Abstract

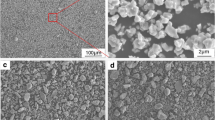

Ti-based composite coatings reinforced by in situ synthesized TiB and TiC were deposited on Ti6Al4V substrates by laser cladding. The effects of Y2O3 on the microstructure and cracking susceptibility of the coatings were investigated in details. It is shown that a small amount of Y2O3 addition can significantly refine the microstructure of the coatings by hastening spheroidization of the primary phase structure. The maximum refinement in microstructure was obtained with the optimum (2 wt%) addition of Y2O3. Moreover, it can increase the volume fraction of TiC and reduce the residual stress of the coatings due to the decrease in lattice distortion of the α(Ti) matrix. All of these factors lead to the reduction in cracking susceptibility of the coatings containing Y2O3 on the premise that the hardness of the coatings is improved. The fracture toughness of the coatings without and with Y2O3 (2 wt%) is 8.32 and 17.36 MPa·m1/2, respectively. Scanning electron microscope examination reveals a transition of the fractured surfaces from cleavage fracture to quasi-cleavage fracture resulting from the Y2O3 addition.

Similar content being viewed by others

References

A Suarez, J M Amado, M J Tobar, et al. Study of Residual Stresses Generated inside Laser Cladded Plates Using FEM and Diffraction of Synchrotron Radiation [J]. Surf. Coat. Technol., 2010, 204:1 983–1 988

J J Candel, V Amigo, J A Ramos, et al. Sliding Wear Resistance of TiCp Reinforced Titanium Composite Coating Produced by Laser Cladding [J]. Surf. Coat. Technol., 2010, 204: 3 161–3 166

J D Majumdar, L Li. Development of Titanium Boride (TiB) Dispersed Titanium (Ti) Matrix Composite by Direct Laser Cladding [J]. Mater. Lett., 2010, 64: 1 010–1 012

Y L Yang, D Zhang, W Yan, et al. Microstructure and Wear Properties of TiCN/Ti Coatings on Titanium Alloy by Laser Cladding [J]. Opt. Laser Eng., 2010, 48: 119–124

J Nurminen, J Nakki, P Vuoristo. Microstructure and Properties of Hard and Wear Resistant MMC Coatings Deposited by Laser Cladding [J]. Int. J. Refract. Met. H., 2009, 27: 472–478

J Li, Z S Yu, H P Wang, et al. Microstructural Evolution of in situ Synthesized TiB and TiC Reinforced Titanium Matrix Composites Coatings on Ti6Al4V by Laser Cladding [J]. Int. J. Min. Met. Mater., 2010, 17: 481–488

Y J Huang, X Y Zeng, Q W Hua, et al. Microstructure and Interface Interaction in Laser Induction Hybrid Cladding of Ni-based Coating [J]. Appl. Surf. Sci., 2009, 255: 3 940–3 945

H Zhang, Y Shi, M Kutsuna, et al. Laser Cladding of CoImonoy 6 Powder on AISI316L Austenitic Stainless Steel [J]. Nucl. Eng. Des., 2010, 240: 2 691–2 696

V Fallah, M Alimardani, S F Corbin, et al. Impact of Localized Surface Preheating on the Microstructure and Crack Formation in Laser Direct Deposition of Stellite 1 on AISI 4340 Steel [J]. Appl. Surf. Sci., 2010, 257: 1 716–1 723

G Xu, M Kutsuna, Z Liu, et al. Characteristics of Ni-based Coating Layer Formed by Laser and Plasma Cladding Processes [J]. Mater. Sci. Eng. A, 2006, 417: 63–72

Y J Huang, X Y Zeng. Investigation on Cracking Behavior of Ni-based Coating by Laser-Induction Hybrid Cladding [J]. Appl. Surf. Sci., 2010, 256: 5 985–5 992

X H Wang, M Zhang, S Y Qu. Development and Characterization of (Ti, Mo)C Carbides Reinforced Fe-based Surface Composite Coating Produced by Laser Cladding [J]. Opt. Laser Eng., 2010, 48:893–898

D S Wang, E J Liang, M J Chao, et al. Investigation on the Microstructure and Cracking Susceptibility of Laser-Clad V2O5/NiCrBSiC Alloy Coatings [J]. Surf. Coat. Tech., 2008, 202:1 371–1 378

W L Song, Y A J Echigo, B D Zhu, et al. Effects of Co on the Cracking Susceptibility and the Microstructure of Fe-Cr-Ni Laser-Clad Layer [J]. Surf. Coat. Tech., 2001, 138: 291–295

M Alhammad, S Esmaeili, E Toyserkani. Surface Modification of Ti-6Al-4V Alloy Using Laser-Assisted Deposition of a Ti-Si Compound [J]. Surf. Coat. Tech., 2008, 203: 1–8

M J Chao, E J Liang. Effect of TiO2-doping on the Microstructure and the Wear Properties of Laser-Clad Nickel-based Coatings [J]. Surf. Coat. Tech., 2004, 179: 265–271

X B Liu, R L Yu. Effects of La2O3 on Microstructure and Wear Properties of Laser Clad γ/Cr7C3/TiC Composite Coatings on TiAl Intermatallic Alloy [J]. Mater. Chem. Phys., 2007, 101: 448–454

C F Wu, M X Ma, W J Liu, et al. Laser Cladding in-situ Carbide Particle Reinforced Fe-based Composite Coatings with Rare Earth Oxide Addition [J]. J. Rare Earth, 2009, 27: 997–1 002

K L Wang, Q B Zhang, M L Sun, et al. Rare Earth Elements Modification of Laser-Clad Nickel-based Alloy Coatings [J]. Appl. Surf. Sci., 2001, 174: 191–200

K L Wang, Q B Zhang, M L Sun, et al. Microstructural Characteristics of Laser Clad Coatings with Rare Earth Metal Elements [J]. J. Mater. Process. Technol., 2003, 139: 448–452

Z Y Zhang, X C Lu, B L Han, et al. Rare Earth Effect on Microstructure, Mechanical and Tribological Properties of CoCrW Coatings [J]. Mater. Sci. Eng. A, 2007, 444: 92–98

M X Li, S H Zhang, H S Li, et al. Effect of Nano-CeO2 on Cobalt-based Alloy Laser Coatings [J]. J. Mater. Process. Technol., 2008, 202:107–111

M X Li, Y Z He, X M Yuan. Effect of Nano-Y2O3 on Microstructure of Laser Cladding Cobalt-based Alloy Ccoatings [J]. Appl. Surf. Sci., 2006, 225: 2 882–2 887

Y R Liu, T E Fischer, A Dent. Comparison of HVOF and Plasma-Sprayed Alumina/Titanium Coatings [J]. Surf. Coat. Tech., 2003, 167: 68–76

T Zhao, X Cai, S X Wang, et al. Effect of CeO2 on Microstructure and Corrosive Wear Behavior of Laser-Cladded Ni/WC Coating [J]. Thin Solid Films, 2000, 379: 128–132

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the the National Natural Science Foundation of China (No.51002093) and “Shu Guang” Project of Shanghai Municipal Education Commission and Shanghai Education Development Foundation (No.12SG44)

Rights and permissions

About this article

Cite this article

Li, J., Li, G. & Luo, X. Effect of Y2O3 on cracking susceptibility of laser-clad Ti-based composites coatings. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 29, 1011–1018 (2014). https://doi.org/10.1007/s11595-014-1035-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-014-1035-z