Abstract

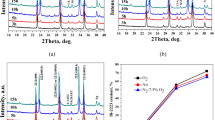

Powder in tube process (PIT) was adopted for the fabrication of single filament Bi-2223 tapes, and a heat treatment process including the first heat treatment (HT1), intermediate rolling (IR), and second heat treatment (HT2) was performed. The phase evolution mechanism and microstructure changes during these heat treatment processes were systematically discussed. The influences of HT1 parameters on the phase evolution process of Bi-2223 tapes were discussed. With the optimized HT1 process, a proper Bi-2223 content of about 90% was achieved. HT2 process was also optimized by adding a post annealing process. An obvious increase of current capacity was obtained due to the enhancement of intergrain connections. Single filament Bi-2223 tapes with the critical current of I c-90 A were fabricated with the optimized sintering process.

Similar content being viewed by others

References

Maeda H, Tanaka Y, Fukutomi M, et al. High-Tc Bi-based Oxide Superconductors[J]. Jpn. J. Appl. Phys., 1988, 27: L209–L212

Hamabe M, Sugino M, Watanabe H, et al. Critical Current and its Magnetic Field Effect Measurement of HTS Tapes Forming DC Superconducting Cable[J]. IEEE Trans. Appl. Supercond., 2011, 21: 1038–1041

Yanagisawa Y, Xu Y, Iguchi S, et al. Combination of High Hoop Stress Tolerance and a Small Screening Current-induced Field for an Advanced Bi-2223 Conductor Coil at 4.2 K in an External Field[J]. Supercond. Sci. Technol., 2015, 28: 125005: 1–8

Ohya M, Inagaki Y, Tatamidani K, et al. Japan’s First Live Power Transmission Using 3-in-one Superconducting Cable (High-temperature Superconducting Cable Demonstration Project)[J]. SEI Technical Review, 2013, 76: 45–54

Hu QY, Liu HK, Dou SX. Fabrication of Ag Sheathed Bi-2223 Tape with Supercold Rolling Process[J]. Physica C., 1997, 274: 204–208

Chen XP, Yu XW, Xiao R, et al. Critical Current Enhancement in Bi-2223/Ag Superconducting Tapes by Controlling its First Sintering Process[J]. J. Alloy. Compd., 2010, 509: 1090–1093

Pu MH, Feng Y, Zhang P X, et al. Enhanced the Flux Pinning in Bi-2223/Ag by Induced Cr-ion Defects[J]. Physica C, 2003, 386: 41–46

Hua L, Yoo J, Ko J, et al. Microstructure and Phase Evolution of Ultrafine MgO Doped Bi-2223/Ag Tapes[J]. Physica C, 1997, 291: 149–154

Guo YC, Tanaka Y, Kuroda T, et al. Addition of Nanometer SiC in the Silver-sheathed Bi2223 Superconducting tapes[J]. Physica C, 1999, 311: 65–74

Osamura K, Nonaka S, Matsui M. Non Superconducting Phases and Their Influence on Critical Current Density in Ag/Bi2223 Tapes[J]. Physica C, 1996, 257: 79–85

Chen XP, Liu M, Shang LM, et al. Effects of Heating Rate on the Phase and Microstructure Evolution in Bi-2223/Ag/Ni Superconducting Tapes[J]. Ceramics International, 2014, 40: 7293–7296

Majewski P, Hettich B, Schulze K. The Phase Equilibria of Bi2Sr2Ca2Cu3O10 in the System Bi2O3-SrO-CaO-CuO[J]. Physica C, 1991, 185–189: 469–470

Ma X, Hao Q, Liu G, et al. Influences of Pb Content on the Critical Current of Bi-2223 Multi-filamentary Tapes[J]. Mater. Lett., 2016, 162: 5–8

Deng H, Hua PW, Dong C, et al. Phase Transformation and Critical Current Density of (Bi,Pb)-2223/Ag Superconducting Tapes by a Low Temperature-Low Oxygen Pressure Post-annealing Method[J]. Physica C, 2000, 339: 171–180

Qu TM, Zhao L, Wang XC, et al. The Influence of Post-annealing on the Pb3(Bi0.5Sr2.5)Ca2CuOyPhase Evolution and Superconducting Properties of (Bi,Pb)-2223/Ag Tapes[J]. Physica C, 2007, 463–465: 833–836

Qu T M, Han Z, Flukiger R. Phase Evolution During Post-annealing and its Influence on Critical Currents of (Bi,Pb)-2223/Ag Tapes[J]. Physica C, 2006, 444: 71–76

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China(No.51472206), the National ITER Program of China(2015GB115001), and the Program for Innovative Research Team in Shaanxi Province(No.2013KCT-07)

Rights and permissions

About this article

Cite this article

Bai, L., Zhang, S., Li, C. et al. Phase evolution study and optimization of the heat treatment process for high current capacity Bi-2223 tapes. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 862–865 (2017). https://doi.org/10.1007/s11595-017-1680-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1680-0