Abstract

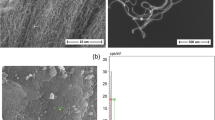

Hybrid nanoSiO2 (HNS) modified cement pastes were explored as a kind of surface protection material (SPM). The carbonation resistance and mechanical properties of SPMs coated samples were tested. Thermogravimetric analysis (TGA), X-ray diffraction (XRD), scanning electron microscope (SEM), and mercury intrusion porosimetry (MIP) were further employed to evaluate the chemical composition and microstructure characteristics of SPM. Besides, thermodynamic modeling was adopted to simulate the changes in the phase assemblages of SPM under the carbonation process. The results showed that SPM with 1 wt% HNS could effectively enhance the carbonation resistance. The incorporation of HNS could densify the microstructure and refine the pore structure. Moreover, the thaumasite can be stable at ambient temperature with the addition of HNS, which is beneficial to maintain alkalinity under the carbonation process.

Similar content being viewed by others

References

Guo X, Wang S, Zhang H. Effects of Fiber Distribution and Content on Performance of Engineered Cementitious Composite (ECC)[J]. Journal of Wuhan University of Technology -Materials Science Edition, 2021, 36(4): 569–577

Xi F, Davis S J, Ciais P, et al. Substantial Global Carbon Uptake by Cement Carbonation[J]. Nature Geoscience, 2016, 9(12): 880–883

Wang X, Yang W, Liu H, et al. Strength and Microstructural Analysis of Geopolymer Prepared with Recycled Geopolymer Powder[J]. Journal of Wuhan University of Technology -Materials Science Edition, 2021, 36(3): 439–445

Benhelal E, Zahedi G, Shamsaei E, et al. Global Strategies and Potentials to Curb CO2 Emissions in Cement Industry[J]. Journal of Cleaner Production, 2013, 51: 142–161

Tang S W, Yao Y, Andrade C, et al. Recent Durability Studies on Concrete Structure[J]. Cement and Concrete Research, 2015, 78: 143–154

V G P, C G V, M N F. Physical and Chemical Characteristics Affecting the Durability of Concrete[J]. Materials Journal, 1991, 88(2): 186–196

Bellezze T, Roventi G, Barbaresi E, et al. Effect of Concrete Carbonation Process on the Passivating Products of Galvanized Steel Reinforcements[J]. Materials and Corrosion, 2011, 62(2): 155–160

Wang Y, Nanukuttan S, Bai Y, et al. Influence of Combined Carbonation and Chloride Ingress Regimes on Rate of Ingress and Redistribution of Chlorides in Concretes[J]. Construction and Building Materials, 2017, 140: 173–183

Jin S, Liu K, Zhang G, et al. Effect of Corrosive Ions (Cl-, SO42−, and Mg2+) on the Nanostructure and Chloride Binding Property of C-A-S-H Gel[J]. Journal of Wuhan University of Technology -Materials Science edition, 2020, 35(6): 1 061–1 072

Basheer L, Kropp J, Cleland D J. Assessment of the Durability of Concrete From Its Permeation Properties: A Review[J]. Construction and Building Materials, 2001, 15(2): 93–103

Pan X, Shi Z, Shi C, et al. A Review on Concrete Surface Treatment Part I: Types and Mechanisms[J]. Construction and Building Materials, 2017, 132: 578–590

Sandrolini F, Franzoni E, Pigino B. Ethyl Silicate for Surface Treatment of Concrete — Part I: Pozzolanic Effect of Ethyl Silicate[J]. Cement and Concrete Composites, 2012, 34(3): 306–312

Thomas J J, Jennings H M, Chen J J. Influence of Nucleation Seeding on the Hydration Mechanisms of Tricalcium Silicate and Cement[J]. The Journal of Physical Chemistry C, 2009, 113(11): 4 327–4 334

Wang Y, Lu L, He Y, et al. Effect of Calcium Silicate Hydrate Seeds on Hydration and Mechanical Properties of Cement[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2021, 36(1): 103–110

Shah S P, Hou P, Konsta-Gdoutos M S. Nano-modification of Cementitious Material: Toward a Stronger and Durable Concrete[J]. Journal of Sustainable Cement-Based Materials, 2016, 5(1–2): 1–22

Du H, Du S, Liu X. Durability Performances of Concrete with Nano-silica[J]. Construction and Building Materials, 2014, 73: 705–712

Zhang B, Tan H, Shen W, et al. Nano-silica and Silica Fume Modified Cement Mortar Used as Surface Protection Material to Enhance the Impermeability[J]. Cement and Concrete Composites, 2018, 92: 7–17

Mei J, Ma B, Tan H, et al. Influence of Steam Curing and Nano Silica on Hydration and Microstructure Characteristics of High-volume Fly Ash Cement System[J]. Construction and Building Materials, 2018, 171: 83–95

Mei J, Tan H, Li H, et al. Effect of Sodium Sulfate and Nano-SiO2 on Hydration and Microstructure of Cementitious Materials Containing High Volume Fly Ash Under Steam Curing[J]. Construction and Building Materials, 2018, 163: 812–825

Du H, Du S, Liu X. Durability Performances of Concrete with Nano-silica[J]. Construction and Building Materials, 2014, 73: 705–712

Sánchez M, Alonso M C, González R. Preliminary Attempt of Hardened Mortar Sealing by Colloidal Nanosilica Migration[J]. Construction and Building Materials, 2014, 66: 306–312

K G, Z P, AH K, et al. Reinforcing Effects of Graphene Oxide on Portland Cemente Paste[J]. J. Mater. Civil Eng., 2014, 27(2): 1–6

Zhuravlev L T. Concentration of Hydroxyl Groups on the Surface of Amorphous Silicas[J]. Langmuir, 1987, 3(3): 316–318

Mora E, González G, Romero P, et al. Control of Water Absorption in Concrete Materials by Modification with Hybrid Hydrophobic Silica Particles[J]. Construction and Building Materials, 2019, 221: 210–218

Gu Y, Wei Z, Ran Q, et al. Characterizing Cement Paste Containing SRA Modified NanoSiO2 and Evaluating Its Strength Development and Shrinkage Behavior[J]. Cement and Concrete Composites, 2017, 75: 30–37

Gu Y, Ran Q, Shu X, et al. Synthesis of NanoSiO2@PCE Core-shell Nanoparticles and Its Effect on Cement Hydration at Early Age[J]. Construction and Building Materials, 2016, 114: 673–680

Gu Y, Xia K, Wei Z, et al. Synthesis of NanoSiO2@graphene-oxide Core-shell Nanoparticles and Its Influence on Mechanical Properties of Cementitious Materials[J]. Construction and Building Materials, 2020, 236: 117 619

Xia K, Gu Y, Jiang L, et al. Carbonation Resistance of Surface Protective Materials Modified with Hybrid NanoSiO2[J]. Coatings (Basel), 2021, 11(3): 269–282

Zhu A, Shi Z, Cai A, et al. Synthesis of Core-shell PMMA-SiO2 Nanoparticles with Suspension-Dispersion-Polymerization in an Aqueous System and Its Effect on Mechanical Properties of PVC Composites[J]. Polymer Testing, 2008, 27(5): 540–547

Li R, Hou P, Xie N, et al. Design of SiO2/PMHS Hybrid Nanocomposite for Surface Treatment of Cement-based Materials[J]. Cement and Concrete Composites, 2018, 87: 89–97

Li R, Hou P, Xie N, et al. Influence of Silica-based Hybrid Material on the Gas Permeability of Hardened Cement Paste[J]. IOP Conference Series: Materials Science and Engineering, 2017, 182: 12 043

Lothenbach B, Kulik D A, Matschei T, et al. Cemdata18: A Chemical Thermodynamic Database for Hydrated Portland Cements and Alkali-activated Materials[J]. Cement and Concrete Research, 2019, 115: 472–506

Powers T C. Structure and Physical Properties of Hardened Portland Cement Paste[J]. Journal of the American Ceramic Society, 1958, 41(1): 1–6

Villain G, Thiery M, Platret G. Measurement Methods of Carbonation Profiles in Concrete: Thermogravimetry, Chemical Analysis and Gammadensimetry[J]. Cement and Concrete Research, 2007, 37(8): 1 182–1 192

Pan X, Shi C, Farzadnia N, et al. Properties and Microstructure of CO2 Surface Treated Cement Mortars with Subsequent Lime-saturated Water Curing[J]. Cement and Concrete Composites, 2019, 99: 89–99

Jennings H M, Kumar A, Sant G. Quantitative Discrimination of the Nano-pore-structure of Cement Paste During Drying: New Insights from Water Sorption Isotherms[J]. Cement & Concrete Research, 2015, 76: 27–36

Wang Q, Li S, Pan S, et al. Effect of Graphene Oxide on the Hydration and Microstructure of Fly Ash-cement System[J]. Construction and Building Materials, 2019, 198: 106–119

Shi Z, Lothenbach B, Geiker M R, et al. Experimental Studies and Thermodynamic Modeling of the Carbonation of Portland Cement, Metakaolin and Limestone Mortars[J]. Cement and Concrete Research, 2016, 88: 60–72

Shah V, Scrivener K, Bhattacharjee B, et al. Changes in Microstructure Characteristics of Cement Paste on Carbonation[J]. Cement and Concrete Research, 2018, 109: 184–197

Acknowledgments

The authors thank Jiangsu Research Institute of Building Science Co., Ltd and the State Key Laboratory of High-performance Civil Engineering Materials for funding this research project.

Funding

Funded by the National Natural Science Foundation of China (Nos.51808188, 52178202, 52108206) and the Fundamental Research Funds for the Central Universities (No.B210201041)

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xia, K., Gu, Y., Jin, W. et al. Carbonation Resistance of Hybrid NanoSiO2 Modified Cementitious Surface Protection Materials. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 37, 855–862 (2022). https://doi.org/10.1007/s11595-022-2607-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-022-2607-y