Abstract

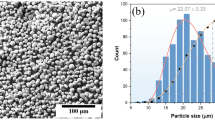

The fabrication of high volume fraction (HVF) M7C3 (M=Cr, Fe) reinforced Fe-based composite coating on ASTM A36 steel plate using plasma transferred arc (PTA) welding was studied. The results showed that the volume fraction of carbide M7C3 was more than sixty percent, and the relative wear resistance of the coating tested on a block-on-ring dry sliding tester at constant load (100 N) and variable loads (from 100 to 300 N) respectively was about 9 and 14 times higher than that of non-reinforced α-Fe coating. In addition, under constant load condition the friction coefficients (FCs) of two coatings increased first and then decreased with increasing sliding distance. However, under variable loads condition the FCs of non-reinforced α-Fe based coating increased gradually, while that of HVF M7C3 reinforced coating decreased as the load exceeded 220 N. The worn surface of non-reinforced α-Fe based coating was easily deformed and grooved, while that of the HVF M7C3 reinforced coating was difficult to be deformed and grooved.

Similar content being viewed by others

References

Y H Qu, J D Xing, X H Zhi, et al. Effect of Cerium on the As-cast Microstructure of a Hypereutectic High Chromium Cast Iron[J]. Mater. Lett., 2008, 62(17-18): 3 024–3 027

A Zikin, I Hussainova, C Katsich, et al. Advanced Chromium Carbidebased Hardfacings[J]. Surf. Coat. Technol., 2012, 206(19–20): 4 270–4 278

D W Zhang, X P Zhang. Laser Cladding of Stainless Steel with Ni-Cr3C2 and Ni-WC for Improving Erosive-corrosive Wear Performance[J]. Surf. Coat. Technol., 2005, 190(2–3): 212–217

J Mateos, J M Cuetos, R Vijande, et al. Tribological Properties of Plasma Sprayed and Laser Remelted 75/25 Cr3C2/NiCr Coatings[J]. Tribol. Int., 2001, 34(5): 345–351

Y F Liu, Z Y Xia, J M Han, et al. Microstructure and Wear Behavior of (Cr,Fe)7C3 Reinforced Composite Coating Produced by Plasma Transferred Arc Weld-surfacing Process[J]. Surf. Coat. Technol., 2006, 201(3–4): 863–867

J Wang, B D Sun, Q X Guo, et al. Wear Resistance of a Cr3C2-NiCr Detonation Spray Coating[J]. J. Therm. Spray Technol., 2002, 11(2): 261–265

G C Ji, C J Li, Y Y Wang, et al. Microstructural Characterization and Abrasive Wear Performance of HVOF Sprayed Cr3C2-NiCr Coating[J]. Surf. Coat. Technol., 2006, 200(24): 6 749–6 757

X Y Sheng, S Y Yu. Performance in Resistance to Surface Fatigue for Cr3C2-25% NiCr Coatings by Plasma Spray and CDS Spray[J]. Tribol. Lett., 2004, 16(3): 173–180

L Z Du, C B Huang, W G Zhang, et al. Preparation and Wear Performance of NiCr/Cr3C2-NiCr/hBN Plasma Sprayed Composite Coating[J]. Surf. Coat. Technol., 2011, 205(12): 3 722–3 728

G F Sun, Y K Zhang, C S Liu, et al. Microstructure and Wear Resistance Enhancement of Cast Steel Rolls by Laser Surface Alloying NiCr-Cr3C2[J]. Mater. Des., 2010, 31(6): 2 737–2 744

J C Betts. The Direct Laser Deposition of AISI316 Stainless Steel and Cr3C2 Powder[J]. J. Mater. Process. Technol., 2009, 209(11): 5 229–5 238

D W Zhang, T C Lei, F J Li. Laser Cladding of Stainless Steel with Ni-Cr3C2 for Improved Wear Performance[J]. Wear, 2001, 251: 1 372–1 376

C G Pan, H C Wang, H F Wang, et al. Microstructure and Thermal Physical Parameters of Ni60-Cr3C2 Composite Coating by Laser Cladding[J]. J. Wuhan Univ. Technol., 2010, 25(6): 991–995

D W Zhang, T C Lei. The Microstructure and Erosive-corrosive Wear Performance of Laser-clad Ni-Cr3C2 Composite Coating[J]. Wear, 2003, 255: 129–133

M S Yang, X B Liu, J W Fan, et al. Microstructure and Wear Behaviors of Laser Clad NiCr/Cr3C2-WS2 High Temperature Self-lubricating Wear-resistant Composite Coating[J]. Appl. Surf. Sci., 2012, 258(8):3 757–3 762

J Wang, B Sun, Q X Guo, et al. Wear Resistance of a Cr3C2-NiCr Detonation Spray Coating[J]. J. Therm. Spray Technol., 2002, 11(2): 261–265

Z Marcano, J Lesage, D Chicot, et al. Microstructure and Adhesion of Cr3C2-NiCr Vacuum Plasma Sprayed Coatings[J]. Surf. Coat. Technol., 2008, 202(18): 4 406–4 410

D J Branagan, M C Marshall, B E Meacham. High Toughness High Hardness Iron Based PTAW Weld Materials[J]. Mater. Sci. Eng., A, 2006, 428(1–2): 116–123

A S C M D’Oliveira, J J Tigrinho, R R Takeyama. Coatings Enrichment by Carbide Dissolution[J]. Surf. Coat. Technol., 2008;202(19): 4 660–4 665

R L Deuis, J M Yellup, C Subramanian. Metal-matrix Composite Coatings by PTA Surfacing[J]. Compos. Sci. Technol., 1998;58(2): 299–309

C Katsich, E Badisch. Effect of Carbide Degradation in a Nibased Hardfacing Under Abrasive and Combined Impact/Abrasive Conditions[J]. Surf. Coat. Technol., 2011, 206(6): 1 062–1 068

S F Zhou, X Y Zeng. Growth Characteristics and Mechanism of Carbides Precipitated in WC-Fe Composite Coatings by Laser Induction Hybrid rapid Cladding[J]. J. Alloys Compd., 2010, 505(2): 685–691

G Z Ma, B S Xu, H D Wang, et al. Effect of Surface Nanocrystallization on the Tribological Properties of 1Cr18Ni9Ti Stainless Steel[J]. Mater. Lett., 2011, 65(9): 1 268–1 271

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Fundation of China (No.51171116), the Ministry of Science and Technology of China (No.2009DFB50350), the Research Foundation of Education Bureau of Hubei Province, China (No.Q20122304), and the Foundation of Hubei University of Automotive Technology, China (No.BK201205)

Rights and permissions

About this article

Cite this article

Yuan, Y., Li, Z. Microstructure and wear performance of high volume fraction carbide M7C3 reinforced Fe-based composite coating fabricated by plasma transferred arc welding. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 29, 1028–1035 (2014). https://doi.org/10.1007/s11595-014-1038-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-014-1038-9