Abstract

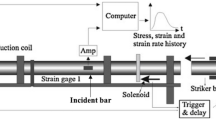

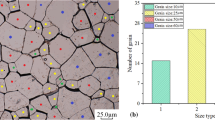

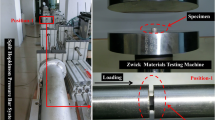

Split Hopkinson pressure bar (SHPB) was utilized to explore the effects of loading strain rate on the dynamic compressing strength of the titanium alloy lattice material. Results reveal that the yield strength of alloy lattice material reaches 342 MPa initially and then drops to 200 MPa before it rebounds to 252 MPa while the loading strain rate correspondingly increases from the static value 1 401/s to 2 084/s. Numerical simulations were then carried out to explore the possible reason underlying. Results show that the lattice structure changed the stress distribution and caused significate stress concentration at finite strain with high strain rate. It is believed that the strain rate strengthening effect and layer-wise failure mode are the main reasons of the above mechanical properties change.

Similar content being viewed by others

References

Queheillalt D T, Murty Y, Wadley H. Mechanical Properties of an Extruded Pyramidal Lattice Truss Sandwich Structure[J]. Scripta Materialia, 2008, 58(1): 76–79

Park S I, Rosen D W, Choi S K, et al. Effective Mechanical Properties of Lattice Material Fabricated by Material Extrusion Additive Manufacturing[J]. Additive Manufacturing, 2014, 1–4: 12–23

Hasan R, Mines R, Fox P. Characterization of Selectively Laser Melted Ti-6Al-4V Micro-Lattice Struts[J]. Procedia Engineering, 2011, 10: 536–541

Simon R G Bates, Ian R Farrow, Richard S Trask. Compressive Behaviour of 3D Printed Thermoplastic Polyurethane Honeycombs with Graded Densities[J]. Materials & Design, 2019, 162: 130–142

Abueidda D W, Elhebeary M, Shiang C S, et al. Mechanical Properties of 3D Printed Polymeric Gyroid Cellular Structures: Experimental and Finite Element Study[J]. Materials & Design, 2019, 165: 486–497

Zhang L, Stefanie F, Stephen D, et al. Energy Absorption Characteristics of Metallic Triply Periodic Minimal Surface Sheet Structures Under Compressive Loading[J]. Additive Manufacturing, 2018, 23: 505–515

Yang L, Raya M, Massimiliano F, et al. Continuous Graded Gyroid Cellular Structures Fabricated by Selective Laser Melting: Design, Manufacturing and Mechanical Properties[J]. Materials & Design, 2019, 162: 394–404

Deshpande V S, Fleck N A, Ashby M F. Effective Properties of the Octet-Truss Lattice Material[J]. Journal of the Mechanics & Physics of Solids, 2001, 49(8): 1747–1769

Chen Y, Fu M H. A Novel Three-Dimensional Auxetic Lattice Meta-Material with Enhanced Stiffness[J]. Smart Materials and Structures, 2017, 26(10): 105–116

Hasan R. Progressive Collapse of Titanium Alloy Micro-Lattice Structures Manufactured Using Selective Laser Melting[J]. University of Liverpool, 2013: 121–128

International Organization for Standardization. Mechanical Testing of Metals-Ductility Testing-Compression Test for Porous and Cellular Metals[S]. ISO 13314-2011, 2011

Kolsky, H. An Investigation of The Mechanical Properties of Materials at Very High Rates of Loading[J]. Proceedings of the Physical Society B, 1949, 62(11): 676

Zhang Y L, Yang S L, Guo B. High Tech Materials for Tanks and Armored Vehicles [J]. Vehicle & Power Technology, 2004(01): 56–62

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Niu, H., You, N., Miao, C. et al. Effects of Strain Rate on the Mechanic Performance of Lattice Materials. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 36, 416–423 (2021). https://doi.org/10.1007/s11595-021-2425-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-021-2425-7