Abstract

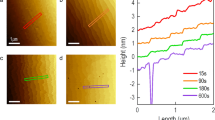

CeO2 and Ce0.8M0.2O2−d films (M = Mn, Y, Gd, Sm, Nd and La) with (00l) preferred orientation have been prepared on biaxially textured Ni-W substrates by metal organic decomposition (MOD) method. The factors influencing the formation of cracks on the surface of these CeO2 and doped CeO2 films on Ni-W substrates were explored by X-ray diffraction (XRD), scanning electron microscopy (SEM) analysis, atomic force microscopy (AFM) and differential scanning calorimetry (DSC). The results indicate that many factors, such as the change of the ionic radii of doping cations, the transformation of crystal structure and the formation of oxygen vacancies in lattices at high annealing temperature, may be related to the formation of cracks on the surface of these films. However, the crack formation shows no dependence on the crystal lattice mismatch degree of the films with Ni-W substrates. Moreover, the suppression of surface cracks is related to the change of intrinsic elasticity of CeO2 film with doping of cations with a larger radius. SEM and AFM investigations of Ce0.8M0.2O2−d (M = Y, Gd, Sm, Nd and La) films reveal the dense, smooth and crack-free microstructure, and their lattice parameters match well with that of YBCO, illuminating that they are potentially suitable to be as buffer layer, especially as cap layer in multi-layer architecture of buffer layer for coated conductors.

Similar content being viewed by others

References

X W Lu, X Z Li, F Chen, et al. Hydrothermal Synthesis of Prism-like Mesocrystal CeO2[J]. J. Alloys Compd., 2009, 476: 958–962

K Develos-Bagarinao, H Yamasaki, Y Nakagawa, et al. Comparative Studies of Nanostructural and Morphological Evolution of CeO2 Thin Flms Induced by High-Temperature Annealing[J]. Nanotechnology, 2007, 18: 165 605–165 608

A N Khodan, J P Contour, D Michel, et al. ZrO2-CeO2 and CeO2-La2O3 Film Growth on Oxide Substrates and Their Applications in Oxide Heterostructures [J]. J. Cryst. Growth, 2000, 209: 828–841

M Y Li, X Z Zhao, B Ma, et al. Effect of CeO2 Buffer Layer Thickness on the Structures and Properties of YBCO Coated Conductors [J]. Appl. Surf. Sci., 2007, 253: 7 172–7 177

A C Wang, J A Belot, T J Marks, et al. Buffers for High Temperature Superconductor Coatings: Low Temperature Growth of CeO2 Films by Metal-Organic Chemical Vapor Deposition and Their Implementation as Buffers [J]. Physica C, 1999, 320: 154–160

J Xiong, B W Tao, W F Qin, et al. Reel-to-Reel Continuous Simultaneous Double-Sided Deposition of Highly Textured CeO2 Templates for YBa2Cu3O7−d Coated Conductors[J]. Supercond. Sci. Technol., 2008, 21: 025016

S S Wang, Z Han, W Schmidt, et al. Chemical Solution Growth of CeO2 Buffer and YBCO Layers on IBAD-YSZ/Hastelloy Templates [J]. Supercond. Sci. Technol., 2005, 18: 1 468–1 472

M S Bhuiyan, M Paranthaman, S Sathyamurthy, et al. MOD Approach for the Growth of Epitaxial CeO2 Buffer Layers on Biaxially Textured Ni-W Substrates for YBCO Coated Conductors [J]. Supercond. Sci. Technol., 2003, 16: 1 305–1 309

M P Paranthaman, S Sathyamurthy, X P Li, et al. Modified Lanthanum Zirconium Oxide Buffer Layers for Low-Cost, High Performance YBCO Coated Conductors [J]. Physica C, 2010, 470: 352–356

Y Ota, J Sakuma, Y Kimura, et al. Relationship between Superconducting Properties of EuBa2Cu3O7 Thin Films and Surface Morphology of CeO2 Buffer Layers on R-Al2O3[J]. Physica C, 2006, 445–448: 849–852

I Yamaguchi, M Sohma, K Tsukada, et al. Preparation of Large-Size Y123 Films on CeO2-Buffered Sapphire Substrates by MOD Using a Low-Cost Vacuum Technique [J]. Physica C, 2007, 463–465: 549–553

G Li, M H Pu, R P Sun, et al. Sm-Doped CeO2 Single Buffer Layer for YBCO Coated Conductors by Polymer Assisted Chemical Solution Deposition (PACSD) Method [J]. J. Alloys Compd., 2008, 466: 429–434

S Chen, S S Wang, K Shi, et al. Biaxially Textured CeO2 Seed Layers and Thin Films on Ni Substrates by Chemical Solution Deposition Using Inorganic Cerium Nitrate as a Precursor [J]. Physica C, 2005, 419: 7–12

S Oh, J Yoo, K Lee, et al. Comparative Study on the Crack Formations in the CeO2 Buffer Layers for YBCO Films on Textured Ni Tapes and Pt Tapes [J]. Physica C, 1998, 308: 91–98

Y Sutoh, K Nakaoka, J Matsuda, et al. Effective Thickness of CeO2 Buffer Layer for YBCO Coated Conductor by Advanced TFA-MOD Process [J]. Physica C, 2007, 463–465: 571–573

S Chen, Z Sun, K Shi, et al. Preparation and Crystalline Qualities of SrTiO3 and CeO2 Buffer Layers Fabricated on Ni Substrates via a Sol-Gel Method for YBCO Coated Conductors [J]. Physica C, 2004, 412–414: 871–876

K Knoth, B Schlobach, R Hühne, et al. La2Zr2O7 and Ce-Gd-O Buffer Layers for YBCO Coated Conductors Using Chemical Solution Deposition [J]. Physica C, 2005, 426–431: 979–984

M Coll, J Gàzquez, R Hühne, et al. All Chemical YBa2Cu3O7 Superconducting Multilayers: Critical Role of CeO2 Cap Layer Flatness [J]. J. Mater. Res., 2009, 24(4): 1 446–1 455

Y J Kim, S Thevuthasan, V Shutthananadan, et al. Growth and Structure of Epitaxial Ce1−x ZrxO2 Thin Films on Yttria-Stabilized Zirconia (111) [J]. J. Electron. Spectrosc. Relat. Phenom., 2002, 126: 177–190

Y P Fu, S H Chen, J J Huang. Preparation and Characterization of Ce0.8M0.2O2−d (M=Y, Gd, Sm, Nd, La) Solid Electrolyte Materials for Solid Oxide Fuel Cells[J]. Int. J. Hydrogen Energy, 2010, 35(2): 745–752

M Pan, Z Huang, H F Ma, et al. The Influence of Impurity on the Critical Thickness of the CeO2 Buffer Layer for Coated Conductors [J]. Sci. China, Ser. G-Phys. Mech. Astron., 2009, 52(7): 993–996

T Kawada, N Sakai, H Yokokawa, et al. Electrical Properties of Transition-Metal-Doped YSZ [J]. Solid State Ionics, 1992, 53–56: 418–425

A Kossoy, A I Frenkel, Q Wang, et al. Local Structure and Strain-Induced Distortion in Ce0.8Gd0.2O1.9[J]. Adv. Mater., 2010, 22: 1 659–1 662

K H Müller. Stress and Microstructure of Sputter-Deposited Thin Films, Molecular Dynamics Investigations[J]. J. Appl. Phys., 1987, 62: 1 796–1 799

Author information

Authors and Affiliations

Corresponding authors

Additional information

Funded by the National Natural Science Foundation of China and National 863 Program of China (Nos. 50872115 and 2009AA03Z203)

Rights and permissions

About this article

Cite this article

Wang, Y., Zhou, L., Yu, Z. et al. Growth and characterization of doped CeO2 buffers on Ni-W substrates for coated conductors using metal organic deposition method. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 27, 471–476 (2012). https://doi.org/10.1007/s11595-012-0487-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-012-0487-2