Abstract

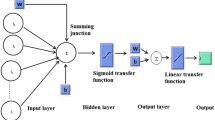

50CrVA cold-rolled spring steel strip was used to fabricate the diaphragm of the automotive horn. The material parameters which were taken into account in the design of the diaphragm involve elongation, elastic limit, Young’s modulus, yield strength and tensile strength. The tempering process was carried out in order to enable the diaphragm to possess the excellent mechanical properties, such as high elastic limit, high fatigue strength and perfect stress relaxation resistance. As a nonlinear information processing system, the backpropagation artificial neural network (BPANN) was applied to predict and simulate the relationship between the mechanical properties of the diaphragm and the tempering process parameters. Experimental results show that a BPANN with 3-8-5 architecture is capable of predicting the relationship between the mechanical properties of the diaphragm and the tempering temperature successfully and lays the profound foundations for optimizing the design of the diaphragm. BPANN simulation results show that the tempering temperature ranging from 380 to 420 °C contributes to enhancing the comprehensive mechanical properties of the diaphragm including high Young’s modulus, high elastic limit and high fatigue strength.

Similar content being viewed by others

References

I A Basheer, M Hajmeer. Artificial Neural Networks: Fundamentals, Computing, Design, and Application[J]. Journal of Microbiological Methods, 2000, 43(1): 3–31

A Shafyei, S H Mousavi Anijdan, A Bahrami. Prediction of Porosity Percent in Al-Si Casting Alloys Using ANN[J]. Materials Science and Engineering A, 2006, 431(1–2): 206–210

Ragip Ince. Prediction of Fracture Parameters of Concrete by Artificial Neural Networks[J]. Engineering Fracture Mechanics, 2004, 71(15): 2143

S Malinov, W Sha, Z Guo. Application of Artificial Neural Network for Prediction of Time-temperature-transformation Diagrams in Titanium Alloys[J]. Materials Science and Engineering A, 2000, 283(1–2): 1–10

R H Wu, H B Chang, T Y Hsu, et al. Prediction of the Flow Stress of 0.4C-1.9Mn-1.0Ni-0.2Mo Steel during Hot Deformation[J]. Journal of Materials Processing Technology, 2001, 116(2–3): 211–218

Shashi Kumar, Sanjeev Kumar, Prakash, et al. Prediction of Flow Stress for Carbon Steels Using Recurrent Self-organizing Neuro Fuzzy Networks[J]. Expert Systems with Applications, 2007, 32(6): 777–788

K Genel. Application of Artificial Neural Network for Predicting Strain-life Fatigue Properties of Steels on the Basis of Tensile Tests[J]. International Journal of Fatigue, 2004, 26(10): 1027–1035

T Todd Pleune, K Chopra Omesh. Using Artificial Neural Networks to Predict the Fatigue Life of Carbon and Low-alloy Steels[J]. Nuclear Engineering and Design, 2000, 197(1–2): 1–12

E Haque Mohammed, K V Sudhakar. ANN Back-propagation Prediction Model for Fracture Toughness in Microalloy Steel[J]. International Journal of Fatigue, 2002, 24(9): 1003–1010

S Malinov, W Sha. Application of Artificial Neural Networks for Modelling Correlations in Titanium Alloys[J]. Materials Science and Engineering A, 2004, 365(1–2): 202–211

F Briceno Jorge, Hazim El-Mounayri, Snehasis Mukhopadhyay. Selecting an Artificial Neural Network of Efficient Modeling and Accurate Simulation of the Milling Process[J]. International Journal of Machine Tools & Manufacture, 2002, 42(6): 663–674

A Downes, P Hartley. Using an Artificial Neural Network to Assist Rolling Design in Cold-rolling Forming Processes[J]. Journal of Materials Processing Technology, 2006, 177(1–3): 319–322

W J Liu, Q Liu, F Ruan, et al. Springback Prediction of Sheet Metal Forming Based on GA-ANN[J]. Journal of Materials Processing Technology, 2007, 187–188: 227–231

Jamal Sheikh-Ahmad, Janet Twomey. ANN Constitutive Model for High-rate Deformation of Al7075-T6[J]. Journal of Materials Processing Technology, 2007, 186(1–3): 339–345

S Y Jiang, P Li, K M Xue. Application of BPANN in Spinning Deformation of Thin-walled Tubular Parts with Longitudinal Inner Ribs[J]. Journal of Central South University of Technology, 2004, 11(1): 27–30

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Research Foundation of Harbin Engineering University (No. HEUFT06040)

Rights and permissions

About this article

Cite this article

Jiang, S., Zhao, L. & Wu, G. Prediction of mechanical properties of 50CrVA tempered steel strip for horn diaphragm based on BPANN. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 24, 791–795 (2009). https://doi.org/10.1007/s11595-009-5791-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-009-5791-0