Abstract

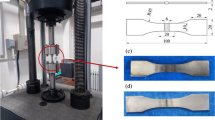

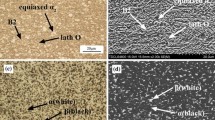

Based on the investigated microstructure of different zones in the annealed automatic gas tungsten arc weld joint of TA16 and TC4 titanium alloys, the mechanical property of them was assessed under fatigue crack growth rate tests. For evaluation of fatigue crack growth rate, three points bending specimens were used. The correlation between the range of stress intensity factor and crack growth rate was determined in different zones of the annealed weld joint. Fatigue crack growth rates were obviously different in different zones of weld joint of dissimilar titanium alloys, due to their different microstructures. Scanning electron microscope examinations were conducted on the fracture surface in order to determine the relevant fracture mechanisms and crack growth mechanisms with respect to the details of microstructure.

Similar content being viewed by others

References

Castany P, Gloriant T, Sun F, et al. Design of Straintransformable Titanium Alloys[J]. Comptes Rendus Physique, 2018, 19(8): 710–720

Ma TF, Zhou X, Du Y, et al. High Temperature Deformation and Microstructural Evolution of Core-shell Structured Titanium Alloy[J]. Journal of Alloys and Compounds, 2019, 775: 316–321

Singh P, Pungotra H, Kalsi NS. On the Characteristics of Titanium Alloys for the Aircraft Applications[J]. Materials Today: Proceedings, 2017, 4(8): 8 971–8 982

Lee HK, Han HS, Son KJ, et al. Optimization of Nd: YAG Laser Welding Parameters for Sealing Small Titanium Tube Ends[J]. Materials Science and Engineering: A, 2006, 415(1–2): 149–155

Yixuan L, Fulin H. The Connection Characteristics of Titanium Alloy Pipes in Vibration Environment[C]. In: 5th International Conference on Measurement Instrumentation and Automation, 2016: 43–47

Sun B, Qiu M, Tian J, et al. Research on Design and Process of External Titanium Alloy Tube for Aeroengine[J]. Aeronautical Manufacturing Technology, 2015, 493(z2): 124–128

Zhao P, Fu L, Chen H. Low Cycle Fatigue Properties of Linear Friction Welded Joint of TC11 and TC17 Titanium Alloys[J]. Journal of Alloys and Compounds, 2016, 675: 248–256

Wang SQ, Liu JH, Chen DL. Tensile and Fatigue Properties of Electron Beam Welded Dissimilar Joints between Ti-6Al-4V and BT9 Titanium Alloys[J]. Materials Science and Engineering: A, 2013, 584: 47–56

Wang SQ, Liu JH, Lu ZX, et al. Cyclic Deformation of Dissimilar Welded Joints between Ti-6Al-4V and Ti17 Alloys: Effect of Strain Ratio[J]. Materials Science and Engineering: A, 2014, 598: 122–134

Tan L, Yao Z, Zhou W, et al. Microstructure and Properties of Electron Beam Welded Joint of Ti-22Al-25Nb/TC11[J]. Aerospace Science and Technology, 2010, 14(5): 302–306

Lei ZL, Dong ZJ, Chen YB, et al. Microstructure and Mechanical Properties of Laser Welded Ti-22Al-27Nb/TC4 Dissimilar Alloys[J]. Materials Science and Engineering: A, 2013, 559: 909–916

Wen GD, Ma TJ, Li WY, et al. Strain-controlled Fatigue Properties of Linear Friction Welded Dissimilar Joints between Ti-6Al-4V and Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Alloys[J]. Materials Science and Engineering: A, 2014, 612: 80–88

Zou J, Cui Y, Yang R. Diffusion Bonding of Dissimilar Intermetallic Alloys Based on Ti2AlNb and TiAl[J]. Journal of Materials Science & Technology, 2009, 25(6): 819–824

Huang Y, Jialin G, Qing L, et al. Study of δ-hydrides in Ti-2Al-2.5Zr and Ti-4Al-2V Alloys[J]. Rare Metals, 2006, 25(1): 16–20

Hang W, Yan LX, Qiao YS, et al. Low Cycle Fatigue Behaviors and Microstructures of Ti-2Al-2.5Zr with Fine Grain at RT and 77K[J]. Acta Metallurgica Sinica, 2009, 45(4): 434–441

Radecka A, Bagot PAJ, Martin TL, et al. The Formation of Ordered Clusters in Ti-7Al and Ti-6Al-4V[J]. Acta Materialia, 2016, 112: 141–149

Shao L, Wu SJ, Peng WY, et al. Microstructure and Mechanical BeHavior of an Annealed Automatic Gas Tungsten Arc Weld Joint of TA16 and TC4 Titanium Alloys[J]. Materials Research Express, 2019, 6(5): 056523

Ahadi A, Sun Q. Grain Size Dependence of Fracture Toughness and Crack-growth Resistance of Superelastic NiTi[J]. Scripta Materialia, 2016, 113: 171–175

Shi J, Chopp D, Lua J, et al. Abaqus Implementation of Extended Finite Element Method using a Level Set Representation for Three-dimensional Fatigue Crack Growth and Life Predictions[J]. Engineering Fracture Mechanics, 2010, 77(14): 2 840–2 863

Li S, Kang Y, Zhu G, et al. Microstructure and Fatigue Crack Growth Behavior in Tungsten Inert Gas Welded DP780 Dual-phase Steel[J]. Materials & Design, 2015, 85: 180–189

Sudhakar KV, Dwarakadasa ES. A Study on Fatigue Crack Growth in Dual Phase Martensitic Steel in Air Environment[J]. Bull Mater. Sci., 2000, 23: 193–199

Balasubramanian V, Lakshminarayanan AK, Malarvizhi S. Effect of Welding Processes on Fatigue Behaviour of AISI 409M Grade Ferritic Stainless Steel Joints[J]. Advanced Materials Research, 2013, 794: 391–412

Paris P, Erdogan F. A Critical Analysis of Crack Propagation Laws[J]. J. Basic Eng., 1963, 85: 528–533

Wang YL, Pan QL, Wei LL, et al. Effect of Retrogression and Reaging Treatment on the Microstructure and Fatigue Crack Growth Behavior of 7050 Aluminum Alloy Thick Plate[J]. Materials & Design, 2014, 55: 857–863

Song ZQ, He Q, Ma E, et al. Fatigue Endurance Limit and Crack Growth Behavior of a High-toughness Zr61Ti2Cu25Al12 Bulk Metallic Glass[J]. Acta Materialia, 2015, 99: 165–175

KoneČNÁ R, Bubenko L, Nicoletto G. Microstructure vs. Near-threshold Fatigue Crack Growth Behavior of an Heat-treated Ductile Iron[J]. Materials Science, 2012, 18(1): 23–27

Farabi N, Chen DL, Li J, et al. Microstructure and Mechanical Properties of Laser Welded DP600 Steel Joints[J]. Materials Science and Engineering: A, 2010, 527(4–5): 1 215–1 222

Shen F, Wang B, Yi D, et al. Effects of Heating Rate during Solid-solution Treatment on Microstructure and Fatigue Properties of AA2524 T3 Al-Cu-Mg Sheet[J]. Materials & Design, 2016, 104: 116–125

Zheng ZQ, Cai B, Zhai T, et al. The Behavior of Fatigue Crack Initiation and Propagation in AA2524-T34 Alloy[J]. Materials Science and Engineering: A, 2011, 528(4–5): 2 017–2 022

Shen F, Yi D, Jiang Y, et al. Semi-quantitative Evaluation of Texture Components and Fatigue Properties in 2524 T3 Aluminum Alloy Sheets[J]. Materials Science and Engineering: A, 2016, 657: 15–25

Wang X, Shi Q, Wang X, et al. The Influences of Precrack Orientations in Welded Joint of Ti-6Al-4V on Fatigue Crack Growth[J]. Materials Science and Engineering: A, 2010, 527(4–5): 1 008–1 015

Balasubramanian TS, Balasubramanian V, Muthu Manickam MA. Fatigue Crack Growth Behaviour of Gas Tungsten Arc, Electron Beam and Laser Beam Welded Ti-6Al-4V Alloy[J]. Materials & Design, 2011, 32(8–9): 4 509–4 520

Ping G, Yong QZ, Wei DZ. Fatigue Crack Growth Behavior in TC4-DT Titanium alloy with Different Lamellar Microstructures[J]. Rare Metal Materials and Engineering, 2015, 44(2): 277–281

Hanlon T, Tabachnikova E, Suresh S. Fatigue Behavior of Nanocrystalline Metals and Alloys[J]. International Journal of Fatigue, 2005, 27(10–12): 1 147–1 158

Singh A, Tang L, Dao M, et al. Fracture Toughness and Fatigue Crack Growth Characteristics of Nanotwinned Copper[J]. Acta Materialia, 2011, 59(6): 2 437–2 446

Ghonem H. Microstructure and Fatigue Crack Growth Mechanisms in High Temperature Titanium Alloys[J]. International Journal of Fatigue, 2010, 32(9): 1 448–1 460

Suresh S. Fatigue Crack Deflection and Fracture Surface Contact: Micromechanical Models[J]. Metallurgical Transactions A, 1985, 16: 249–260

Jinkeun Oh NJK, Sunghak L, Eui WL. Correlation of Fatigue Properties and Microstructure in Investment Cast Ti-6Al-4V Welds[J]. Materials Science and Engineering: A, 2003, 340: 232–242

Verdhan N, Bhende DD, Kapoor R, et al. Effect of Microstructure on the Fatigue Crack Growth Behaviour of a Near-α Ti Alloy[J]. International Journal of Fatigue, 2015, 74: 46–54

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded in Part by the Grant from Technology and Industry for National Defense, China (No. AXXD1818)

Rights and permissions

About this article

Cite this article

Shao, L., Wu, S., Peng, W. et al. Fatigue Crack Growth Behavior of Different Zones in an Annealed Automatic Gas Tungsten Arc Weld Joint of TA16 and TC4 Titanium Alloys. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 35, 1090–1097 (2020). https://doi.org/10.1007/s11595-020-2359-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-020-2359-5