Abstract

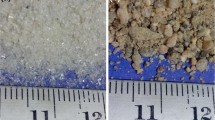

The compressive strength of mortar containing glass powder (GP) and/or glass aggregate (GA) was tested, and its microstructure was also studied by thermogravimetric and differential thermal analysis (TG-DTA), scanning electron microscopy (SEM), energy dispersive spectroscopic analysis (EDX), and X-ray diffraction (XRD) techniques. The incorporation of GA would decrease the compressive strength of the mortar in the absence of GP. Incorporating both GA and GP could change the hydration environment, promote pozzolanic reaction of GP and improve the compressive strength. GP does not lead to but can effectively control ASR (Alkali Silica Reaction). GP and GA do not transform the type of hydrates, but have a great influence on the amounts of hydration products, and generate more calcium silicate hydrate (C-S-H gel) with lower Ca/Si ratio. GP and GA with good gradation will make the microstructure denser.

Similar content being viewed by others

References

Topc IB, Canbaz M. Properties of Concrete Containing Waste Glass[J]. Cement and Concrete Research, 2004, 34(2): 267–274

Shi CJ, Wu YH, Riefler C, et al. Characteristics and Pozzolanic Reactivity of Glass Powders[J]. Cement and Concrete Research, 2005, 35(5): 987–993

Zhang MJ, Zhao H. A Study on the Waste Glass Recycled as Building Materials[J]. Journal of Jingling Institute of Technology, 2011, 27(2): 51–56

Chidiac SE, Mihaljevic SN. Performance of Dry Cast Concrete Blocks Containing Waste Glass Powder or Polyethylene Aggregates[J]. Cement and Concrete Composites, 2011, 33(8): 855–863

Limbachiya M, Meddah MS, Fotiadou S. Performance of Granulated Foam Glass Concrete[J]. Construction and Building Materials, 2012, 28(1): 759–768

Liu SH, Xie GS, Wang S. Effect of Curing Temperature on Hydration Properties of Waste Glass Powder in Cement-Based Materials[J]. Journal of Thermal Analysis and Calorimetry, 2015, 19(1): 47–55

Idir R, Cyr M, Tagnit-Hamou A. Use of Fine Glass as ASR Inhibitor in Glass Aggregate Mortars[J]. Construction and Building Materials, 2010, 24(7): 1309–1312

Feng XX, Hu CG, Wang XY, et al. Effect of Al3+ on the Products of Alkali-Silica Reaction[J]. Journal of Wuhan University of Technology, 2009, 31(7): 131–133

Novotna M, Satava V, Maixner J, et al. Preparation and Characterization of Analcime Powders[J]. Journal of Optoelectronics and Advanced Materials, 2003, 26(5):1405–1409

Akei T, Ota H, Dong Q, et al. Preparation of Porous Material from Waste Bottle Glass by Hydrothermal Treatment[J]. Ceramics Internationa, 2012, 38(3): 2153–2157

Yuan RZ. Cementitious Material Science[M]. Wuhan: Wuhan University of Technology Press, 1996: 72–91

Tayly HFW. Cement Chemistry[M]. London: Thomas Telford Ltd, 1990: 113–115

Yang QB, Zhang SQ, Huang SY, et al. Effect of Ground Quartz Sand on Properties of High Strength Concrete in the Steam Autoclaved Curing[J]. Cement and Concrete Research, 2000, 30(12): 1993–1998

Li ZW, Xu JY, Bai E. Static and Dynamic Mechanical Properties of Concrete after High Temperature Exposure[J]. Materials Science and Engineering, 2012, 544(15): 27–32

Liu SH, Kong YN, Wang L. A Comparison of Hydration Properties of Cement-Low Quality Fly Ash Binder and Cement-Limestone Powder Binder[J]. Journal of Thermal Analysis and Calorimetry, 2014, 116 (2): 937–943

Liu SH, Xie GS, Rao MJ, Effect of Waste Glass Powder on Properties and Microstructure of Ultra-High Performance Cement Based Materials[J]. Materials Research Innovations, 2013, 17(s1): 210–214

Liu SH, Li LH. Influence of Fineness on the Cementitious Properties of Steel Slag[J]. Journal of Thermal Analysis and Calorimetry, 2014, 117(2): 629–634

Lian HZ, Tong L, Chen EY. Phase Research Foundation of Building Materials[M]. Beijing: Tsinghua University Press, 1995: 138–143

Lisa M, Federico EB. Waste Glass-A Supplementary Cementitious Material[D]. Open Access Dissertations and Theses, 2013: 75–82

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (51208391) and the National Basic Research Program of China (973 Program, 2013CB035901)

Rights and permissions

About this article

Cite this article

Liu, S., Wang, S., Zhou, W. et al. Strength and microstructure of mortar containing glass powder and/or glass aggregate. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 31, 1302–1310 (2016). https://doi.org/10.1007/s11595-016-1531-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-016-1531-4