Abstract

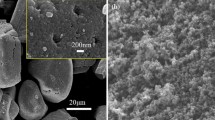

We presented a strategy to prepare spherical tungsten powder by the combination of hydrothermal method and H2 reduction process. In hydrothermal process, the micelle of tetraethylammonium bromide (TEAB) act as spherical templates for the deposition of tungsten oxide, whereas the excessive TEAB inhibit the formation of spherical tungsten oxide due to the dense molecular layer of TEAB on the tungsten oxide particles. Citric acid (CA) can control the formation rate and structure of the tungsten oxide when its concentration is more than 0.2 mol/L, because of its ability to coordinate with tungsten atoms. The synergistic effect of TEAB and CA facilitates the formation of spherical tungsten oxide with nanorod crown. After being treated by H2 at 600 and 650 °C, the tungsten oxide particles are reduced to tungsten particles, which maintain the spherical structure of tungsten oxide and have porous structure.

Similar content being viewed by others

References

Li R, Qin M, Huang H, et al. Fabrication of Fine-grained Spherical Tungsten Powder by Radio Frequency (RF) Inductively Coupled Plasma Spheroidization Combined with Jet Milling[J]. Advanced Powder Technology, 2017, 28(12): 3 158–3 163

Dong Z, Liu N, Ma Z, et al. Preparation of Ultra-fine Grain W-Y2O3 Alloy by an Improved Wet Chemical Method and Two-step Spark Plasma Sintering[J]. Journal of Alloys and Compounds, 2017, 695: 2 969–2 973

Terentyev D, Vilémová M, Yin C, et al. Assessment of Mechanical Properties of SPS-produced Tungsten Including Effect of Neutron Irradiation[J]. International Journal of Refractory Metals and Hard Materials, 2020, 89: 105 207

Butler BG, Paramore JD, Ligda JP, et al. Mechanisms of Deformation and Ductility in Tungsten - A Review[J]. International Journal of Refractory Metals and Hard Materials, 2018, 75: 248–261

Zhang W, Li C. Research of Ultrafine Cemented Carbides for PCB Microdrills[J]. Journal of Wuhan University of Technology-Materials Science, 2021, 36(02): 255–258

Ren C, Fang ZZ, Koopman M, et al. Methods for Improving Ductility of Tungsten - A Review[J]. International Journal of Refractory Metals and Hard Materials, 2018, 75: 170–183

Natarajan S, Gopalan V, Rajan RAA, et al. Effect of Rare Earth Metals (Y, La) and Refractory Metals (Mo, Ta, Re) to Improve the Mechanical Properties of W-Ni-Fe Alloy-A Review[J]. Materials, 2021, 14(7): 1660

Ryu T, Hwang KS, Choi YJ, et al. The Sintering Behavior of Nanosized Tungsten Powder Prepared by a Plasma Process[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(4): 701–704

Li B, Sun Z, Hou G, et al. The Sintering Behavior of Quasi-spherical Tungsten Nanopowders[J]. International Journal of Refractory Metals and Hard Materials, 2016, 56: 44–50

Li R, Qin M, Liu C, et al. Injection Molding of Tungsten Powder Treated by Jet Mill with High Powder Loading: A Solution for Fabrication of Dense Tungsten Component at Relative Low Temperature[J]. International Journal of Refractory Metals and Hard Materials, 2017, 62: 42–46

Ziaee M, Crane NB. Binder Jetting: A Review of Process, Materials, and Methods[J]. Additive Manufacturing, 2019, 28: 781–801

Jiang XL, Boulos MI. Particle Melting, Flattening, and Stacking Behaviors in Induction Plasma Deposition of Tungsten[J]. Transactions of Nonferrous Metals Society of China, 2001, 11(6): 811–816

Wang LZ, Wu JJ, Zhang DJ. Properties Evolution of Additive Manufacture Used Tungsten Powders Prepared by Radio Frequency Induction Plasma[J]. International Journal of Refractory Metals and Hard Materials, 2017, 67: 90–97

Sheng YW, Hao JJ, Guo ZM. Study on Spheroidization of Tungsten Powders by RF Plasma Processing[J]. Advanced Materials Research, 2011, 295–297: 135–139

Qiu WT, Li Z, Xiao Z, et al. Sphericizing Tungsten Particles by Means of Localized Preferential Oxidation and Alkaline Washing[J]. Powder Technology, 2012, 228

Wang CC, Jia CC, Gao P, et al. Spherical Modification of Tungsten Oxide Powder and Its Mechanism Analysis[J]. Rare Metals, 2015, 34(3): 183–188

Yang G, Park SJ. Conventional and Microwave Hydrothermal Synthesis and Application of Functional Materials: A Review[J]. Materials, 2019, 12(7): 1 177

Pourmasoud S, Eghbali-Arani M, Ameri V, et al. Synthesis of Some Transition MWO4 (M: Mn, Fe, Co, Ni, Cu, Zn, Cd) Nanostructures by Hydrothermal Method[J]. Journal of Materials Science: Materials in Electronics, 2019, 30(9): 8 105–8 144

Tehrani FS, Ahmadian H, Aliannezhadi M. Hydrothermal Synthesis and Characterization of WO3 Nanostructures: Effect of Reaction Time[J]. Materials Research Express, 2020, 7(1): 015 911

Fernández-Domene RM, Roselló-Márquez G, Sánchez-Tovar R, et al. Synthesis of WO3 Nanorods Through Anodization in the Presence of Citric Acid: Formation Mechanism, Properties and Photoelectrocatalytic Performance[J]. Surface and Coatings Technology, 2021, 422: 127489

Tan Y, Ma H, Xiong R, et al. Preparation and Photocatalytic Performance of Double-shelled Hollow W18O49@C3N4@Ti3C2 Microspheres[J]. Journal of Wuhan University of Technology -Materials Science Edition, 2021, 36(03): 311–317

Ahmadian H, Tehrani FS, Aliannezhadi M. Hydrothermal Synthesis and Characterization of WO3 Nanostructures: Effects of Capping Agent and pH[J]. Materials Research Express, 2019, 6(10): 105 024

Guo T, Yao MS, Lin YH, et al. A Comprehensive Review on Synthesis Methods for Transition-metal Oxide Nanostructures[J]. Cryst. Eng. Comm., 2015, 17(19): 3 551–3 585

Gu Z, Zhai T, Gao B, et al. Controllable Assembly of WO3 Nanorods/Nanowires into Hierarchical Nanostructures[J]. The Journal of Physical Chemistry B, 2006, 110(47): 23 829–23 836

Le Houx N, Pourroy G, Camerel F, et al. WO3 Nanoparticles in the 5–30 nm Range by Solvothermal Synthesis under Microwave or Resistive Heating[J]. The Journal of Physical Chemistry C, 2010, 114(1): 155–161

Su XT, Xiao F, Lin JL, et al. Hydrothermal Synthesis of Uniform WO3 Submicrospheres Using Thiourea as an Assistant Agent[J]. Materials Characterization, 2010, 61(8): 831–834

Wang L, Huang M, Chen Z, et al. pH-controlled Assembly of Three-dimensional Tungsten Oxide Hierarchical Nanostructures for Catalytic Oxidation of Cyclohexene to Adipic Acid[J]. Cryst. Eng. Comm., 2016, 18(44): 8 688–8 695

Cruywagen JJ, Krüger L, Rohwer EA. Complexation of Tungsten(VI) with Citrate[J]. Journal of the Chemical Society, Dalton Transactions, 1991, (7): 1 727–1 731

Cervilla A, Ramirez JA, Llopis E. Compounds of Tungsten(VI) with Citric Acid: A Spectrophotometric, Polarimetric and Hydrogen-1, Carbon-13 N.M.R. Study of the Formation and Interconversion Equilibria in Aqueous Solution[J]. Transition Metal Chemistry, 1986, 11(5): 186–192

Sungpanich J, Thongtem T, Thongtem S. Photocatalysis of WO3 Nanoplates Synthesized by Conventional-hydrothermal and Microwave-hy-Drothermal Methods and of Commercial WO3 Nanorods[J]. Nanomaterials, 2014, 2014: Article 131

Wang X, Zhang H, Liu L, et al. Controlled Morphologies and Growth Direction of WO3 Nanostructures Hydrothermally Synthesized with Citric Acid[J]. Materials Letters, 2014, 130: 248–251

Alymov MI, Rubtsov NM, Seplyarskii BS, et al. Synthesis of Tungsten Nanopowders and Modes of Their Combustion and Passivation[J]. Mendeleev Communications, 2019, 29(3): 355–357

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

All authors declare that there are no competing interests.

Additional information

Funded by the Key Program of Jiangxi Province on Development and Research(No.20203BBE53058), and the Key Program of Ganzhou City on Development and Research (No.202101125003)

Rights and permissions

About this article

Cite this article

Guo, J., Wen, X., Wu, Y. et al. Preparation of Spherical Tungsten Particles Assisted by Hydrothermal Method. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 38, 1457–1462 (2023). https://doi.org/10.1007/s11595-023-2842-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-023-2842-x