Abstract

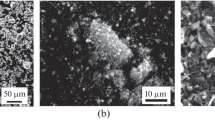

β-SiC nanoparticle reinforced Al matrix (nano-SiCp/Al) composite was prepared by a multistep powder metallurgy strategy including presureless sintering, hot compacting process and hot extrusion. The microstructures of the as-prepared composites were observed by scanning electronic microscopy (SEM), and the mechanical properties were characterized by tensile strength measurement and Brinell hardness test. The experimental results revealed that the tensile strength of the composite with the addition of 5wt% β-SiC nanoprticles could be increased to 215 MPa, increasing by 110% compared with pure Al matrix. Comparative experiments reflected that the β-SiC nanoprticles showed significant reinforcement effect than traditional α-SiC micro-sized particles. The preparation process and sintering procedure were investigated to develop a cost effective preparation strategy to fabricate nano-SiCp/Al composite.

Similar content being viewed by others

References

Ibrahim IA, Mohamed FA, Lavernia EJ. Particulate Reinforced Metal Matrix Composites — A Review[J]. J. Mater. Sci., 1991, 26: 1 137–1 156

Lloyd DJ. Aspects of Fracture in Particulate Reinforced Metal Matrix Composites[J]. Acta Metall. Mater., 1991, 39(1): 59–71

Nan CW, Clarke DR. The Influence of Particle Size and Particle Fracture on the Elastic/Plastic Deformation of Metal Matrix Composites[J]. Acta Mater., 1996, 44(9): 3 801–3 811

Harrigan WC. Commercial Processing of Metal Matrix Composites[J]. Mater. Sci. Eng.: A, 1998, 244(1): 75–79

Rajan TPD, Pillai RM, Pai BC. Characterization of Centrifugal Cast Functionally Graded Aluminum-silicon Carbide Metal Matrix Composites[J]. Mater. Characterization, 2010, 61(10): 923–928

Prabu SB, Karunamoorthy L, Kathiresan S, et al. Influence of Stirring Speed and Stirring Time on Distribution of Particles in Cast Metal Matrix Composite[J]. J. Mater. Process. Technol., 2006, 171(2): 268–273

Euh K, Kang SB. Effect of Rolling on the Thermo-physical Properties of SiCp/Al Composites Fabricated by Plasma Spraying[J]. Mater. Sci. Eng: A, 2005, 395(1–2): 47–52

Li W, Chen ZH, Chen D, et al. Thermal Fatigue Behavior of Al-Si/SiCp Composite Synthesized by Spray Deposition[J]. J. Alloys Compd., 2010, 504(1): S522–526

Nicom N, Nomura HR. Melt Infiltration of SiCp Reinforced Al Matrix Composite by Newly Designed Pressure Infiltration Technique[J]. Mater. Sci. Eng: A, 2006, 441(1–2): 97–105

Zahedi AM, Rezaie H, Javadpour J, et al. Processing and Impact Behavior of Al/SiCp Composites Fabricated by the Pressureless Melt Infiltration method[J]. Ceram. Int., 2009, 35(5): 1919–1926

Ortega-Celaya F, Pech-Canul MI, López-Cuevas J, et al. Microstructure and Impact Behavior of Al/SiCp Composites Fabricated by Pressureless Infiltration with Different Types of SiCp[J]. J. Mater. Process. Technol., 2007, 183(2–3): 368–373

Wang HL, Zhang R, Hu X, et al. Characterization of a Powder Metallurgy SiC/Cu-Al Composite[J]. J. Mater. Process. Technol., 2008, 197(1–3): 43–48

Woo KD, Zhang DL. Fabrication of Al-7wt%Si-0.4wt%Mg/SiC Nanocomposite Powders and Bulk Nanocomposites by High Energy Ball Milling and Powder Metallurgy[J]. Curr. Appl. Phys., 2004, 4(2–4): 175–178

Duval-Riviere ML, Coster M, Chermant L, et al. Morphological Characterization of Hot-pressed α-SiC with Al-based Additives Deformed by Compression at High Temperature[J]. J. Eur. Ceram. Soc., 1995, 15(1): 71–80

Lu YX, Lee CS, Li RKY, et al. The Effect of Cold Rolling on the Dynamic Mechanical Responses of SiCp/Al Composites[J]. J. Mater. Process. Technol., 1999, 91(1–3): 215–218

Zhang WL, Gu MY, Wang DZ, et al. Rolling and Annealing Textures of a SiCw/Al Composite[J]. Mater. Lett., 2004, 58(27–28): 3 414–3 418

Li WY, Liao HL, Li CJ, et al. Numerical Simulation of Deformation Behavior of Al Particles Impacting on Al Substrate and Effect of Surface Oxide Films on Interfacial Bonding in Cold Spraying[J]. Appl. Surf. Sci., 2007, 253(11): 5 084–5 091

Xie GQ, Ohashi O, Song MH, et al. Reduction Mechanism of Surface Oxide Films and Characterization of Formations on Pulse Electriccurrent Sintered Al-Mg Alloy Powders[J]. Appl. Surf. Sci., 2005, 241(1–2): 102–106

Yang Y, Lan J, Li XC. Study on Bulk Aluminum Matrix Nano-composite Fabricated by Ultrasonic Dispersion of Nano-sized SiC Particles in Molten Aluminum Alloy[J]. Mater. Sci. Eng.: A, 2004, 380(1–2): 378–383

Moazami-Goudarzi M, Akhlaghi F. Novel Approach Based on in situ Powder Metallurgy (IPM) Method for Embedding of SiC Nanoparticles in Aluminium Powders[J]. Mater. Technol., 2012, 27(2): 158–164

Kollo L, Bradbury CR, Veinthal R, et al. Nano-silicon Carbide Reinforced Aluminium Produced by High-energy Milling and Hot Consolidation[J]. Mater. Sci. Eng.: A, 2011, 528(21): 6 606–6 615

El-Daly AA, Abdelhameed M, Hashish M, et al. Synthesis of Al/SiC Nanocomposite and Evaluation of Its Mechanical Properties Using Pulse Echo Overlap Method[J]. J. Alloys Compd., 2012, 542: 51–58

Saberi Y, Zebarjad SM, Akbari GH. On the Role of Nano-size SiC on Lattice Strain and Grain Size of Al/SiC Nanocomposite[J]. J. Alloys Compd., 2009, 484(1–2): 637–640

Kueck AM, De Jonghe LC. Two-stage Sintering Inhibits Abnormal Grain Growth During β to α Transformation in SiC[J]. J. Eur. Ceram. Soc., 2008, 28(11): 2 259–2 264

Han WZ, Vinogradov A, Hutchinson CR. On the Reversibility of Dislocation Slip During Cyclic Deformation of Al Alloys Containing Shear-resistant Particles[J]. Acta Mater., 2011, 59(9): 3 720–3 736

Taupin V, Berbenni S, Fressengeas C, et al. On Particle Size Effects: An Internal Length Mean Field Approach Using Field Dislocation Mechanics[J]. Acta Mater., 2010, 58(16): 5 532–5 540

Fang QH, Liu YW, Jin B, et al. Effect of Interface Stresses on the Image Force and Stability of an Edge Dislocation Inside a Nanoscale Cylindrical Inclusion[J]. Int. J. Solids. Struct., 2009, 46(6): 1 413–1 422

Khraishi TA, Yan L, Shen YL. Dynamic Simulations of the Interaction between Dislocations and Dilute Particle Concentrations in Metalmatrix Composites (MMCs)[J]. Int. J. Plast., 2004, 20(6): 1 039–1 057

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Research Collaborative Innovation Project of Jiangsu Province, China (BY2009129) and the Science and Technology Project of Suzhou, China (SYG0905)

Rights and permissions

About this article

Cite this article

Wang, L., Wu, H., Wu, X. et al. Preparation and mechanical properties of β-SiC nanoparticle reinforced aluminum matrix composite by a multi-step powder metallurgy process. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 28, 1059–1063 (2013). https://doi.org/10.1007/s11595-013-0819-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-013-0819-x