Abstract

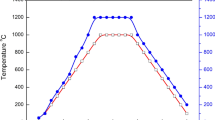

The effects of activated sintering technology of H2 atmosphere sintering on the microstructure and properties of W-15Cu alloy using ultrafine W-15Cu composite powder fabricated by spray drying & calcining-continuous reduction technology were investigated. The experimental results showed that W-15Cu alloy, consolidated by activated sintering technology of H2 atmosphere sintering for 1 h at 1300 °C, with 98.5 % relative density, transverse rupture strength 1218 MPa, Vickers hardness HV0.5 378, average grain size about 1.2 μm and thermal conductivity 192 W/m·K, was obtained. In comparison to the normal sintering process, activated sintering process to W-15Cu alloy could be achieved at lower sintering temperature. Furthermore, better properties in activated sintered compacts were obtained, and activated sintering process resulted in finer microstructure and excellent properties.

Similar content being viewed by others

References

X L Shi, H Yang, S Wang. Spark Plasma Sintering of W-15Cu Alloy from Ultrafine Composite Powder Prepared by Spray Drying and Calcining-continuous Reduction Technology[J]. Mater. Charact., 2009, 60(2): 133–137

X L Shi, H Yang, S Wang, et al. Characterization of W-20Cu Ultrafine Composite Powder Prepared by Dpray Drying and Calcining-continuous Reduction Technology[J]. Mater. Chem. Phys., 2007, 104(2–3): 235–239

X L Shi, H Yang, G Q Shao, et al. Fabrication and Properties of W-Cu Alloy Reinforced by Multi-walled Carbon Nanotubes[J]. Mater. Sci. Eng., A, 2007, 457(1–2):18–23

S H Hong, B K Kim. Fabrication of W-20wt%Cu Composite Nanopowder and Sintered Alloy with High Thermal Conductivity[J]. Mater. Lett., 2003, 57(18):2761–2767

D G Kim, K W Lee, S T Oh, et al. Preparation of W-Cu Nanocomposite Powder by Hydrogen-reduction of ball-milled W and CuO Powder Mixture[J]. Mater. Lett., 2004, 58(7–8): 1199–1203

E S Yoon, J S Lee, S T Oh, et al. Microstructure and Sintering Behavior of W-Cu Nanocomposite Powder Produced by Thermo-chemical Process[J]. Int. J. Refract. Met. Hard Mater., 2002, 20(3): 201–206

F Doré, S Lay, Eustathopoulos N, et al. Segregation of Fe During the Sintering of Doped W-Cu Alloys[J]. Scripta Mater., 2003, 49(3): 237–242

M Amirjan, K Zangeneh-Madar, N Parvin. Evaluation of Microstructure and Contiguity of W/Cu Composites Prepared by Coated Tungsten Powders[J]. Int. J. Refract. Met. Hard Mater., 2009, 27(4): 729–733

M Ardestani, H Arabi, H R Rezaie, et al. Synthesis and Densification of W-30wt%Cu Composite Powders Using Ammonium Meta Tungstate and Copper Nitrate as Precursors[ J]. Int. J. Refract. Met. Hard Mater., 2009, 27(4): 796–800

K Zangeneh-Madar, M Amirjan, N Parvin. Improvement of physical properties of Cu-infiltrated W Compacts via Electroless Nickel Plating of Primary Tungsten Powder[J]. Surf. Coat. Technol., 2009, 203(16): 2333–2336

Y P Li, S Yu. Thermal-mechanical Process in Producing High Dispersed Tungsten-copper Composite Powder[J]. Int. J. Refract. Met. Hard Mater., 2008, 26(6): 540–548

X H Yang, P Xiao, S H Liang, et al. Alloying Effect of Ni And Cr on the Wettability of Copper on W Substrate[J]. Acta. Metall. Sin. (English Lett.), 2008, 21(5): 369–379

X L Shi, H Yang, X L Duan, et al. A Activated Sintering Method of Preparing Tungsten & Copper Alloy[P]. Chinese Invention Patent, ZL 2007 1 0053252.0, 2009.4.15

R M German. Enhanced Sintering Through Second Phase Additions[J]. Powder Metall., 1985, 28(1): 7–11

Z F Wang, G S Jiang, Z C Liu. Effect of Cu Purity on Thermal Conductivity of W-Cu Composites[J]. J. Cent. South Univ. Technol., 1999, 30(2): 186–188 (In Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Project for Science and Technology Plan of Wuhan City (200910321092) and the Fundamental Research Funds for the Central Universities( 2010-II-020)

Rights and permissions

About this article

Cite this article

Shi, X., Wang, S., Yang, X. et al. Effects of activated sintering process on properties and microstructure of W-15Cu alloy. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 25, 909–913 (2010). https://doi.org/10.1007/s11595-010-0118-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-010-0118-8