Abstract

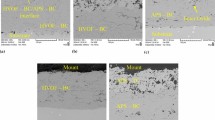

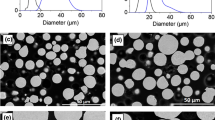

High temperature oxidation behavior of the bond coat layer is a critical factor that controls the failure mechanism of thermal barrier coatings (TBCs). Previous work reveald that TBCs with cryomilled NiCrAlY bond coats exhibited an improved oxidation behavior compared to equivalent TBCs with conventional bond coats. The cryomilled NiCrAlY bond coats contributed to a slower growth rate of thermally grown oxides (TGO) with a final thinner thickness and enhanced homogeneity in TGO composition. To better understand the improved oxidation behavior, a mechanistic investigation based on diffusion theory and quantum mechanics is performed to elucidate the role of aluminum diffusion in the oxidation behavior and how the microstructural features of the cryomilled NiCrAlY bond coats, i e, the creation of a thermally stable, uniform distribution of ultrafine Al-rich oxide dispersoids, affect the diffusion kinetics of Al and the migration of free electrons. It is revealed that these Al-rich oxide dispersoids result in a uniform diffusion of Al and slow migration of free electrons within the NiCrAlY bond coat, consequently leading to the improved oxidation behavior.

Similar content being viewed by others

References

Padture NP, Gell M, Jordan EH. Thermal Barrier Coatings for Gas-Turbine Engine Applications[J]. Science, 2002 (296): 280–289

Clarke DR, Levi CG. Materials Design for the Next Generation Thermal Barrier Coatings[J]. Annual Review of Materials Research, 2003(33): 383–389

Nicholls JR, Simms NJ, Chan WY, et al. Smart Overlay Coatings -Concept and Practice[J]. Surface and Coatings Technology, 2002 (149): 236–240

Miller RA. Current Status of Thermal Barrier Coatings -an Overview[J]. Surface and Coatings Technology, 1987 (30): 1–8

Evans AG, Mumm DR, Hutchinson JW, et al. Mechanisms Controlling the Durability of Thermal Barrier Coatings[J]. Progress in Materials Science, 2001, 46: 505–510

Sivakumar R, Mordike BL. High Temperature Coatings for Gas Turbine Blades: A Review[J]. Surface and Coatings Technology, 1989(37): 139–143

Taylor TA. Low Thermal Expansion Bondcoats for Thermal Barrier Coatings[P]. United States, US 7910225, 2011

Ma K, Schoenung JM. Influence of Cryomilling on the Microstructural Features in HVOF-sprayed NiCrAlY Bond Coats for Thermal Barrier Coatings: Creation of a Homogeneous Distribution of Nano-scale Dispersoids[J]. Philosophical Magazine Letters, 2010(90): 739–745

Achar DRG, Munoz-Arroyo R, Singheiser L, et al. Modelling of Phase Equilibria in MCrAlY Coating Systems[J]. Surface and Coatings Technology, 2004(187): 272–276

Nijdam TJ, Sloof WG. Microstructural Evolution of a Mcraly Coating Upon Isothermal Annealing[J]. Materials Characterization, 2008(59): 1 697–1 702

Ma K, Tang F, Schoenung JM. Investigation Into the Effects of Fe Additions on the Equilibrium Phase Compositions, Phase Fractions and Phase Stabilities in The Ni-Cr-Al System[J]. Acta Materialia, 2010(58): 1 518–1 523

Brandl W, Grabke HJ, Toma D, et al. The Oxidation Behaviour of Sprayed Mcraly Coatings[J]. Surface and Coatings Technology, 1996, 41: 86–87

Ajdelsztajn L, Picas JA, Kim GE, et al. Oxidation Behavior of HVOF Sprayed Nanocrystalline NiCrAlY Powder[J]. Materials Science and Engineering A, 2002(338): 33–37

Clarke DR, Phillpot SR. Thermal Barrier Coating Materials[J]. Materials Today, 2005(8): 22–28

Hou PY. Impurity Effects on Alumina Scale Growth[J]. Journal of the American Ceramic Society, 2003(86): 660–667

Evans HE, Taylor MP. Diffusion Cells and Chemical Failure of MCrAlY Bond Coats in Thermal-Barrier Coating Systems[J]. Oxidation of Metals, 2001(55): 17–23

Niranatlumpong P, Ponton CB, Evans HE. The Failure of Protective Oxides on Plasma-Sprayed NiCrAlY Overlay Coatings[J]. Oxidation of Metals, 2000(53): 241–243

Evans AG, Clarke DR, Levi CG. The Influence of Oxides on the Performance of Advanced Gas Turbines[J]. Journal of the European Ceramic Society, 2008(28): 1 405–1 409

Rabiei A, Evans AG. Failure Mechanisms Associated with the Thermally Grown Oxide in Plasma-Sprayed Thermal Barrier Coatings[J]. Acta Materialia, 2000(48): 3 963–3 968

Xu T, Faulhaber S, Mercer C, et al. Observations and Analyses of Failure Mechanisms in Thermal Barrier Systems with Two Phase Bond Coats Based on Nicocraly[J]. Acta Materialia, 2004(52): 1 439–1 445

Ajdelsztajn L, Tang F, Kim GE, et al. Synthesis and Oxidation Behavior of Nanocrystalline Mcraly Bond Coatings[J]. Journal of Thermal Spray Technology, 2005(14): 23–32

Echsler H, Shemet V, Schütze M, et al. Cracking In and Around The Thermally Grown Oxide in Thermal Barrier Coatings: A Comparison of Isothermal and Cyclic Oxidation[J]. Journal of Materials Science, 2006(41): 1 047–1 452

Pomeroy MJ. Coatings for Gas Turbine Materials and Long Term Stability Issues[J]. Materials & Design, 2005(26): 223–226

Wu YN, Qin M, Feng ZC, et al. Improved Oxidation Resistance of Nicraly Coatings[J]. Materials Letters, 2003( 57): 2 404-2 408

Okada M, Vassen R, Karger M, et al. Deposition and Oxidation of Oxide-Dispersed CoNiCrAlY Bondcoats[J]. Journal of Thermal Spray Technology, 2014( 23): 147–152

Czech N, Schmitz F, Stamm W. Improvement of Mcraly Coatings by Addition of Rhenium[J]. Surface and Coatings Technology, 1994, 68-69: 17–20

Huang L, Sun XF, Guan HR, et al. Improvement of The Oxidation Resistance of Nicraly Coatings by the Addition of Rhenium[J]. Surface and Coatings Technology, 2006( 201): 1 421–1 430

Beele W, Czech N, Quadakkers WJ, et al. Long-Term Oxidation Tests on a Re-Containing Mcraly Coating[J]. Surface and Coatings Technology, 1997, 94-95: 41–47

Chen SF, Liu SY, Wang Y, et al. Microstructure and Properties of HVOF-Sprayed NiCrAlY Coatings Modified by Rare Earth[J]. Journal of Thermal Spray Technology, 2014( 23): 809–813

Ma K, Schoenung JM. Isothermal Oxidation Behavior of Cryomilled Nicraly Bond Coat: Homogeneity and Growth Rate of TGO[J]. Surface and Coatings Technology, 2011( 205): 5 178–5 183

Tang F, Ajdelsztajn L, Kim GE, et al. Effects Of Variations In Coating Materials And Process Conditions on the Thermal Cycle Properties Of Nicraly/Ysz Thermal Barrier Coatings[J]. Materials Science and Engineering: A, 2006(425): 94–98

Denis A, Garcia EA. Model to Simulate Parabolic Followed by Linear Oxidation Kinetics[J]. Oxidation of Metals, 1988(29): 153–158

Birks N, Meier G. Introduction to High Temperature Oxidation of Metals[M]. London: Arnold, 1993

Hindam HM, Smeltzer WW. Application of Auger Electron Spectroscopy and Inert Metal Marker Techniques to Determine Metal and Oxygen Transport in Oxide Films on Metals[J]. Oxidation of Metals, 1980( 14): 337

Toma D, Brandl W, Köster U. The Characteristics of Alumina Scales Formed on HVOF-Sprayed MCrAlY Coatings[J]. Oxidation of Metals, 2000( 53): 125–132

Brandl W, Toma D, Krüger J, et al. The Oxidation Behaviour of HVOF Thermal-Sprayed Mcraly Coatings[J]. Surface and Coatings Technology, 1997, 94-95: 21–27

Toscano J, Vaen R, Gil A, et al. Parameters Affecting TGO Growth and Adherence on Mcraly-Bond Coats for TBC's[J]. Surface and Coatings Technology, 2006(201): 3 906-3 910

Tang F, Ajdelsztajn L, Schoenung JM. Influence of Cryomilling on the Morphology and Composition of the Oxide Scales Formed on HVOF Conicraly Coatings[J]. Oxidation of Metals, 2004( 61): 219–223

Pauling L. The Nature of The Chemical Bond. IV. The Energy of Single Bonds and The Realtive Electronegativity of Atoms[J]. Journal of the American Chemical Society, 1932( 54): 3 570–3 673

Hastelloy X Alloy Report[OL]. Http://www.haynesintl.com/pdf/h3009. pdf, 1997

Schiff LI. Quantum Mechanics[M]. New York: McGraw-Hill, 1968:46

Griffiths DJ. Introduction to Quantum Mechanics[M]. 2nd ed. NJ: Prentice Hall, 2004

Giuseppe Grosso, Parravicini GP. Solid State Physics[M]. New York: Academic Press, 2000

Carl M Bender, SA Orszag. Advanced Mathematical Methods for Scientists and Engineers[M]. Berlin: Springer, 1999

WKB approximation. http://en.wikipedia.org/wiki/WKB_approximation[OL].

Tang F, Ajdelsztajn L, Schoenung JM. Characterization of Oxide Scales Formed on HVOF Nicraly Coatings with Various Oxygen Contents Introduced During Thermal Spraying[J]. Scripta Materialia, 2004(51): 25–29

Jackson JD. Classical Electrodynamics[M]. 3rd ed, New York: Wiley 1998

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the U.S. Office of Naval Research (ONR) (No. N00014-06-1-0506)

Rights and permissions

About this article

Cite this article

Ma, K., Tang, X. & Schoenung, J.M. Mechanistic investigation into the role of aluminum diffusion in the oxidation behavior of cryomilled NiCrAlY bond coat. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 31, 35–43 (2016). https://doi.org/10.1007/s11595-016-1326-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-016-1326-7