Abstract

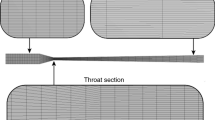

A new type of adjustable nozzle with an annulus clearance between the surfaces of a revolved solid and the matched hole was analyzed, which contained matching parts, regulating parts, guiding elements, and sealing part. The general regulating function of the adjustable nozzle was derived and the regulating and matching characteristics were also analyzed. Through the analysis, it was concluded that the matching-profile curve of either the revolved body or matched hole should be chosen as a straight line in order to keep the linear regulating feature. Moreover, the multi-annulus-clearance nozzle was designed, and some experiments were carried out on preparing budesonide particles with the nozzle. According to the experimental results, it was proved that the annulus nozzles is practical in preparing micro-particles by supercritical fluid precipitation method.

Similar content being viewed by others

References

Jung J and Perrut M. Particle Design Using Supercritical Fluids: Literature and Patent Survey[J]. J.Supercrit. Fluid., 2001, 20: 179–219

Domingo C and Berends E. Precipitation of Ultrafine Organic Crystals from the Rapid Expansion of Supercritical Solutions over a Capillary and a Frit Nozzle[J]. J.Supercrit. Fluid., 1997, 10: 39–55

Yildiz N, Tuna Ş, Döker O, et al. Micronization of Salicylic Acid and Taxol (paclitaxel) by Rapid Expansion of Supercritical Fluids (RESS) [J]. J. Supercrit. Fluid., 2007, 41: 440–451

Montes A, Gordillo MD, Pereyra, C, et al. Supercritical CO2 Precipitation of Poly(l-lactic acid) in a Wide Range of Miscibility[J]. J.Supercrit. Fluid., 2013, 81: 236–244

Tom J W, Debenedetti P G and Jerome R. Precipitation of Poly (L-lactic acid) and Composite Poly (L-lactic acid)-pyrene Particles by Rapid Expansion of Supercritical Solutions[J]. J. Supercrit. Fluid., 1994, 3: 9–29

Huang JT and Moriyoshi T. Fabrication of Fine Powders by Ress with a Clearance Nozzle[J]. J.Supercrit. Fluid., 2006, 37: 292–297

Hezave Z and Esmaeilzadeh F. Micronization of Drug Particles via RESS Process[J]. J.Supercrit. Fluid., 2010, 52: 84–98

Dixon DJ, Luna-barcenas G and Johnston KP. Microcellular Microspheres and Microballoons by Precipitation with a Vapour-liquid Compressed Fluid Antisolvent[J]. Polymer, 1994, 35: 3 998–4 005

Reverchon E and Della Porta G. Particle Design Using Supercritical Fluids[J]. Chem. Eng. Tech., 2003, 26: 840–845

Gokhale A, Khusid B, Dave RN, et al. Effect of Solvent Strength and Operating Pressure on the Formation of Submicrometer Polymer Particles in Supercritical Microjets[J]. J.Supercrit. Fluid., 2007, 43: 341–356

Debenedetti PG, Lim Gio-bin and Prud’homme RK. Preparation of Protein Microparticles by Supercritical Fluid Precipitation[P]. US Patent 6, 063, 910. 2000–05–16

Hanna M and York P. Method and Apparatus for the Formation of Particles[P]. US Patent 6,063,138. 2000–05–16

Mawson S, Kanakia S and Johnston KP. Coaxial Nozzle for Control of Particle Morphology in Precipitation with a Compressed Fluid Antisolvent [J]. J. Appl. Polym. Sci., 1997, 64: 2 105–2 118

Bouchard A, Jovanovićb N, Boerc AH, et al. Effect of the Spraying Conditions and Nozzle Design on the Shape and Size Distribution of Particles Obtained with Supercritical Fluid Drying[J]. Eur. J. Pharm. Biopharm., 2008, 70: 389–401

Baldyga J, Kubicki D, Shekunov BY, et al. Mixing Effects on Particle Formation in Supercritical Fluids[J]. Chem. Eng. Res. Des., 2010, 88: 1 131–1141

Jarmer DJ, Lengsfeld CS and Randolph T W. Manipulation of Particle Size Distribution of Poly (L-lactic acid) Nanoparticles with a Jetswirl Nozzle during Precipitation with a Compressed Antisolvent[J]. J.Supercrit. Fluid., 2003, 27: 317–336

Liu Y, Qu YP, Wang WQ, et al. The Nozzle Design for Superfine Powders Preparation Using Supercritical Fluids Technology[J]. Chinese powder Industry, 2008, 4: 18–22 (in Chinese)

Wang WQ, Liu Yan, Li AJ, et al. Nozzle in Inside-and-outside Mixing Mode for Preparing Superfine Particles by SCF Method[P]. Chinese Patent 200510043476.4. 2008–10–22

Liu Y, Zhang M, Wang WQ, et al. A Type of Combination Nozzle for Preparing Superfine Particles by SCF Method[P]. Chinese Patent 201010516612.8. 2012–08–01

Qu YP, Wang WQ, Liu Y, et al. The Refining and Adjustable Annulusclearance Nozzle for Superfine Materials Preparation Using Supercritical Fluids[P]. Chinese Patent 201010582308.3. 2012–10–03

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Science and Technology Development Plan of Shandong Province (No.2014GGX108001)

Rights and permissions

About this article

Cite this article

Qu, Y., Liu, Y., Liu, S. et al. Structural and regulating characteristics of adjustable annulus-clearance nozzle used in supercritical fluid precipitation. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 1487–1492 (2017). https://doi.org/10.1007/s11595-017-1773-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1773-9