Abstract

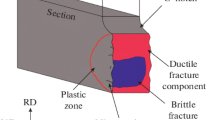

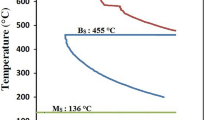

The impact toughness scattering in the ductile-brittle transition temperature (DBTT) region was experimentally examined on mixed and homogeneous grains of low alloy high strength bainitic steel under dynamic loading conditions. The results revealed that the mixed grain microstructure had larger impact toughness scattering than the homogeneous one, and the impact toughness scattering was mainly caused by the scattering in the cleavage fracture stress σ f. The value of σ f is related to the size of the microcrack formed in the bainitic packet. When a bainitic packet-sized microcrack propagates from one bainitic packet into the adjacent packet, cleavage fracture occurs. The cleavage fracture is controlled by the few coarse packets in the microstructures, and the σ f scattering is influenced by the varied distances/relative locations between these coarse packets, and homogenizing the distribution of fine bainitic packet sizes is an effective way to reduce the impact toughness scattering in the DBTT region.

Similar content being viewed by others

References

Sung H K, Shin S Y, Hwang B, et al. Effects of Carbon Equivalent and Cooling Rate on Tensile and Charpy Impact Properties of Highstrength Bainitic Steels[J]. Materials Science and Engineering A, 2011, 530: 530–538

Brnic J, Niu J, Turkalj G, et al. Behavior of HSLA a 709 Steel Under Different Environmental Conditions[J]. Journal of Wuhan University of Technology, 2010, 25(26): 897–902

Kang J S, Seol J B, Park CG. Three-dimensional Characterization of Bainitic Microstructures in Low-carbon High-strength Low-alloy Steel Studied by Electron Backscatter Diffraction[J]. Materials Characterization, 2013, 79(5): 110–121

Wallin K. The Scatter in KIC-results[J]. Engineering Fracture Mechanics, 1984, 19(6): 1085–1093

Haušild P, Berdin C, Bompard P. Prediction of Cleavage Fracture for a Low-alloy Steel in the Ductile-to-brittle Transition Temperature Range[J]. Materials Science and Engineering A, 2005, 391(1-2): 188–197

Zhang X Z, Knott J F. The Statistical Modeling of Brittle Fracture in Homogeneous and Heterogeneous Steel Microstructures[J]. Acta Materialia, 2000, 48(9): 2135–2146

Samal M K, Chakravartty J K, Seidenfuss M, et al. Evaluation of Fracture Toughness and Its Scatter in the DBTT Region of Different Types of Pressure Vessel Steels[J]. Engineering Failure Analysis, 2011, 18(1): 172–185

Böhme W, Bernauer G, Schmitt W. Scatter of a Ferritic Steel in the Transition Region Analyzed by Charpy Tests and Dynamic Tensile Tests[J]. Nuclear Engineering and Design, 188(2): 149-154

Chen J H, Wang G Z, Wang Z, et al. Further Study on the Scattering of the Local Fracture Stress and Allied Toughness value[J]. Metallurgical and Materials Transactions A, 1991, 22(10): 2287–2296

Strnadel B, Haušild P. Statistical Scatter in the Fracture Toughness and Charpy Impact Energy of Pearlitic Steel[J]. Materials Science and Engineering A, 2008, 486(1-2): 208

Chen J H, Cao R. Micromechanism of Cleavage Fracture of Metals[M]. London: Elsevier, 2014

Curry D A, Knott J F. Effect of Microstructure on Cleavage Fracture Toughness of Quenched and Tempered Steels[J]. Metal Science, 1979, 13: 341–345

Ritchie R O, Knott J F, Rice J R. On the Relationship between Critical Tensile Stress and Fracture Toughness in Mild Steel[J]. Journal of the Mechanics and Physics of Solids, 1973, 21(6): 395–410

Chen J H, Ma H, Wang G Z. Fracture Behavior of C-Mn Steel and Weld Metal in Notched and Precracked Specimens: Part I. Fracture Behavior[J]. Metallurgical and Materials Transactions A, 1990, 21(1): 313–320

Chen J H, Wang G Z, Yan C, et al. Advances in the Mechanism of Cleavage Fracture of Low Alloy Steel at Low Temperature. Part I: Critical Event[J]. International Journal of Fracture, 1997, 83(4): 105–120

Yu S R, Yan Z G, Cao R, et al. On the Change of Fracture Mechanism with Test Temperature[J]. Engineering Fracture Mechanics, 2006, 73(3): 331–347

Li Z, Tian Y, Kang S, et al. Effect of Fast Cooling Rate on the Microstructure and Mechanical Properties of Low-Carbon High-Strength Steel Annealed in the Intercritical Region[J]. Journal of Wuhan University of Technology, 2013, 29 (3): 572–577

Beremin F M. A Local Criterion for Cleavage Fracture of a Nuclear Pressure Vessel Steel[J]. Metallurgical and Materials Transactions A, 1983, 14(11): 2277–2287

Brückner A, Munz D. Prediction of Failure Probabilities for Cleavage Fracture from the Scatter of Crack Geometry and of Fracture Toughness Using the Weakest Link Model[J]. Engineering Fracture Mechanics, 1983, 18(2): 359–375

Khalili A, Kromp K. Statistical Properties of Weibull Estimators[J]. Journal of Materials Science, 1991, 26(24): 6741–6752

Cao R, Zhang X B, Wang Z, et al. Investigation of Microstructural Features Determining the Toughness of 980 MPa Bainitic Weld Metal[J]. Metallurgical and Materials Transactions A, 2014, 45(2): 815–834

Hwang B, Kim Y G, Lee S, et al. Effective Grain Size and Charpy Impact Properties of High-toughness X70 Pipeline Steels[J]. Metallurgical and Materials Transactions A, 2005, 36(8): 2107–2114

Rancel L, Gómez M, Medina S F, et al. Measurement of Bainite Packet Size and its Influence on Cleavage Fracture in a Medium Carbon Bainitic Steel[J]. Materials Science and Engineering A, 2011, 530: 21–27

Kim M C, Oh Y J, Hong J H. Characterization of Boundaries and Determination of Effective Grain Size in Mn-Mo-Ni Low Alloy Steel from the View of Misorientation[J]. Scripta Materialia, 2000, 43(3): 205–211

Bowen P, Druce S G, Knott J F. Effects of Microstructure on Cleavage Fracture in Pressure Vessel Steel[J]. Acta Metallurgica, 1986, 34(6): 1121–1131

Hahn G T. The Influence of Microstructure on Brittle Fracture Toughness[J]. Metallurgical and Materials Transactions A, 1984, 15(6): 947–959

Lin T, Evans AG, Ritchie RO. Stochastic Modeling of the Independent Roles of Particle Size and Grain Size in Transgranular Cleavage Fracture[J]. Metallurgical and Materials Transactions A, 1987, 18(5): 641–651

Author information

Authors and Affiliations

Corresponding author

Additional information

Sponsored by the National Basic Research Program of China (No. 2011CB610405), the Reactor Material Development Research Project of Shanghai Baoshan Iron & Steel Research Institute (No. X08ECEJ190)

Rights and permissions

About this article

Cite this article

Shi, K., Chen, J., Hou, H. et al. Impact toughness scattering of bainitic steel in the ductile-brittle transition temperature region. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 31, 636–643 (2016). https://doi.org/10.1007/s11595-016-1422-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-016-1422-8