Abstract

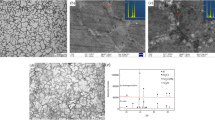

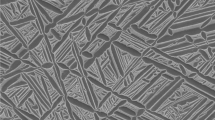

Hot compressive behaviors of Ti-6Al-2Zr-1Mo-1V alloy at 800 °C, as well as the evolution of microstructure during deformation process, were investigated. The experimental results show that flow stress increases to a peak stress followed by a decease with increasing strain, and finally forms a stable stage. Dislocations are generated at the interface of α/β phase, and the phase interface and dislocation loops play an important role in impeding the movement of dislocation. As strain increasing, micro-deformation bands with high-density dislocation are formed, and dynamic recrystallizaton occurs finally. XRD Fourier analysis reveals that dislocation density increases followed by a decrease during compressive deformation, and falls into the range from 1010 to 1011 cm−2.

Similar content being viewed by others

References

Gilbert J R B. The Use of Titanium[J]. Materials Science and Technology, 1985, (1): 257–259

Kimura K, Ishii M, Yoshimura H. An Analysis of Deformation, Temperature, and Microstructure for Hot Extruded Titanium Alloy[J]. Metallurgical Transactions B, 1993, 24B: 139–144

Seshacharyulu T, Medeiros S C, Frazier W G, Prasad Y V R K. Microstructural Mechanisms during Hot Working of Commercial Grade Ti-6Al-4V with Lamellar Starting Structure[J]. Materials Science and Engineering A, 2002, 325: 112–125

Ding R, Guo Z X, Wilson A. Microstructural Evolution of A Ti-6Al-4V Alloy during Thermomechanical Processing[J]. Materials Science and Engineering A, 2002, 327: 233–245

Seshacharyulu T, Medeiros S C, Frazier W G, et al. Hot Working of Commercial Ti-6Al-4V with An Equiaxed α-β Microstructure: Materials Modeling Considerations[J]. Materials Science and Engineering A, 2000, 284: 184–194

Seshacharyulu T, Medeiros S C, Morgan J T, et al. Hot Deformation Mechanisms In ELI Grade Ti-6A1-4V[J]. Scripta Materialia, 1999, 41(3): 283–288

Seshacharyulu T, Medeiros S C, Morgan J T, et al. Hot Deformation and Microstructural Damage Mechanisms in Extra-low Interstitial (ELI) Grade Ti-6Al-4V[J]. Materials Science and Engineering A, 2000, 279: 289–299

Semiatin S L, Thomas J E, Dadras P. Processing-Microstructure Relationships for Ti-6AI-2Sn-4Zr-2Mo- 0.1Si[J]. Metallurgical Transactions A, 1983, 14: 2363–2374

Xu Wenchen, Shan Debin, Li Chunfeng, et al. Study on the Dynamic Hot Compression Behavior and Deformation Mechanism of TA15 Titanium Alloy[J]. Journal of Aeronautical Materials, 2005, 25(4): 10–15(in Chinese)

Glavicic M G, Semiatin S L. X-ray Line-broadening Investigation of Deformation during Hot Rolling of Ti-6Al-4V with a Colony-alpha Microstructure[J]. Acta Materialia, 2006, 54: 5337–5347

Chen Wanjun, Gao Zhanmin, Huang Jiaju. A Study on Dislocation Density and Dislocation Configuration in 20CrMnTi steel[J]. Journal of Jilin University(Engineering and Technology Edition), 2004, 34(1): 31–34(in Chinese)

Wang Rizhi. Hot Deformation and Dynamic Restoration of Low Carbon Steels in (F+A) Two-Phase Range[D]. Harbin: Harbin Institute of Technology, 1993(in Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Zhu, J., Wang, Y. et al. The dislocation sub-structure evolution during hot compressive deformation of Ti-6Al-2Zr-1Mo-1V alloy at 800 °C. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 24, 202–205 (2009). https://doi.org/10.1007/s11595-009-2202-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-009-2202-5