Abstract

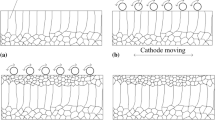

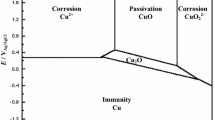

With the global proliferation of 5G technology, advancing electronic interconnection technologies has become critically important. The development of high-quality electrolytic copper foils, essential for efficient signal transmission, has garnered considerable attention. To mitigate the "skin effect" that could impair signal transmission and to ensure robust adhesion of electrolytic copper foils to the substrate, it's necessary to roughen the copper foils. This roughening process aims to substantially enhance the peel strength of the copper foils without exceeding the bounds of acceptable roughness. An effective strategy to achieve this involves the use of additives to refine the micro-coarsened surface of the copper foils. In this context, we have explored the impact of additives such as carrageenan, guar gum, and SPS on the surface morphology, roughness, and peel strength of electrolytic copper foils. Three types of additives can improve the performance of micro-roughened copper foil. Through electrochemical tests, it was found that all three types of additives have the effect of increasing cathodic polarization. The adsorption behavior of different additives was studied through theoretical calculations. By hybriding the three additives, two micro-coarsening systems were screened to obtain the lowest roughness and the highest peel strength, respectively. At the same time, the relationship between peel strength and surface area was verified, with the larger surface area resulting in greater peel strength. Finally, the synergistic effect of the three additives on increasing cathodic polarization was verified through chronopotentiometry.

Graphical Abstract

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

An JP, Yang K, Wu JS, Ye N, Guo S, Liao ZF (2017) Achieving sustainable ultra-dense heterogeneous networks for 5G. IEEE Commun Mag 55(12):84–90. https://doi.org/10.1109/mcom.2017.1700410

Jao CK et al (2018) WISE: a system-level simulator for 5G mobile networks. IEEE Wirel Commun 25(2):4–7. https://doi.org/10.1109/mwc.2018.8352614

Navarro-Ortiz J, Romero-Diaz P, Sendra S, Ameigeiras P, Ramos-Munoz JJ, Lopez-Soler JM (2020) A survey on 5G usage scenarios and traffic models. IEEE Commun Surv Tutor 22(2):905–929. https://doi.org/10.1109/comst.2020.2971781

Hao R, Zhao Y, Su J, Yang J, Tan C, Song X (2023) Bonding mechanism of laser joining of Poly-Ether-Ether-Ketone film which used for 5G antenna substrate to copper foil. J Manuf Process 108:153–164. https://doi.org/10.1016/j.jmapro.2023.11.005

He X, Huang LJ, Xiao MZ, Yu CY, Li E, Shao WH (2023) Investigation on the new reliability issues of PCB in 5G millimeter wave application. Microelectron Int. https://doi.org/10.1108/mi-01-2023-0001

Jia L, Yang H, Wang Y, Zhang B, Liu H, Hao J (2020) Research on temperature-assisted laser transmission welding of copper foil and polyethylene terephthalate. J Manuf Process 57:677–690. https://doi.org/10.1016/j.jmapro.2020.07.026

Huang G et al (2023) Mechanism investigation of micro-drill fracture in PCB large aspect ratio micro-hole drilling. J Mater Process Technol 316:117962. https://doi.org/10.1016/j.jmatprotec.2023.117962

Onfroy G, Saida M (1996) Development of new electrodeposited copper foil. Trans Inst Met Finish 74:133–137. https://doi.org/10.1080/00202967.1996.11871112

Li XS et al (2009) Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 324(5932):1312–1314. https://doi.org/10.1126/science.1171245

Li JK, Ren XP, Ling Z, Wang HB (2020) Improving bending property of copper foil by the combination of double-rolling and cross rolling. J Mater Res Technol 9(3):6922–6927. https://doi.org/10.1016/j.jmrt.2020.02.004

Uno T, Okuno Y, Tsuruta T, Nishi Y, Fukutake S (2020) Surface-treated copper foil, and copper-clad laminate and printed wiring board using same. Patent Appl. US10701811B2, 06–30

Matsuda M, Sakai H, Tomonaga S, Dobashi M (2010) Electrodeposited copper foil, its manufacturing method, surface-treated electrodeposited copper foil using the electrodeposited copper foil, and copper-clad laminate and printed wiring board using the surface-treated electrodeposited copper foil. Patent Appl. US2010038115A1

Yamamoto T, Kataoka T, Hirasawa Y, Takahashi N (2003) Surface treated copper foil, electrodeposited copper foil with carrier, manufacture method for the electrodeposited copper foil with carrier, and copper clad laminate. Patent Appl. US20030148136A1

Song RG et al (2020) Sandwiched graphene clad laminate: a binder-free flexible printed circuit board for 5g antenna application. Adv Eng Mater 22(10):2000451. https://doi.org/10.1002/adem.202000451

Zee A, Massey R, Reischer H (2009) Impact of surface treatment on high frequency signal loss characteristics. In: International microsystems, packaging, assembly and circuits technology conference

Shi H et al (2023) Dual-anchor anti-corrosion coating of copper foil for high-speed interconnects. J Ind Eng Chem 126:371–381. https://doi.org/10.1016/j.jiec.2023.06.026

Hur J, Lee J, Kim B-Y, Yoo MJ, Seo J-H (2022) Formation of a robust Cu adhesive layer on poly(ether ether ketone) via self UV-initiated surface polymerization. J Ind Eng Chem 112:307–315. https://doi.org/10.1016/j.jiec.2022.05.026

Xiao Y et al (2023) Effect of additives on microstructure and properties of the coarsened layer of very low profile (HVLP) copper foil. J Appl Electrochem 53(12):2331–2346. https://doi.org/10.1007/s10800-023-01930-y

Wang LJ et al (2023) Preparation of an ultra-low profile and high peel strength copper foil with rice-grain microstructures. Mater Adv. https://doi.org/10.1039/d3ma00565h

Hebert KR (2001) Analysis of current-potential hysteresis during electrodeposition of copper with additives. J Electrochem Soc 148(11):C726–C732. https://doi.org/10.1149/1.1408634

Dow WP, Chiu YD, Yen MY (2009) Microvia filling by cu electroplating over a Au seed layer modified by a disulfide. J Electrochem Soc 156(4):D155–D167. https://doi.org/10.1149/1.3078407

Liu LL et al (2021) Trace bis-(3-sulfopropyl)-disulfide enhanced electrodeposited copper foils. J Mater Sci Technol 74:237–245. https://doi.org/10.1016/j.jmst.2020.10.019

Ku CK, Ho CH, Chen TS, Lee YD (2007) Synthesis and characterization of pyridine-containing poly(imide-siloxane)s and their adhesion to copper foil. J Appl Polym Sci 104(4):2561–2568. https://doi.org/10.1002/app.24719

Chan PF, Ren RH, Wen SI, Chang HC, Dow WP (2017) Effects of additives and convection on Cu foil fabrication with a low surface roughness. J Electrochem Soc 164(9):D660–D665. https://doi.org/10.1149/2.0101712jes

Xu P et al (2024) Preparation of electrodeposited copper foils with ultrahigh tensile strength and elongation: a functionalized ionic liquid as the unique additive. Chem Eng J 484:149557. https://doi.org/10.1016/j.cej.2024.149557

Yung KC, Wang J, Yue TM (2007) Surface characterization of pre-treated copper foil used for PCB lamination. J Adhes Sci Technol 21(5–6):363–377. https://doi.org/10.1163/156856107780474939

Pu XJ et al (2021) Understanding and calibration of charge storage mechanism in cyclic voltammetry curves. Angew Chem-Int Ed 60(39):21310–21318. https://doi.org/10.1002/anie.202104167

Li YQ et al (2023) Investigation of novel suppressor Nitrotetrazolium Blue chloride on cobalt superconformal growth. J Manuf Process 101:15–24. https://doi.org/10.1016/j.jmapro.2023.05.059

Li R et al (2024) Theoretical and experimental studies on the electrodeposited nanocrystalline Ag coatings from a novel Ag2O-based non-cyanide electrolyte. J Ind Eng Chem 131:432–440. https://doi.org/10.1016/j.jiec.2023.10.046

Li YQ et al (2023) Experimental and theoretical study of the new leveler basic blue 1 during copper superconformal growth. ACS Appl Mater Interfaces 15(40):47628–47639. https://doi.org/10.1021/acsami.3c06567

Lai ZQ et al (2018) Computational analysis and experimental evidence of two typical levelers for acid copper electroplating. Electrochim Acta 273:318–326. https://doi.org/10.1016/j.electacta.2018.04.062

Wang F, Le Y (2020) "Bis-(3-sulfopropyl) disulfide acceleration of copper electrodeposition via molecular dynamics and quantum chemical calculations. Int J Electrochem Sci 15(6):4931–4943. https://doi.org/10.20964/2020.06.11

Jiang J et al (2023) Theoretical calculations and electrochemical investigation of additives in aqueous methanesulfonic acid for lead electrodeposition. Colloids Surf A-Physicochem Eng Aspects 676(132312). https://doi.org/10.1016/j.colsurfa.2023.132312

Lipkowski P, Grabowski SJ, Robinson TL, Leszczynski J (2004) Properties of the C-H•••H dihydrogen bond: an ab initio and topological analysis. J Phys Chem A 108(49):10865–10872. https://doi.org/10.1021/jp048562i

Jenkins S, Morrison I (2000) The chemical character of the intermolecular bonds of seven phases of ice as revealed by ab initio calculation of electron densities. Chem Phys Lett 317(1–2):97–102. https://doi.org/10.1016/s0009-2614(99)01306-8

Acknowledgements

This work was supported by the National Key Research and Development Program of China [No. 2021YFB3400800] and Postdoctoral fellowship of Heilongjiang Province (LBH-Z23156), the fellowship of China Postdoctoral Science Foundation (GZC20233449).

Funding

National Key Research and Development Program of China, 2021YFB3400800.

Author information

Authors and Affiliations

Contributions

Lanchen Li: Writing-original draft, Investigation, Formal analysis, Methodology. Xuesong Peng: Writing- review & editing, Data curation. Jie Jiang: Investigation, Validation. Jinqiu Zhang: Supervision, Modifications. Peixia Yang: Resources. Ruopeng Li and Maozhong An: Funding acquisition, Project administration, Resources.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, L., Peng, X., Jiang, J. et al. Functional additives inhibit crystal growth to achieve low-roughness and high-peel strength of micro-coarsening copper foil. Ionics (2024). https://doi.org/10.1007/s11581-024-05566-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11581-024-05566-6