co element on the solidification process of Cu-based alloy under deep under cooling conditions was explored. The non-equilibrium solidification structure of the under cooled alloy samples were analyzed. It is found that the rapidly solidified alloy has undergone twice grain refinement during the undercooling process. Characterization and significance of the maximum undercooling refinement structure of Cu60Ni35Co5 at T=253 K were analyzed. High-density defects were observed, such as dislocations, stacking faults networks, and twinning structures. The standard FCC diffraction pattern represents that it is still a single-phase structure. Based on the metallographic diagram, EBSD and TEM data analysis, it is illustrated that the occurrence of grain refinement under high undercooling is due to stress induced recrystallization. In addition, the laser cladding technology is used to coat Co-based alloy (Stellite12) coating on 304 stainless steel substrate; the microstructure of the coating cross-section was analyzed. It was found that the microstructure of the cross-section is presented as columnar crystals, planar crystals, and disordered growth direction, so that the coating has better hardness and wear resistance. By electrochemical corrosion of the substrate and coating, it can be seen that the Co and Cr elements present in the coating are more likely to form a dense passivation film, which improved the corrosion resistance of the coating.

Similar content being viewed by others

References

Zhang Duyao, Prasad Arvind, Bermingham Michael J, et al. Easton Mark A. Grain Refinement of Alloys in Fusion-Based Additive Manufacturing Processes[J]. Metallurgical and Materials Transactions A, 2020, 51(9): 4 341–4 359

Shang Zhao, Wei Xianping, Song Dazhuo, et al. Microstructure and Mechanical Properties of a New Nickel-based Single Crystal Super-alloy[J]. Journal of Materials Research and Technology, 2020, 9(5): 11 641–11 649

Yi I, Han S, Cho J. Development of the Plate Steels with Grain Refined Surface Layers[C]. In: Proceedings of the MS&T18, F, 2018

Yang Jun, Chen Mei Ling, Gao Hong. Microstructures and Mechanical Properties of Cast Aluminum Bronze Enhanced by Modified Nano-SiC Powders[J]. Advanced Materials Research, 2011, 335–336: 396–399

Walker JL. The Physical Chemistry of Process Metallurgy[M]. New York; Interscience Publishers, 1959

Leung KK, Chiu CP, Kui HW. Grain Refinement in Undercooled Nickel[J]. Scripta Metallurgica et Materialia, 1995, 32(10): 1 559–1 563

Di Schino A, Kenny JM. Grain Refinement Strengthening of a Micro-crystalline High Nitrogen Austenitic Stainless Steel[J]. Materials Letters, 2003, 57(12): 1 830–1 834

Lu SY, Li JF, Zhou YH. Grain Refinement in the Solidification of Undercooled Ni-Pd Alloys[J]. Journal of Crystal Growth, 2007, 309(1): 103–111

Zhang T, Liu F, Wang HF, et al. Grain Refinement in Highly Undercooled Solidification of Ni85Cu15 Alloy Melt: Direct Evidence for Recrystallization Mechanism[J]. Scripta Materialia, 2010, 63(1): 43–46

An Xuguang, Liu Ying, Ye Jinwen, et al. Grain Refining Performance of Al-Ti(C0.7, N0.3) Master Alloy and Its Effect on Mechanical Properties for Commercial Pure Aluminium[J]. Micro & Nano Letters, 2016, 11(6): 332–335

Wang Haifeng, Liu Feng, Yang Gencang. Experimental Study of Grain Refinement Mechanism in Undercooled Ni-15at%Cu Alloy [J]. Journal of Materials Research, 2011, 25(10): 1 963–1 974

Xu Xiaolong, Hou Hua, Zhao Yuhong, et al. Nonequilibrium Solidification, Grain Refinements, and Recrystallization of Deeply Undercooled Ni-20 At. Pct Cu Alloys: Effects of Remelting and Stress[J]. Metallurgical and Materials Transactions A, 2017, 48(10): 4 777–4 785

Li JF, Liu YC, Lu YL, et al. Structural Evolution of Undercooled Ni-Cu Alloys[J]. Journal of Crystal Growth, 1998, 192: 462–470

Schwarz M, Karma A, Eckler K, et al. Physical Mechanism of Grain Refinement in Solidification of Undercooled Melts [J]. Physical Review Letters, 1994, 73(10): 1 380–1 383

Kattamis TZ. Dendritic Peculiarities in Undercooled and Internally Chilled Fe-25 Pct Ni Alloy[J]. Metallurgical Transactions, 1971, 2(7): 2 000–2 003

Cochrane RF, Battersby SE, Mullis AM. The Mechanisms for Spontaneous Grain Refinement in Undercooled Cu-O and Cu-Sn Melts[J]. Materials Science and Engineering A, 2001, 304: 262–266

Liu Feng, Yang Gencang. Stress-induced Recrystallization Mechanism for Grain Refinement in Highly Undercooled Superalloy[J]. Journal of Crystal Growth, 2001, 231: 295–305

Dragnevski KI, Cochrane RF, Mullis AM. The Mechanism for Spontaneous Grain Refinement in Undercooled Pure Cu Melts[J]. Materials Science and Engineering A, 2004, 375: 479–484

Willnecker R, Herlach DM, Feuerbacher B. Grain Refinement Induced by a Critical Crystal Growth Velocity in Undercooled Melts[J]. Applied Physics Letters, 1990, 56(4): 324–326

Mullis AM, Cochrane RF. Grain Refinement and the Stability of Dendrites Growing into Undercooled Pure Metals and Alloys[J]. Journal of Applied Physics, 1997, 82(8): 3 783–3 790

Hunt JD, Jackson KA. Nucleation of Solid in an Undercooled Liquid by Cavitation[J]. Journal of Applied Physics, 1966, 37(1): 254–257

Boettinger WJ, Coriell SR, Trivedi R. Rapid Solidification Processing: Principles and Technologies IV[M]. Baton Rouge; Claitor’s Pulishing Division, 1988

Zhang P, Liu Z. Effect of Sequential Turning and Burnishing on the Surface Integrity of Cr-Ni-based Stainless Steel Formed by Laser Cladding Process[J]. Surface and Coatings Technology, 2015, 276: 327–335

Cheng Q, Shi H, Zhang P, et al. Microstructure, Oxidation Resistance and Mechanical Properties of Stellite 12 Composite Coating Doped with Submicron TiC/B4C by Laser Cladding[J]. Surface and Coatings Technology, 2020, 395: 125 810

Han Chenyang, SUN Yaoning, XU Yifei, et al. Wear and Electrochemical Corrosion Performance of Laser Clad Nickel-based Alloys[J]. Surface Technology, 2021, 50(11): 103–110

Jiang Huiling. Preparation of FeMnSi Memory Alloy Layer by Laser Alloying on the Surface of 304 Stainless Steel[D]. Dalian: Dalian Maritime University, 2020

Liu C, Xu P, Zha G, et al. Microstructure and Properties of a Ti Doped Fe-Based Sma Coating Produced by Laser Cladding[J]. Journal of Materials Research and Technology, 2021, 14: 2 441–2 450

Liu S, Zhang M, Zhao G, et al. Microstructure and Properties of Ceramic Particle Reinforced FeCoNiCrMnTi High Entropy Alloy Laser Cladding Coating[J]. Intermetallics, 2022, 140: 107 402

Bhatnagar S, Mullick S, Gopinath M. A Lumped Parametric Analytical Model for Predicting Molten Pool Temperature and Clad Geometry in Preplaced Powder Laser Cladding[J]. Optik, 2021, 247: 168 015

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

All authors declare that there are no competing interests.

Additional information

Funded by the Basic Research Projects in Shanxi Province (No.202103021224183)

Rights and permissions

About this article

Cite this article

Tian, X., Cao, S., Hou, K. et al. Preparation of Laser Cladding Coating Undercooling Cu-based Alloy and Co on Non-equilibrium Solidification Structure. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 39, 463–472 (2024). https://doi.org/10.1007/s11595-024-2902-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-024-2902-x