Abstract

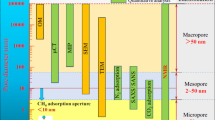

We prepared concretes (RC0, RC30, and RC100) with three different mixes. The poresize distribution parameters of RAC were examined by high-precision mercury intrusion method (MIM) and nuclear magnetic resonance (NMR) imaging. A capillary-bundle physical model with random-distribution pores (improved model, IM) was established according to the parameters, and dry-shrinkage strain values were calculated and verified. Results show that in all pore types, capillary pores, and gel pores have the greatest impacts on concrete shrinkage, especially for pores 2.5-50 and 50-100 nm in size. The median radii are 34.2, 31, and 34 nm for RC0, RC30, and RC100, respectively. Moreover, the internal micropore size distribution of RC0 differs from that of RC30 and RC100, and the pore descriptions of MIM and NMR are consistent both in theory and in practice. Compared with the traditional capillary-bundle model, the calculated results of IM have higher accuracy as demonstrated by experimental verification.

Similar content being viewed by others

References

Zhang MH, LI Hui. Pore Structure and Chloride Permeability of Concrete Containing Nano-particles for Pavement [J]. Construction and Building Materials, 2011, 25(2): 608–616

Bazant ZP, Wittmann FH. Creep and Shrinkage in Concrete Structures [M]. A Wiley-Interscience publ., 1982, 363: 17

Shimomura T, Maekawa K. Anaysis of the Drying Shrinkage Behavior of Concrete Using a Micromechanical Model based on the Microscopre Structure of Concrete[J]. Magazine of Concrete Research, 1997, 49(181): 303–322

Xing F, Dong BQ, Li ZJ. The study of Pore Structure and Its Influence on Material Properties of Cement-based Piezoelectric Ceramic Composites[J]. Construction and Building Materials, 2009, 23(3): 1374–1377

Hasaba S, Kawamure M. Drying Shrinkage and Durability of the Concrete Made of Recycled Concrete Aggregate [J]. Trans. of the Japan Concrete Institute, 1981, (3):55

Katz A. Properties of Concrete Made with Recycled Aggregate from Partially Hydrated Old Concrete[J]. Cement and Concrete Research, 2003, 33(5): 703–711

Debieb F, Kenai S. The Use of Coarse and Fine Crushed Bricks as Aggregate in Concrete [J]. Construction and Building Materials, 2008, 22(5): 886–893

Courard L, Michel F, Delhez P. Use of Concrete Road Recycled Aggregates for Roller Compacted Concrete[J]. Construction and Building Materials, 2010, 24(3): 1–6

Domingo-Cabo A, Lázaro C, López-Gayarre F. Creep and Shrink Age of Recycled Aggregate Concrete[J]. Construction and Building Materials, 2009, (3): 545–553

Evangelista L, Brito J. Durability Performance of Concrete Made with Fine Recycled Concrete Aggregates[J]. Cement and Concrete Composites, 2010, 32(1): 9–14

He YD, Mao ZQ, Xiao LZ, et al. An Improved Method of Using NMR T 2 Distribution to Evaluate Pore Size Distribution[J]. Chinese Journal of Geophysics, 2005, 48(2): 373–378

Li TJ, Li ZF, Zhao YC, et al. Research on Pore-structure Consistency of NMR and Mercury Intrusion[J]. Natural Gas Industry, 2006, 26(10): 57–59

Wu ZW. Expansive Concrete[M]. China Railway Publishing House, 1990, 248:17–18

Huang GX, Hui RY. Shrinkage of Concrete[M]. China Railway Publishing House, 1990, 142: 11

Wu ZW. Shrinkage-compensating Concrete[M]. China Architecture & Building Press, 1979, 84: 8–10

Zhang YC, Zhang YF, Zhang YB. Finite Element Simulation based on Microscopic Mechanism of Concrete Shrinkage Deformation[J]. Journal of Pingdingshan Institute of Technology, 2008, 17(5): 13–15

Xia Y Z. Finite Element Simulation of Micro-concrete Shrinkage Deformation[J]. Subgrade Engineering, 2009(6): 150–151

Chen Y. Preparation and Characterization of Porous Materials[M]. Publishing House of University of Science and Technology of China, 2010, 272:12–17

Huang GX, Hui RY. Shrinkage of Concrete[M]. China Railway Publishing House, 1990, 142: 17–19

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (51202304), the China Postdoctoral Science Foundation (2014M552320) and Scientific, the Technological Talents’ Special Funds of Wanzhou District and Scientific and Technological Research Program of Chongqing Municipal Education Commission (KJ1401016) and the Youth Project of Chongqing Three Gorges College (13QN-20)

Rights and permissions

About this article

Cite this article

Guo, Y., Wang, X. & Qian, J. Physical model of drying shrinkage of recycled aggregate concrete. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 30, 1260–1267 (2015). https://doi.org/10.1007/s11595-015-1305-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-015-1305-4