Abstract

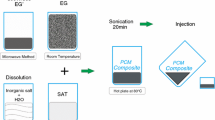

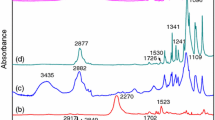

A 1-octadecanol (OD)/1,3:2,4-di-(3,4-dimethyl) benzylidene sorbitol (DMDBS)/expander graphite (EG) composite was prepared as a form-stable phase change material (PCM) by vacuum melting method. The results of field emission-scanning electron microscopy (FE-SEM) showed that 1-octadecanol was restricted in the three-dimensional network formed by DMDBS and the honeycomb network formed by EG. X-ray diffraction (XRD) and Fourier transform infrared spectroscopy (FT-IR) results showed that no chemical reaction occurred among the components of composite PCM in the preparation process. The gel-to-sol transition temperature of the composite PCMs containing DMDBS was much higher than the melting point of pure 1-octadecanol. The improvements in preventing leakage and thermal stability limits were mainly attributed to the synergistic effect of the three-dimensional network formed by DMDBS and the honeycomb network formed by EG. Differential scanning calorimeter (DSC) was used to determine the latent heat and phase change temperature of the composite PCMs. During melting and freezing process the latent heat values of the PCM with the composition of 91% OD/3% DMDBS/6% EG were 214.9 and 185.9 kJ·kg−1, respectively. Its degree of supercooling was only 0.1 °C. Thermal constant analyzer results showed that its thermal conductivity (κ) changed up to roughly 10 times over that of OD/DMDBS matrix.

Similar content being viewed by others

References

Kenisarin M M, Kenisarina K M. Form-stable Phase Change Materials for Thermal Energy Storage[J]. Renew. Sust. Energy Rev., 2012,16: 1 999∓2 040

Hasnain S M. Review on Sustainable Thermal Energy Storage Technologies, Part I: Heat Storage Materials and Techniques[J]. Energy Convers. Manage., 1998, 39: 1 127–1 138

Sharma A, Tyagi V V, Chen C R, et al. Review on Thermal Energy Storage with Phase Change Materials and Applications[J]. Renew. Sust. Energy Rev., 2009, 13: 318–345

Mettawee E, Assassa G. Experimental Study of a Compact PCM Solar Collector[J]. Energy, 2006, 31: 2 958–2 968

Francis A, Neil H, Philip E, et al. A Review of Materials, Heat Transfer and Phase Change Problem Formulation for Latent Heat Thermal Energy Storage Systems (LHTESS)[J]. Renew. Sust. Energy Rev., 2010, 14: 615–628

Cabeza L F, Castell A, Barreneche C, et al. A. I. Fernandez, Materials Used as PCM in Thermal Energy Storage in Buildings: a Review[J]. Renew. Sust. Energy Rev., 2011, 15: 1 675–1 695

Mohammed M F, Amar M K, Siddique A K R, et al. A Review on Phase Change Energy Storage: Materials and Applications[J]. Energy Convers. Manage, 2004, 45: 1 597–1 615

Tunçbilek K, Sari A, Tarhan S, et al. Lauric and Palmitic Acids Eutectic Mixture as Latent Heat Storage Material for Low Temperature Heating Applications[J]. Energy, 2005, 30: 677–692

Zalba B, Marin J M, Cabeza L F, et al. Review on Thermal Energy Storage with Phase Change: Materials, Heat Transfer Analysis and Applications[J]. Appl. Therm. Eng., 2003, 23: 251–283

Ahmet S, Cemil A, Alper B. Development, Characterization, and Latent Heat Thermal Energy Storage Properties of Neopentyl Glycol-Fatty Acid Esters as New Solid-Liquid PCMs[J]. Ind. Eng. Chem. Res., 2013, 52: 18 269–18 275

Regin A F, Solanki A C, Saini J S. Heat Transfer Characteristics of Thermal Energy Storage System Using PCM Capsules: A Review[J]. Renew. Sust. Energy Rev., 2008, 12: 2 438–2 458

Sarier N, Onder E. Organic Phase Change Materials and Their Textile Applications: An Overview[J]. Thermochim. Acta, 2012, 540: 7–60

Hasan A, Sayigh A A. Some Fatty Acids as Phase Change Thermal Energy Storage Materials[J]. Renew. Energy, 1994, 4: 69–76

Sharma A, Tyagi V V, Chen C R, et al. Review on Thermal Energy Storage with Phase Change Materials and Applications[J]. Renew. Sust. Energy Rev., 2009, 13: 318–345

Zhang L, Zhu J Q, Zhou W B, et al. Characterization of Polymethyl Methacrylate/Polyethylene Glycol/Aluminum Nitride Composite as Form-stable Phase Change Material Prepared by In Situ Polymerization Method[J]. Thermochim. Acta, 2011, 524: 128–134

Yavari F, Fard H R, Pashayi K, et al. Enhanced Thermal Conductivity in a Nanostructured Phase Change Composite due to Low Concentration Graphene Additives[J]. Phys. Chem., 2011, 115: 8 753–8 758

Sari A, Karaipekli A. Thermal Conductivity and Latent Heat Thermal Energy Storage Characteristics of Paraffin/Expanded Graphite Composite as Phase Change Material[J]. Appl. Thermal Eng., 2007, 27: 1 271–1 277

Molefia J A, Luyt A S, Krupa I. Comparison of LDPE, LLDPE and HDPE as Matrices for Phase Change Materials Based on a Soft Fischer-Tropsch Paraffin Wax[J]. Thermochim. Acta, 2010, 500: 88–92

Alkan C, Sari A. Poly(ethylene glycol)/Acrylic Polymer Blends for Latent Heat Thermal Energy Storage[J]. AIChE J., 2006, 52: 3 310–3 314

Niu L B, Bai G Y, Song J. 1,3:2,4-di-(3,4-dimethyl) Benzylidene Sorbitol Organogels Used as Phase Change Materials: Solvent Effects on Structure, Leakage and Thermal Performance[J]. RSC Advances, 2015, 5: 21 733–21 739

Zhang L, Zhu J Q, Zhou W B, et al. Thermal and Electrical Conductivity Enhancement of Graphite Nanoplatelets on Form-stable Polyethylene Glycol/Polymethyl Methacrylate Composite Phase Change Materials[J]. Energy, 2012, 39: 294–302

Tian T, Song J, Niu L B, et al. Preparation and Properties of 1-tetradecanol/1,3:2,4-di-(3,4-dimethyl) Benzylidene Sorbitol Gelatinous Form-stable Phase Change Materials[J]. Thermochim. Acta, 2013, 554: 54–58

Takahashi A, Sakai M, Kato T. Melting Temperature of Thermally Reversible Gel. VI. Effect of Branching on the Sol-gel Transition of Polyethylene Gels[J]. Polym. J., 1980, 12: 335–341

Beginn U. Applicability of Frozen Gels from Ultra High Molecular Weight Polyethylene and Paraffin Waxes as Shape Persistent Solid/Liquid Phase Change Materials[J]. Macromol. Mater. Eng., 2003, 288: 245–251

Edwards W, Lagadec C A, Smith D K. Solvent-Gelator Interactionsusing Empirical Solvent Parameters to Better Understand the Self-assembly of Gel-phase Materials[J]. Soft Mater., 2011, 7(1): 110–117

Ventolà L, Ramirez M, Calvet T, et al. Polymorphism of N-Alkanols: 1-Heptadecanol, 1-Octadecanol, 1-Nonadecanol, and 1-Eicosanol[J]. Chem. Mater., 2002, 14: 508–517

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by Science and Technology Support Program of Hubei Province of China (No. 2015BAA111)

Rights and permissions

About this article

Cite this article

Xu, J., Cheng, X., Li, Y. et al. Preparation and Properties of l-octadecanol/1,3:2,4-di-(3,4-dimethyl) Benzylidene Sorbitol/Expanded Graphite Form-stable Composite Phase Change Material. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 728–735 (2019). https://doi.org/10.1007/s11595-019-2110-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-019-2110-2