Abstract

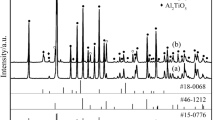

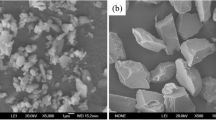

Porous mullite ceramics were fabricated from pyrolysis of nanometer alumina powders filled silicone resin. At 1573 K, the mixture of nanometer γ-Al2O3 and silicone resin can be entirely transformed to mullite in air. The effects of shaping pressure on microstructure and mechanical property were investigated. Increasing shaping pressure leads to decrease in open porosity and average pore size, narrower pore size distribution, and improvement in flexural strength. With a shaping pressure of 43 MPa, nanoporous mullite ceramics with an average pore size of 50 nm can be obtained, showing 33% in open porosity and 42 MPa in flexural strength. The microstructure of porous mullite ceramics consists of dense region and loose region.

Similar content being viewed by others

References

Atisivan R, Bose S, Bandyopadhyay A. Porous Mullite Performs via Fused Deposition[J]. J. Am. Ceram. Soc., 2001, 84(1): 221–223

Liu YF, Liu XQ, Wei H, et al. Porous Mullite Ceramics from National Clay Produced by Gel Casting[J]. Ceram. Inter., 2001, 27(1): 1–7

Miao X. Porous Mullite Ceramics from Natural Topaz[J]. Mater. Lett., 1999, 38(2): 167–172

Schneider H, Schreuer J, Hildmann B. Structure and Properties of Mullite-A Review[J]. J. Eur. Ceram. Soc., 2008, 28: 329–344

Okada K, Uchiyama S, Isobe T, et al. Capillary Rise Properties of Porous Mullite Ceramics Prepared by an Extrusion Method Using Organic Fibers as the Pore Former[J]. J. Eur. Ceram. Soc., 2009, 29: 2 491–2 497

Esharghawi A, Penot C, Nardou F. Contribution to Porous Mullite Synthesis from Clays by Adding Al and Mg Powders[J]. J. Eur. Ceram. Soc., 2009, 29: 31–38

She JH, Ohji T. Fabrication and Characterization of Highly Porous Mullite Ceramics[J]. Mater. Chem. Phys., 2003, 80(3): 610–614

Chen YF, Chang YH, Wang MC, et al. Effects of Al2O3 Addition on the Phases, Flow Characteristics and Morphology of the Porous Kaolin Ceramics[J]. Mater. Sci. Eng. A, 2004, 373: 221–228

Li SJ, Li N. Effects of Composition and Temperature on Porosity and Pore Size Distribution of Porous Ceramics Prepared from Al(OH)3 and Kaolinite Gangue[J]. Ceram. Inter., 2007, 33(4): 551–556

Juettner T, Moertel H, Svinka V, et al. Structure of Kaoline-Alumina Based Foam Ceramics for High Temperature Applications[J]. J. Eur. Ceram. Soc., 2007, 27(2–3): 1 435–1 441

Liu YF, Liu XQ, Tao SW, et al. Kinetics of the Reactive Sintering of Kaolinite-Aluminum Hydroxide Extrudate[J]. Ceram. Inter., 2002, 28(5): 479–486

Bernardo E, Colombo P, Pippel E, et al. Novel Mullite Synthesis Based on Alumina Nanoparticles and a Preceramic Polymer[J]. J. Am. Ceram. Soc., 2006, 89(5): 1 577–1 583

Sorarù GD, Kleebe HJ, Ceccato R, et al. Development of Mullite-SiC Nanocomposites by Pyrolysis of Filled Polymethylsiloxane Gels[J]. J. Eur. Ceram. Soc., 2000, 20: 2 509–2 517

Michalet T, Parlier M, Beclin F, et al. Elaboration of Low Shrinkage Mullite by Active Filler Controlled Pyrolysis of Siloxanes[J]. J. Eur. Ceram. Soc., 2002, 22: 143–152

Michalet T, Parlier M, Addad A, et al. Formation at Low Temperature with Low Shrinkage of Polymer/Al/Al2O3 Derived Mullite[J]. Ceram. Inter., 2001, 27: 315–319

Anggono J, Derby B. Mullite Formation from the Pyrolysis of Aluminium-Loaded Polymethylsiloxanes: The Influence of Aluminium Powder Characteristics[J]. J. Eur. Ceram. Soc., 2006, 26: 1 107–1 119

Suttor D, Kleebe HJ, Ziegler G. Formation of Mullite from Filled Siloxanes[J]. J. Am. Ceram. Soc., 1997, 80(10): 2 541–2 548

Griggio F, Bernardo E, Colombo P, et al. Kinetic Studies of Mullite Synthesis from Alumina Nanoparticles and a Preceramic Polymer[J]. J. Am. Ceram. Soc., 2008, 91(8): 2 529–2 533

Ma QS, Ma Y, Chen ZH. Fabrication and Characterization of Nanoporous SiO2 Ceramics via Pyrolysis of Silicone Resin Filled with Nanometer SiO2 Powders[J]. Ceram. Inter., 2010, 36(8): 2 269–2 272

Li D, Hwang ST. Pyrolysis Kinetics of Highly Crosslinked Polymethylsiloxane by TGA[J]. J. Appl. Polym. Sci., 1992, 44: 1 979–1 991

Bartsch M, Saruhan B, Schmücker M, et al. Novel Low-Temperature Processing Route of Dense Mullite Ceramics by Reaction Sintering of Amorphous SiO2-Coated γ-Al2O3 Particle Nanocomposites[J]. J. Am. Ceram. Soc., 1999, 82(6): 1 388–1 392

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Hunan Provincial Natural Science Foundation of China (No. S2010J504B) and the National Natural Science Foundation of China (No. 91116001)

Rights and permissions

About this article

Cite this article

Ma, Q., Tian, H. Fabrication and characterization of porous mullite ceramics from pyrolysis of alumina powders filled silicone resin. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 28, 1082–1084 (2013). https://doi.org/10.1007/s11595-013-0823-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-013-0823-1