Abstract

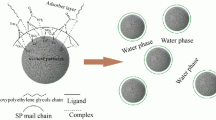

A macromer, methoxypolyethylene glycol acrylate (MPEGAA), was synthesized by direct esterification using methoxypolyethylene glycol (MPEG-1200) and acrylic acid (AA) as the main materials. MPEGAA was then used to prepare a polyacrylic acid superplasticizer modified with 2-acrylamido-2-methylpropane sulfonic acid (AMPS). A single-factor test was performed to investigate the effects of the molar ratio of acid to alcohol (n(AA)/n(MPEG)), inhibitor amount, catalyst amount, temperature, and time of esterification on the synthesis of MPEGAA. The experimental results showed that the optimal esterification conditions were as follows: n(AA)/n(MPEG), 3.5:1; amount of hydroquinone (as an inhibitor), 1.2%; amount of para-toluenesulfonic acid (as a catalyst), 5.5%; reaction temperature, 95 °C; and reaction time, 6 h. The AMPS-modified polyacrylic acid superplasticizer prepared under the optimal esterification conditions enabled the achievement and maintenance of high cement dispersibility. At an admixture amount of 0.15%, the cement paste fluidity was initially as high as 300 mm, and then decreased to 315 mm after 1 h and to 290 mm after 2 h.

Similar content being viewed by others

References

Xu ZN, Xiao GM, Zhou JN. Kinetics of Carboxylic Acid Terpolymer High Performance Water-reducing Agent[J]. Polym. Mater. Sci. Eng., 2010, 26(1): 26–28

Palacios M, Puertas F, Bowen P, et al. Effect of PCs Superplasticizers on the Rheological Properties and Hydration Process of Slag-blended Cement Slurrys[J]. J. Mater. Sci., 2009, 44(10): 2 714–2 723

Yoshioka K, Tazawa E, Kawai K, et al. Adsoprtion Characteristics of Superplasticizers on Cement Component Minerals[J]. Cem. Concr. Compos., 2002, 32(10): 1 507–1 513

Papayianni I, Tsohos G, Oikonomou N, et al. Influence of Superplasticizer Type and Mix Design Parameters on the Performance of Them in Concrete Mixtures[J]. Cem. Concr. Compos., 2005, 27(2): 217–222

Li CZ, Feng NQ, Li YD, et al. Effect s of Polyethlene Oxide Chains on the Performance of Polycarboxylate-type Water-reducers [J]. Cem. Concr. Res., 2005, 35(5): 867–873

Li S, Wen ZY. Dispersibility and Airentraining Performance of Polycarboxylate-type Water Reducers[J]. J. Chin. Ceram. Soc., 2009, 37(4): 616–621

Jiang YQ, Gong MZ. Effect of Superplasticizer Type on Early Age Hydration of Cement[C]. In: 1st International Conference on Microstructure Related Durability of Cementitious Composites, Southeast Univ., 2008

Pei MS, Li C, Wang ZF. The Synthesis of Carboxyl Calcium Lignosulfonate and Its Applications as Water reducer[J]. J. Dispersion Sci. Technol., 2008, 29(4): 530–534

Wu SS, Luo YL, Ran QP. Effects of Comb Copolymer PAA-g-MPEO on Rheological and Dispersion Properties of Aqueous CaCO3 Suspensions[J]. Polym. Bull., 2007, 59(3): 363–369

Chang W, Li H, Wei M. Effects of Polycarboxylic Acid Based Superplasticiser on Properties of Sulphoaluminate Cement[J]. Mater. Res. Innovations, 2009, 13(1): 7–10

Deng SS, Ran QP, Wu SS. Effect of PAA-g-MPEO Comb Polymer on TiO2 Suspensions[J]. Polym. plast. Technol. Eng., 2008, 47(12): 1 278–1 282

Gong JL, Guan XM, Zhang RY, et al. Development and Study of a New Polycarboxylic Series Concrete High Performance Water-Reducer[J]. J. Henan Polyt. Univ., 2006, 25(1): 65–68

Etsuo S, Kazuo Y, Akira O. Molecular Structure and Dispersionadsorption Mechanisms of Comb-type Superplasticizers Used in Japan[J]. J. Adv. Concr. Technol., 2003, 1(1): 16–25

Kazuo Y, Shoichi O, Shunsuke H. Controlling of the Adsorption and Dispersing Force of Polyacrylic-type Superplasticizer by Sulfateion Concentration in Aqueous Phase[J]. Cem. Concr. Res., 2001, 31(2): 375–383

Zhang ZQ, Ding XC, Wei FH, et a1. Synthesis of Macromonomer for Polycarboxylic Acid Type Water-reducers[J]. J. Chongqing Building Univ., 2007, 29(4): 111–114

Zhu BW, Xi Q, Gao H, et a1. The Relationship between Structure and Properties of Copolymers of Polycarboxylate SuperpIasticizer[J]. J. Wuhan Inst. of Chem. Technol., 2005, 27(1): 15–19

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Fujian Education Department (Nos. JA11329, JA12412), and the Quanzhou (Fujian) Technology Research and Development Program (No. 2010G7)

Rights and permissions

About this article

Cite this article

Chen, B. Synthesis of a macromer, MPEGAA, used to prepare an AMPS-modified polyacrylic acid superplasticizer. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 28, 1186–1190 (2013). https://doi.org/10.1007/s11595-013-0842-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-013-0842-y