Abstract

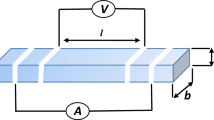

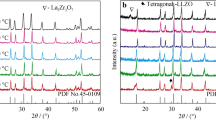

The Nd and Gd co-doped zirconia Zr1–x–yNdxGdyO2–δ (x, y = 0.025, 0.05, 0.075, and 0.10) system of materials were prepared through a modified sol–gel route. Sintering of the samples was conducted using conventional sintering at 1300 °C for 6 h. The prepared materials are characterized by powder X-ray diffraction (P–XRD), scanning electron microscopy with energy dispersive spectroscope (SEM with EDS), Fourier transform infrared (FTIR), Raman, and impedance spectroscopy. The dense electrolyte pellets are produced with co-doping in zirconia. P–XRD confirmed the formation of samples with single phases with stabilized cubic structure even after the sintering of co-doped zirconia samples. SEM and EDS revealed good density in surface microstructure and elemental confirmation in all the compositions. XRD and SEM studies also revealed the highest relative density and small grain size of Zr0.85Nd0.075Gd0.075O2–δ. FTIR disclosed the absorption bands corresponding to the chemical bonds of oxides in the compositions, and the findings are consistent with the P–XRD data. Raman spectroscopy analysis revealed the further phase confirmation of cubic structure. Impedance spectroscopy unveiled the enhanced electrical properties, i.e., enhanced ionic conductivity and small activation energy of NGZ7.5. The enhanced ionic conductivity, i.e., 0.47 × 10−2 S/cm at 550 °C with the stabilized cubic structure of Zr0.85Nd0.075Gd0.075O2–δ sample makes it suitable for solid electrolytes towards intermediate temperature solid oxide fuel cell applications.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

Dresselhaus MS, Thomas IL (2001) Nature 414:332

Brain CH, Steele J (2001) Mater Sci 36:1053

Stambouli AB, Traversa E (2002) Renew Sustain Energy Rev 6:433

Singhal SC (2000) Solid State Ionics 135:305

Minh NQ (2004) Solid State Ionics 174:271

Minh NQ (1993) J Am Ceram Soc 76:536

Badwal SPS (1992) Solid State Ionics 52:23

Raghvendra PS, Singh RK (2013) J Alloys Compd 549:238

Fu Y-P, Chen S-H, Huang J-J (2010) Int J Hydrog Energy 35:745

Anjaneya KC, Nayaka GP, Manjanna J, Govindaraj G, Ganesh KN (2013) J Alloys Compd 578:53

Pikalova EY, Murashkina AA, Maragou VI, Demin AK, Strekalovsky VN, Tsiakaras PE (2011) Int J Hydrog Energy 36:6175

Lakshmi VV, Bauri R, Gandhi AS, Paul S (2011) Int J Hydrog Energy 36:14936

Ji Y, Liu J, Lu Z, Zhao X, He T, Su W (1999) Solid State Ionics 126:277

Lakshmi VV, Bauri R (2011) Solid State Sci 13:1520

Suresh MB, Johnson R (2012) Int J Energy Res 36:1291

ShyamKumar CN, Bauri R (2014) J Phys Chem Solids 75:642

Mahendran R, Manivannan S, Kumaran SS, Vallimanalan A, Murali M, Raj SG, Babu SPK (2019) J Mater Res Technol 8(6):5867

Guo CX, Wang JX, He CR, Wangn WG (2013) Ceram Int 39:9575

Mahato N, Gupta A, Balani K (2012) Nanomater Energy 1:27

Zhigachev AO, Rodaev VV, Zhigacheva DV, Lyskov NV, Shchukina MA (2021) Ceram Int 47:32490

Nakayama S, Tokunaga R, Takata M, Kondo S, Nakajima Y (2021) Open Ceram 6:100136

Kumar CNS, Bauri R, Reddy GS (2020) J Alloys Compd 833:155100

Xing Y-Z, Men Y-N, Feng X, Geng J-H, Zou Z-R, Chen F-H (2022) J Solid State Chem 315:123497

Kumar A, Jaiswal A, Sanbui M, Omar S (2016) Scr Mater 121:10–13

Alizadeh SM, Mohebbi H, Golmohammad M, Sharifi O, Farzaneh F (2023) J Alloys Compd 938:168553

Keˇzionis A, ˇSalkus T, Dudek M, Madej D, Mosiałek M (2024) J Power Sources 591:233846

Mosiałek M, Hanif MB, ˇSalkus T, Keˇzionis A, Kazakeviˇcius E, Orliukas AF, Socha RP, Łasocha W, Dziubaniuk M, Wyrwa J, Gregor M, Motola M (2023) Ceram Int 49:15276–15283

Swamy B, Venkataramana K, Naresh M, Reddy CV (2022) High Technol Lett 28(12):723

Ramesh S, Raju KCJ (2012) Int J Hydrogen Energy 37:10311

Ramesh S, Ng CK, Tan CY, Wong WH, Ching CY, Muchtar A, Somalu MR, Ramesh S, Chandran H, Devaraj P (2016) Ceram Int 42:14469

Salavati-Niasari M, Dadkhah M, Davar F (2009) Inorg Chim Acta 362:3969

Gao H, Liu J, Chen H, Li S, He T, Ji Y, Zhang J (2008) Solid State Ionics 179:1620

Shannon RD (1976) Acta Cryst A 32:751

Venkataramana K, Madhuri C, Madhusudan C, Reddy YS, Bhikshamaiah G, Reddy CV (2018) Ceram Int 44:6300

Ravindranatha K, Venkataramanab K, Madhurib C, Reddy CV (2018) Mater Today: Proc 5:27142–27148

Babar ZUD, Hanif MB, Lin XL, Gao J, Mosiałek M, Li C-X (2024) J Colloid Interface Sci 654:1124–1135

Keˇ zionis A, ˇSalkus T, Dudek M, Madej D, Mosiałek M, Napruszewska BD, Łasocha W, Hanif MB, Motola M (2024) J Power Sources 591:233846

Berlin J, Lekshmy SS, Ganesan V, Thomas PV, Joy K (2014) Thin Solid Films 550:199

Anandan K, Rajesh K, Gayathri K, Sharma SV, Hussain SGM, Rajendran V (2020) Phys E: Low-Dim Syst Nanostruct 124:114342

Yi L, Lao LE (2006) Solid State Ionics 177:159

Zhang Y, Shan X, Jin Z, Wang Y (2011) J Hazard Mater 192:559

Huang W, Qiu H, Zhang Y, Nan L, Gao L, Chen J, Omran M, Chen G (2022) Ceram Int 48:25374

Zeeshan, Rafiuddin (2018) J Adv Res 9:35

Rashad MM, Baioumy HM (2008) J Mater Proc Technol 195:178

Gazzoli D, Mattei G, Valigi M (2007) J Raman Spectrosc 38:824

Basahel SN, Ali TT, Mokhtar M, KN Rao (2015) Nanoscale Res Lett 10:73

Cai J, Raptis C, Raptis YS, Anastassakis E (1995) Phys Rev B 51:201

Wulfman C, Sadoun M, de la Chapelle ML (2010) IRBM 31:257

Venkataramana K, Madhuri C, Madhusudan C, Bhogi A, Srinivas B, Reddy CV (2022) Mater Sci Semicond Process 142:106495

Madhuri C, Venkataramana K, Shanker J, Reddy CV (2020) J Alloys Compd 849:156636

Kwona OH, Jang C, Lee J, Jeong HY, Kwon Y-I, Joo JH, Kim H (2017) Ceram Int 43:8236–8245

Majedi A, Abbasi A, Davar F (2016) J Sol-Gel Sci Technol 77:542–552

Arabaci A (2017) Metall Mater Trans A 48(5):2282–2288

Momin N, Manjanna J, Aruna ST, Kumar SS, Anjaneya KC (2022) Ceram Int 48:35867–35873

Kirkgeçit R, Torun H (2020) Appl Ceram 14(4):314–320

Anirban S, Dutta A (2016) Solid State Ionics 295:48–56

Zhu M, Yi L, Zhou R, Du C, Tian C, Yang J (2024) J Alloys Compd 976:173108

Hanif MB, Rauf S, Mosiałek M, Khan K, Kavaliuk V, Kezionis A, Salkus T, Gurgul J, Medvedev D, Zimowska M, Madej D, Motola M (2023) Int J Hydrogen Energy 48:37532–37549

Hou J, Liu Y, Cheng C, Cheng F, Su T, Ma C, Miao Y, Wang X (2023) Ceram Int 49:37187–37195

Acknowledgements

The author B Swamy thanks the CSIR, New Delhi, India, for financial assistance under the scheme of a CSIR-JRF (NET) fellowship during the research work.

Author information

Authors and Affiliations

Contributions

B Swamy: conceptualization, methodology, investigation, and writing—original draft. Kasarapu Venkataramana: investigation, software, analysis and interpretation of data, validation, draft writing, and correction. Chittimadula Madhuri: investigation, analysis and interpretation of data, data curation, and review and editing. Ashok Bhogi: correction and review and editing. C Vishnuvardhan Reddy: correction, writing—review and editing, and supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Swamy, B., Venkataramana, K., Madhuri, C. et al. Structural and electrical studies of Nd and Gd co-doped zirconia electrolytes for IT-SOFC applications. Ionics 30, 2167–2176 (2024). https://doi.org/10.1007/s11581-024-05448-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-024-05448-x