Abstract

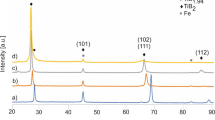

Ni-Ag/TiC composite coating was prepared on the 45 steel substrates by means of laser cladding. Microstructure and wear properties of composite coatings were analyzed using optical microscopy, field emission scanning electron microscopy and wear machine. The experimental results show that defects, such as cracks and pores, do not occur in the laser-cladded Ni-Ag/TiC composite coating and 45 steel substrate, and they present good metallurgical bonding between them. Compared with Ni/TiC composite coating, microhardness values of the two coatings do not present evident differences. The wear experiment result shows that Ni-Ag/TiC composite coated with Ag possesses low friction coefficient and good wear resistance compared with Ni/TiC composite coating.

Similar content being viewed by others

References

Zhang YP, Zhou ZR, Cheng JM, et al. Laser Remelting of NiCoCrA1Y Clad Coating on Superalloy[J]. Surface and Coatings Technology, 1996, 79: 131–134

ZHANG DW, LEI T. The Microstructure and Erosive-corrosive Wear Performance of Laser-clad Ni-Cr3C2 Composite Coating [J]. Wear, 2003, 255: 129–133

Anandkumar R, Almeida A, Colaço R, et al. Microstructure and Wear Studies of Laser Clad Al-Si/SiC(p) Composite Coatings [J]. Surface and Coatings Technology, 2007, 201: 9 497–9 505

Chen H, Pan CX. Microstructure and Fractural Morphology of Cobaltbased Alloy Laser Cladding [J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2003, 18(3): 30–32

Chen Y, Wang HM. Microstructure and Wear Resistance of a Laser Clad TiC Reinforced Nickel Aluminides Matrix Composite Coating [J]. Materials Science and Engineering A, 2004, 368: 80–87

Huang C, Zhang YZ, Vilar R. Microstructure and Anti-oxidation Behavior of Laser Clad Ni-20Cr Coating on Molybdenum Surface [J]. Surface and Coatings Technology, 2010, 205: 835–840

Wang SH, Chen JY, Xue L. A study of the Abrasive Wear Behaviour of Laser-clad Tool Steel Coatings [J]. Surface and Coatings Technology, 2006, 200: 3 446–3 458

Lu XD, Wang HM. High-temperature Sliding Wear Behaviors of Laser Clad Mo2Ni3Si/NiSi Metal Silicide Composite Coatings [J]. Applied Surface Science, 2003, 214: 190–195

Masanta M, Shariff SM, Choudhury AR. A Comparative Study of the Tribological Performances of Laser Clad TiB2-TiC-Al2O3 Composite Coatings on AISI 1020 and AISI 304 Substrates[J]. Wear, 2011, 271:1 124–1 133

Serres N, Portha N, Machi F. Influence of Salt Fog Aging Tests on Mechanical Resistance of Laser Clad-coatings[J]. Surface and Coatings Technology, 2011, 205: 5 330–5 337

Anandkumar R, Almeida A, Vilar R. Microstructure and Sliding Wear Resistance of an Al-12wt% Si/TiC Laser Clad Coating [J]. Wear, 2012, 282–283: 31–39

Xu J, Liu WJ, Zhong ML. Microstructure and Dry Sliding Wear Behavior of MoS2/TiC/Ni Composite Coatings Prepared by Laser Cladding [J]. Surface and Coatings Technology, 2006, 200: 4 227–4 232

Liu XB, Shi SH, Guo J, et al. Microstructure and Wear Behavior of γ/Al4C3/TiC/CaF2 Composite Coating on γ-TiAl Intermetallic Alloy Prepared by Nd: YAG Laser Cladding [J]. Applied Surface Science, 2009, 255: 5 662–5 668

Yang MS, Liu XB, Fan JW, et al. Microstructure and Wear Behaviors of Laser Clad NiCr/Cr3C2-WS2 High Temperature Self-lubricating Wear-resistant Composite Coating [J]. Applied Surface Science, 2012, 258: 3 757–3 762

Wang HM, Yu YL, Li SQ. Microstructure and Tribological Properties of Laser Clad CaF2/Al2O3 Self-lubrication Wear-resistant Ceramic Matrix Composite Coatings [J]. Scripta Materialia, 2002, 47: 57–61

Wang AH, Zhang XL, Zhang XF, et al. Ni-based Alloy/Submicron WS2 Self-lubricating Composite Coating Synthesized by Nd: YAG Laser Cladding[J]. Materials Science and Engineering A, 2008, 475: 312–318

Zhang XF, Wang AH, Zhang XL, et al. Microstructure and Tribological Properties of Laser Cladding Ni45-CaF2-WS2 Self-lubrication Coating [J]. Chinese Journal of Nonferrous Metals, 2008, 18: 215–220

Zhang XL, Zhang XF, Wang AH, et al. Microstructure of Metalbased Solid Self-lubrication Coating by Laser Cladding [J]. China Mechanical Engineering, 2006, 17: 2 084–2 088

CheZY n, Xu J, Liu WJ, et al. Study on Microstructure and Wear Behaviors of MoS2/TiC/Ni Composite Wear-resistant Coating by Laser Cladding [J]. Transactions of Materials and Heat Treatment, 2007, 28(S1): 254–258

Yang JX, Liu FL, Miao XH, et al. Microstructure and Tribology Characteristics of TC4/Ni/MoS2 Self-lubrication Coatings Prepared by Laser Cladding [J]. Heat Treatment of Metals, 2011, 36(8): 93–96

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Natural Science Foundation of Zhejiang Province (LY12E02003), the National Natural Science Foundation of China (No.51204064) and the Training Program of the Major Research Plan of the National Natural Science Foundation of China (No.91023030)

Rights and permissions

About this article

Cite this article

Zhu, L., Luo, L., Wu, Y. et al. Microstructure and tribological properties of laser clad Ni-Ag/Tic composite coating. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 29, 242–245 (2014). https://doi.org/10.1007/s11595-014-0901-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-014-0901-z