Abstract

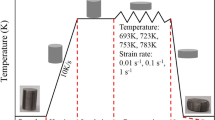

Hot deformation behavior of as-cast Mn18Cr18N austenitic stainless steel was studied in the temperature range of 950-1200 °C and strain rate range of 0.001-1 s-1 using isothermal hot compression tests. The true stress-strain curves of the steel were characterized by hardening and subsequent softening and varied with temperatures and strain rates. The hot deformation activation energy of the steel was calculated to be 657.4 kJ/mol, which was higher than that of the corresponding wrought steel due to its as-cast coarse columnar grains and heterogeneous structure. Hot processing maps were developed at different plastic strains, which exhibited two domains with peak power dissipation efficiencies at 1150 °C/0.001 s-1 and 1200 °C/1 s-1, respectively. The corresponding microstructures were analyzed by optical microscopy (OM), scanning electron microscopy (SEM), and electron backscatter diffraction (EBSD). It has been confirmed that dynamic recrystallization (DRX) controlled by dislocation slipping and climbing mechanism occurs in the temperature and strain rate range of 1050-1200 °C and 0.001-0.01 s-1; And DRX controlled by twinning mechanism occurs in the temperature and strain rate range of 1100-1200 °C, 0.1-1 s-1. These two DRX domains can serve as the hot working windows of the as-cast steel at lower strain rates and at higher strain rates, respectively. The processing maps at different strains also exhibit that the instability region decreases with increasing strain. The corresponding microstructures and the less tensile ductility in the instability region imply that the flow instability is attributed to flow localization accelerated by a few layers of very fine recrystallized grains along the original grain boundaries.

Similar content being viewed by others

References

Wu S, Wang H, An C, et al. Microstructure and Properties of 1Mn18Cr18N Steel Used for Retaining Ring[J]. Heat Treatment of Metals, 2016, 41(7): 37–40

Sun G, Zhang Y, Sun S, et al. Plastic Flow Behavior and Its Relationship to Tensile Mechanical Properties of High Nitrogen Nickel-free Austenitic Stainless Steel[J]. Materials Science & Engineering A, 2016, 662: 432–442

Lu XY, Wang X, Jiang Y, et al. Effects of Nitrogen on Microstructure and Properties of Ultra-fine Grain Austenitic Stainless Steel[J]. Hot Working Technology, 2014, 43(6):72–75

B. Kartik, R. Veerababu, M. Sundararaman, et al. Effect of High Temperature Ageing on Microstructure and Mechanical Properties of a Nickel-free High Nitrogen Austenitic Stainless Steel[J]. Materials Science & Engineering A, 2015, 642: 288–296

Zeng XQ, Liu RZ, Zhu R, et al. Research on Hot Working Character of High Nitrogen Steel[J]. Industrial Heating, 2016, 45(2): 1–11

Ji CT, Fan YH, Chen ZW, et al. Deformation and Recrystallization of 0Cr18Mn18N0.6 Nickel Free High Nitrogen Austenitic Stainless Steel[J]. Hot Working Technology, 2015, 44(21): 47–50

Jiang ZH, Liu XH, Zhang Y, et al. Relationship between Thermoplasticity and Related Structure of Mn18Cr18N ESR Steel As-Cast[J]. Journal of Iron & Steel Research, 1998, 10(6): 37–40

Wang HT, Zhou CD, Ren TL, et al. The Hot Deformation Behavior of As-cast Austenitic Stainless Steel 1Mn18Cr18N[J]. Large Electric Machine & Hydraulic Turbine, 2014(5): 31–34

Prasad YVRK, Rao K P, Gupta M. Hot Workability and Deformation Mechanisms in Mg/nano-Al2O3 Composite[J]. Composites Science and Technology, 2009, 69(7): 1070–1076

Sundar RS, Sastry DH, Prasad YVRK. Hot Workability of As-cast Fe 3 Al–2.5%Cr Intermetallic Alloy[J]. Materials Science & Engineering A, 2003, 347(s 1–2):86–92

Suresh K, Rao KP, Prasad YVRK, et al. Study of Hot Forging Behavior of As-cast Mg–3Al–1Zn–2Ca Alloy Towards Optimization of Its Hot Workability[J]. Materials & Design, 2014, 57(5): 697–704

Mcqueen HJ, Blum W. Dynamic Recovery: Sufficient Mechanism in the Hot Deformation of Al (<99.99)[J]. Materials Science & Engineering A, 2000, 290(1-2): 95–107

Mcqueen HJ, Imbert CAC. Dynamic Recrystallization: Plasticity Enhancing Structural Development[J]. Journal of Alloys & Compounds, 2004, 378(1-2): 35–43

Sivakesavam O, Prasad YVRK. Characteristics of Superplasticity Domain in the Processing Map for Hot Working of As-cast Mg-11.5Li-1.5Al Alloy[J]. Materials Science & Engineering A, 2002, 323(1-2): 270–277

McQueen HJ, Ryan ND. Constitutive Analysis in Hot Working[J]. Materials Science & Engineering A, 2002, 322(1-2): 43–63

Humphreys FJ, Hatherly M. Recrystallization and Related Annealing Phenomena (Second Edition)[J]. 2004, 64(9): 219–224

Mcqueen HJ. Development of Dynamic Recrystallization Theory[J]. Materials Science & Engineering A, 2004, 387–389(1): 203–208

Mataya MC, Nilsson ER, Brown EL, et al. Hot Working and Recrystallization of As-cast 316L[J]. Metallurgical and Materials Transactions A, 2003, 34(8): 1683–1703

Mataya MC, Nilsson ER, Brown EL, et al. Hot Working and Recrystallization of As-cast 316L[J]. Metallurgical and Materials Transactions A, 2003, 34(8): 3021–3041

Campbell GT, Abrahamson EP, Grant NJ. The Recrystallization Behavior of an Austenitic Stainless Steel Ingot Structure Due to Hot Deformation[J]. Metallurgical and Materials Transactions B, 1974, 5(8): 1875–1881

Prasad YVRK. Hot Working Guide. A Compendium of Processing Maps[M]. OH: ASM International Materials Park, 2015

Prasad YVRK. Processing Maps: A Status Report[J]. Journal of Materials Engineering and Performance, 2013, 22(10): 2867–2874

Sun CY, Li YM, Xiang Y, et al. Hot Deformation Behavior and Hot Processing Maps of 316LN Stainless Steel[J]. Rare Metal Materials & Engineering, 2016, 45(3): 688–695

Venugopal S, Sivaprasad PV, Vasudevan M, et al. Validation of Processing Maps for 304L Stainless Steel Using Hot Forging, Rolling and Extrusion[J]. Journal of Materials Processing Technology, 1996, 59(59): 343–350

Sivaprasad PV, Venugopal S, Sridhar Venugopal, et al. Validation of Processing Maps for a 15Cr-15Ni-2.2Mo-0.3Ti Austenite Stainless Steel Using Hot Forging and Rolling Tests[J]. Journal of Materials Processing Technology, 2003, 132(1-3): 262–268

Guo YF, Liu JS, He WW. Dynamic Recrystallization Behavior and Power Dissipation Map of Mn18Cr18N Retaining Ring Steel[J]. Materials for Mechanical Engineering, 2010, 34(3): 5–8

Wang CJ, Feng H, Zheng WJ, et al. Dynamic Recrystallization Behavior and Microstructure Evolution of AISI 304N Stainless Steel[J]. Iron Steel Res. Int., 2013, 20(10): 107–112

Xi T, Yang C, Shahzad M B, et al. Study of the Processing Map and Hot Deformation Behavior of a Cu-bearing 317LN Austenitic Stainless Steel[J]. Materials & Design, 2015, 87: 303–312

Qin FM, Zhu H, Wang ZX, et al. Dislocation and Twinning Mechanisms for Dynamic Recrystallization of As-cast Mn18Cr18N Steel[J]. Materials Science & Engineering A, 2016, 684: 634–644

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China(No.51575372)

Rights and permissions

About this article

Cite this article

Chen, H., Wang, Z., Qin, F. et al. Hot deformation behavior and processing maps of as-cast Mn18Cr18N steel. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 935–943 (2017). https://doi.org/10.1007/s11595-017-1693-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1693-8