Abstract

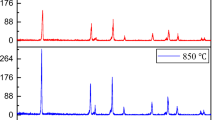

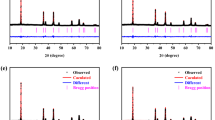

LiNi0.5Mn1.5O4 (LNMO) material is a new generation of high-energy density lithium-ion battery (LIB) cathode material, which has attracted the attention of researchers at home and abroad. Due to the inherent side effects of LNMO materials with the electrolyte at high voltage, Mn dissolution is caused, which hinders its application. The pristine and LiNi0.5−x/2Mn1.5−x/2ErxO4 (x = 0.01, 0.03 and 0.05) were prepared by the microwave-assisted sol–gel method as cathode materials for LIBs. XRD diffraction analysis showed that the lattice parameters of LNMO samples increased after Er doping, which broadened the lithium-ion diffusion channel, and FT-IR showed that LiNi0.5−x/2Mn1.5−x/2ErxO4 (x = 0.01) (LNMO-Er0.01) had the largest disorder degree. Based on electrochemical analysis, LNMO materials doped with an adequate amount of Er was found to have superior cycle stability, high temperature, and rate performances. After 200 charge–discharge cycles, the discharge-specific capacity of LNMO-Er0.01 sample is 118.8 mAh g−1, and the capacity retention rate is 93.8%. In this case, it can provide a capacity of 109.8 mAh g−1 at a high current of 20 C. Furthermore, after 100 cycles at 1 C and 55 ℃, the discharge capacity of the LNMO-Er0.01 sample reached 114.0 mAh g−1 with a capacity retention rate of 92.8%. In summary, the structural stability and electrochemical performance of the LNMO cathode material doped with Er3+ have been significantly improved.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

Huang Y (2022) The discovery of cathode materials for lithium-ion batteries from the view of interdisciplinarity. Interdiscip Mater 1(3):7

Ma J, Hu P, Cui G, Chen L (2016) Surface and interface issues in spinel LiNi0.5Mn1.5O4: insights into a potential cathode material for high energy density lithium ion batteries. Chem Mater 28(11):3578–3606

Yi T-F, Mei J, Zhu Y-R (2016) Key strategies for enhancing the cycling stability and rate capacity of LiNi0.5Mn1.5O4 as high-voltage cathode materials for high power lithium-ion batteries. J Power Sources 316:85–105

Deng Y-F, Zhao S-X, Xu Y-H, Nan C-W (2015) Effect of temperature of Li2O–Al2O3–TiO2–P2O5 solid-state electrolyte coating process on the performance of LiNi0.5Mn1.5O4 cathode materials. J Power Sources 296:261–267

Shin DW, Bridges CA, Huq A, Paranthaman MP, Manthiram A (2012) Role of cation ordering and surface segregation in high-voltage spinel LiMn1.5Ni0.5–xMxO4 (M = Cr, Fe, and Ga) cathodes for lithium-ion batteries. Chem Mater 24(19):3720–3731

Santhanam R, Rambabu B (2010) Research progress in high voltage spinel LiNi0.5Mn1.5O4 material. J Power Sources 195(17):5442–5451

Song J, Shin DW, Lu Y, Amos CD, Manthiram A, Goodenough JB (2012) Role of oxygen vacancies on the performance of Li[Ni0.5–xMn1.5+x]O4 (x = 0, 0.05, and 0.08) spinel cathodes for lithium-ion batteries. Chem Mater 24(15):3101–3109

Wu W, Guo J, Qin X, Bi C, Wang J, Wang L, Liang G (2017) Enhanced electrochemical performances of LiNi0.5Mn1.5O4 spinel in half-cell and full-cell via yttrium doping. J Alloys Compd 721:721–730

Xiao J, Chen X, Sushko PV, Sushko ML, Kovarik L, Feng J, Deng Z, Zheng J, Graff GL, Nie Z, Choi D, Liu J, Zhang J-G, Whittingham MS (2012) High-performance LiNi0.5Mn1.5O4 spinel controlled by Mn3+ concentration and site disorder. Adv Mater 24(16):2109–2116

Kim WK, Han DW, Ryu WH, Lim SJ, Eom JY, Kwon HS (2014) Effects of Cl doping on the structural and electrochemical properties of high voltage LiMn1.5Ni0.5O4 cathode materials for Li-ion batteries. J Alloys Compd 592:48–52

Deng YF, Zhao SX, Xu YH et al (2015) Impact of P-Doped in Spinel LiNi0.5Mn1.5O4 on Degree of Disorder, Grain Morphology, and Electrochemical Performance[J]. Chemistry of Materials: A Publication of the American Chemistry Society 27–22

Gong J, Yan S, Lang Y, Zhang Y, Fu S, Guo J, Wang L, Liang G (2021) Effect of Cr3+ doping on morphology evolution and electrochemical performance of LiNi0.5Mn1.5O4 material for Li-ion battery. J Alloys Compd 859:157885

Gajraj V, Azmi R, Darma MSD, Indris S, Ehrenberg H, Mariappan CR (2021) Correlation between structural, electrical and electrochemical performance of Zn doped high voltage spinel LiNi0.5-xZnxMn1.5O4 porous microspheres as a cathode material for Li-Ion batteries. Ceram Int 47(24):35275–35286

Liu GQ, Zhang LX, Sun L, Wang L (2013) A new strategy to diminish the 4 V voltage plateau of LiNi0.5Mn1.5O4. Mater Res Bull 48(11):4960–4962

Liu MH, Huang HT, Lin CM, Chen JM, Liao SC (2014) Mg gradient-doped LiNi0.5Mn1.5O4 as the cathode material for Li-ion batteries. Electrochim Acta 120:133–139

Sun HY, Kong X, Wang BS, Luo TB, Liu GY (2018) Cu doped LiNi0.5Mn1.5-xCuxO4 (x=0, 0.03, 0.05, 0.10, 0.15) with significant improved electrochemical performance prepared by a modified low temperature solution combustion synthesis method. Ceram Int 44(5):4603–4610

Yoon J, Jeong M, Bae IT, Nam KW, Yoon WS (2017) Zr-doping effect on the capacity retention of LiNi0.5Mn1.5O4-delta cycled between 5.0 and 1.0 V: in situ synchrotron X-ray diffraction study. J Power Sources 368:1–10

Wang H, Xia H, Lai MO, Lu L (2009) Enhancements of rate capability and cyclic performance of spinel LiNi0.5Mn1.5O4 by trace Ru-doping. Electrochem Commun

Zong B, Lang Y, Yan S, Deng Z, Gong J, Guo J, Wang L, Liang G (2020) Influence of Ti doping on microstructure and electrochemical performance of LiNi0.5Mn1.5O4 cathode material for lithium-ion batteries. Mater Today Commun 24:101003

Zeng F, Zhang Y, Shao ZQ (2022) Synthesis and electrochemical performance of Mo-doped LiNi0.5Mn1.5O4 cathode material. Mater Manuf Process 38:197–205

Mo MY, Hui KS, Hong XT, Guo JS, Ye CC, Li AJ, Hu NQ, Huang ZZ, Jiang JH, Liang JZ, Chen HY (2014) Improved cycling and rate performance of Sm-doped LiNi0.5Mn1.5O4 cathode materials for 5 V lithium ion batteries. Appl Surf Sci 290:412–418

Liu S, Zhao H, Tan M, Hu Y, Shu X, Zhang M, Chen B, Liu X (2017) Er-Doped LiNi0.5Mn1.5O4 cathode material with enhanced cycling stability for lithium-ion batteries. Materials 10

Wu W, Guo JL, Qin X, Bi CB, Wang JF, Wang L, Liang GC (2017) Enhanced electrochemical performances of LiNi0.5Mn1.5O4 spinel in half -cell and full -cell via yttrium doping. J Alloys Compd 721:721–730

Ji X, Dai XY, Wu FZ, Jin HX (2022) Liquid-phase integrated surface modification to construct stable interfaces and superior performance of high-voltage LiNi0.5Mn1.5O4 cathode materials. Acs Sustain Chem Eng 10(30):9850–9859

Fujiyama N, Nishibata T, Seki A, Hirata H, Ogawa K (2017) Austenite grain growth simulation considering the solute-drag effect and pinning effect. Technol Adv Mater 18(1):88–95

Ye C, Li A, Chen H, Hui KS, Hu N (2014) Improved cycling and rate performance of Sm-doped LiNi0.5Mn1.5O4 cathode materials for 5 V lithium ion batteries. Appl Surf Sci: J Devoted Prop Interfaces Relat Synth Behav Mater 290(Jan.30):412–418

Liu H, Zhang K-L (2004) The synthesis and cycling behavior of LiErxMn2−xO4 for lithium-ion batteries. Mater Lett 58:3049–3051

Shanshan L, Hongyuan Z, Ming T, Youzuo H, Xiaohui S, Meiling Z, Bing C, Xingquan L (2017) Er-doped LiNi0.5Mn1.5O4 cathode material with enhanced cycling stability for lithium-ion batteries. Materials 10(8):859

Cui X, Zhou X, Liang W, Tuo K, Wang P, Cui X, Zhang L, Li S (2022) Exploring the action mechanism of magnesium in different cations sites for LiNi0.5Mn1.5O4 cathode materials. Mater Today Sustain 17:100105

Mohassel R, Soofivand F, Dawi EA, Shabani-Nooshabadi M, Salavati-Niasari M (2023) ErMnO3/Er2Mn2O7/ZnO/GO multi-component nanocomposite as a promising material for hydrogen storage: facile synthesis and comprehensive investigation of component roles. J Energy Storage 65:107285

Yang LW, Zhitomirsky I (2023) Influence of capping agents on the synthesis of Mn3O4 nanostructures for supercapacitors. ACS Appl Nano Mater 6(6):4428–4436

Amin R, Muralidharan N, Petla RK, Ben Yahia H, Jassim Al-Hail SA, Essehli R, Daniel C, Khaleel MA, Belharouak I (2020) Research advances on cobalt-free cathodes for Li-ion batteries - The high voltage LiMn1.5Ni0.5O4 as an example. J Power Sources 467:228318

Lu Z, Liu Y, Lu X, Wang H, Yang G, Chao Y, Li W, Yin F (2017) An active core-shell nanoscale design for high voltage cathode of lithium storage devices. J Power Sources 360:409–418

Zhong H, He J, Zhang L (2017) Better cycle stability and rate capability of high-voltage LiNi0.5Mn1.5O4 cathode using water soluble binder. Mater Res Bull 93:194–200

Kunduraci M, Al-Sharab JF, Amatucci GG (2006) High-power nanostructured LiMn2-xNixO4 high-voltage lithium-ion battery electrode materials: electrochemical impact of electronic conductivity and morphology. Chem Mater 18(15):3585–3592

Liu RR, Deng X, Liu XR, Yan HJ, Cao AM, Wang D (2014) Facet dependent SEI formation on the LiNi0.5Mn1.5O4cathode identified by in situ single particle atomic force microscopy. Chem Commun 50(99):15756–15759

Kunduraci M, Amatucci GG (2006) Synthesis and characterization of nanostructured 4.7 V Lix Mn1.5Ni0.5O4 spinels for high-power lithium-ion batteries. J Electrochem Soc 153(7):A1345

Li SR, Chen CH, Dahn JR (2013) Studies of LiNi0.5Mn1.5O4 as a positive electrode for Li-ion batteries: M3+ doping (M=Al, Fe, Co and Cr), electrolyte salts and LiNi0.5Mn1.5O4/Li4Ti5O12 cells. J Electrochem Soc 160(11):A2166

Deng Y, Mou J, He L, Xie F, Zheng Q, Xu C, Lin D (2018) A core-shell structured LiNi0.5Mn1.5O4@LiCoO2 cathode material with superior rate capability and cycling performance. Dalton Trans 47(2):367–375

Zong B, Deng Z, Yan S, Lang Y, Gong J, Guo J, Wang L, Liang G (2020) Effects of Si doping on structural and electrochemical performance of LiNi0.5Mn1.5O4 cathode materials for lithium-ion batteries. Powder Technol 364:725–737

Yin C, Bao Z, Tan H, Zhou H, Li J (2019) Metal-organic framework-mediated synthesis of LiNi0.5Mn1.5O4: tuning the Mn3+ content and electrochemical performance by organic ligands. Chem Eng J 372:408–419

Qiao R, Wang Y, Olalde-Velasco P, Li H, Hu Y-S, Yang W (2015) Direct evidence of gradient Mn(II) evolution at charged states in LiNi0.5Mn1.5O4 electrodes with capacity fading. J Power Sources 273:1120–1126

Benedek R, Thackeray MM (2011) Simulation of the surface structure of lithium manganese oxide spinel. Phys Rev B 83(19):195439

Chu C-T, Mondal A, Kosova NV, Lin J-Y (2020) Improved high-temperature cyclability of AlF3 modified spinel LiNi0.5Mn1.5O4 cathode for lithium-ion batteries. Appl Surf Sci 530:147169

Cho J-H, Park J-H, Lee M-H, Song H-K, Lee S-Y (2012) A polymer electrolyte-skinned active material strategy toward high-voltage lithium ion batteries: a polyimide-coated LiNi0.5Mn1.5O4 spinel cathode material case. Energy Environ Sci: EES 5(5):7124–7131

Mukai K (2019) Zero-strain insertion materials for all-solid-state Li-ion batteries. In: Murugan R, Weppner W (eds) Solid Electrolytes for Advanced Applications: Garnets and Competitors. Springer International Publishing, Cham, pp 219–240

Ji X, Dai X, Wu F, Mai Y, Chen H, Gu Y (2021) In situ Sr2+-doped spinel LiNi0.5Mn1.5O4 cathode material for Li-ion batteries with high electrochemical performance and its impact on morphology. Ceram Int 47(22):32043–32052

Casas-Cabanas M, Kim C, Rodriguez-Carvajal J, Cabana J (2016) Atomic defects during ordering transitions in LiNi0.5Mn1.5O4 and their relationship with electrochemical properties. J Mater Chem A 4(21):8255–8262

Chemelewski KR, Manthiram A (2013) Origin of site disorder and oxygen nonstoichiometry in LiMn1.5Ni0.5–xMxO4 (M = Cu and Zn) cathodes with divalent dopant ions. J Phys Chem C 117(24):12465–12471

Yang T, Zhang N, Lang Y, Sun K (2011) Enhanced rate performance of carbon-coated LiNi0.5Mn1.5O4 cathode material for lithium ion batteries. Electrochim Acta 56(11):4058–4064

Wang Y, Peng Q, Yang G, Yang Z, Zhang L, Long H, Huang Y, Lu P (2014) High-stability 5V spinel LiNi0.5Mn1.5O4 sputtered thin film electrodes by modifying with aluminium oxide. Electrochim Acta 136:450–456

Wang X, Wang H, Wen J, Tan Y, Zeng Y (2021) Surface modification of LiMn2O4 cathode with LaCoO3 by a molten salt method for lithium ion batteries. Ceram Int 47(5):6434–6441

Liu GQ, Kuo HT, Liu RS, Shen CH, Shy DS, Xing XK, Chen JM (2010) Study of electrochemical properties of coating ZrO2 on LiCoO2. J Alloy Compd 496(1–2):512–516

Mu J, Zhang L, He R, Li X, Liu Z (2021) Enhancing the electrochemical performance of LiNi0.5Mn1.5O4 cathode material by a conductive LaCoO3 coating. J Alloys Compd 865(1):158629

Funding

This work was supported by the Guizhou Dalong Huicheng New Material Co. Ltd (Grant No. 2018HCXM01).

Author information

Authors and Affiliations

Contributions

Bingbing Huang wrote the main manuscript text,including the acquisition, analysis and interpretation of data; Xiongwen Dong revised it critically for important intellectual content; Minyin Su drafted the work for important intellectual content; Qibin Liu revises the final draft; Min Shen analyzing data; Teng Xu Draw experimental pictures; All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, B., Dong, X., Su, M. et al. Er-doped spinel LiNi0.5Mn1.5O4 as cathode for enhanced electrochemical properties in lithium-ion batteries. Ionics 30, 1871–1883 (2024). https://doi.org/10.1007/s11581-024-05415-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-024-05415-6