Abstract

In the present study, an ammonia complexation-oxidation-homogeneous precipitation-assisted high-temperature solid phase approach was used to constructing evenly connected Li2MnO3 surface on LiNi0.8Co0.1Mn0.09Al0.01O2 (NCMA) cathode materials. The structural stability of NCMA and the cycling performance at high cut-off voltages were greatly improved by the advantages of the high voltage (below 4.5 V) stability of Li2MnO3-based surface. 5%M-NCMA, obtained from Ni0.8Co0.1Mn0.09Al0.01(OH)2 precursors coated with 5 wt % of Mn3O4 uniformly, showed improved electrochemical performance, which shows initial discharge specific capacities of 215.06 and 224.30 mAh g−1 at high voltage ranges of 3.0–4.5 V and 3.0–4.8 V at 0.1 C, respectively. The capacity retention of 5%M-NCMA after 200 cycles at a rate of 1 C rate under the reinforcement of the high voltage stable table interface is 83.89 and 78.09% under 4.5 and 4.8 V, which were enhanced relative by 8.39% and 32.75% relative to the uncoated samples.

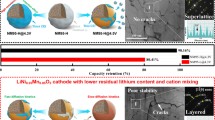

Graphical Abstract

Similar content being viewed by others

References

Li M, Lu J, Chen Z, Amine K (2018) 30 years of lithium-ion batteries. Adv Mater 30:1800561

Zeng X, Zhan C, Lu J, Amine K (2018) Stabilization of a high-capacity and high-power nickel-based cathode for li-ion batteries. Chem 4:690–704

Choi D, Kang J, Han B (2019) Unexpectedly high energy density of a Li-ion battery by oxygen redox in LiNiO2 cathode: first-principles study. Electrochim Acta 294:166–172

Li X, Zhao R, Fu Y, Manthiram A (2021) Nitrate additives for lithium batteries: mechanisms, applications, and prospects. eScience 1:108–123

Schweidler S, de Biasi L, Garcia G, Mazilkin A, Hartmann P, Brezesinski T, Janek J (2019) Investigation into mechanical degradation and fatigue of high-Ni NCM cathode material: a long-term cycling study of full cells. ACS Appl Energy Mater 2:7375–7384

Wang L, Qiu J, Wang X, Chen L, Cao G, Wang J, Zhang H, He X (2022) Insights for understanding multiscale degradation of LiFePO4 cathodes. eScience 2:125–137

Dong P, Wang D, Yao Y, Li X, Zhang Y, Ru J, Ren T (2017) Stabilizing interface layer of LiNi0.5Co0.2Mn0.3O2 cathode materials under high voltage using p-toluenesulfonyl isocyanate as film forming additive. J Power Sourc 344:111–118

Kim UH, Jun DW, Park KJ, Zhang Q, Kaghazchi P, Aurbach D, Major DT, Goobes G, Dixit M, Leifer N, Wang CM, Yan P, Ahn D, Kim KH, Yoon CS, Sun YK (2018) Pushing the limit of layered transition metal oxide cathodes for high-energy density rechargeable Li ion batteries. Energy Environ Sci 11:1271–1279

Xu X, Xiang L, Wang L, Jian J, Du C, He X, Huo H, Cheng X, Yin G (2019) Progressive concentration gradient nickel-rich oxide cathode material for high-energy and long-life lithium-ion batteries. J Mater Chem 7:7728–7735

Ni L, Guo R, Fang S, Chen J, Gao J, Mei Y, Zhang S, Deng W, Zou G, Hou H, Ji X (2022) Crack-free single-crystalline Co-free Ni-rich LiNi0.95Mn0.05O2 layered cathode. Science 2:116–124

Liu H, Wolfman M, Karki K, Yu Y-S, Stach EA, Cabana J, Chapman KW, Chupas PJ (2017) Intergranular cracking as a major cause of long-term capacity fading of layered cathodes. Nano Lett 17:3452–3457

Hwang SK, Park TJ, Kim KL, Cho SM, Jeong BJ, Park C (2014) Organic one-transistor-type nonvolatile memory gated with thin ionic liquid-polymer film for low voltage operation. ACS Appl Mater Interfaces 6:20179–20187

Hua W, Yang X, Casati NPM, Liu L, Wang S, Baran V, Knapp M, Ehrenberg H, Indris S (2022) Probing thermally-induced structural evolution during the synthesis of layered Li-, Na-, or K-containing 3d transition-metal oxides. eScience 2:183–191

Kondrakov AO, Schmidt A, Xu J, Geßwein H, Mönig R, Hartmann P, Sommer H, Brezesinski T, Janek J (2017) Anisotropic lattice strain and mechanical degradation of high- and low-nickel NCM cathode materials for li-ion batteries. J Phys Chem C 121:3286–3294

Mao Y, Wang X, Xia S, Zhang K, Wei C, Bak S, Shadike Z, Liu X, Yang Y, Xu R, Pianetta P, Ermon S, Stavitski E, Zhao K, Xu Z, Lin F, Yang X-Q, Hu E, Liu Y (2019) High-voltage charging-induced strain, heterogeneity, and micro-cracks in secondary particles of a nickel-rich layered cathode material. Adv Func Mater 29:1900247

Hou P, Yin J, Ding M, Huang J, Xu X (2017) Surface/interfacial structure and chemistry of high-energy nickel-rich layered oxide cathodes: advances and perspectives. Small 13:1701802

Lin F, Markus IM, Nordlund D, Weng T-C, Asta MD, Xin HL, Doeff MM (2014) Surface reconstruction and chemical evolution of stoichiometric layered cathode materials for lithium-ion batteries. Nat Commun 5:3529

Shu Y, Xie Y, Yan WC, Meng S, Sun DY, Jin YC, Xiang L (2020) Tuning the ratio of Al2O3 to LiAlO2 in the composite coating layer for high performance LiNi0.5Mn1.5O4 materials. Ceram Int 46:14840–14846

Jo SJ, Hwang DY, Lee SH (2021) Use of zirconium dual-modification on the LiNi0.8Co0.1Mn0.1O2 cathode for improved electrochemical performances of lithium-ion batteries. ACS Appl Energy Mater 4:3693–3700

Li YY, Li XF, Hu JH, Liu W, Sari HMK, Li DJ, Sun Q, Kou L, Tian ZY, Shao L, Zhang C, Zhang JJ, Sun XL (2020) ZnO Interface modified LiNi0.6Co0.2Mn0.2O2 toward boosting lithium storage. Energy Environ Mater 3:522–528

Khollari MAR, Azar MK, Esmaeili M, Malekpour N, Hosseini-Hosseinabad SM, Moakhar RS, Dolati A, Ramakrishna S (2021) Electrochemical Performance and elevated temperature properties of the TiO2-coated Li[Ni0.8Co0.1Mn0.1]O2 cathode material for high-safety Li-ion batteries. ACS Appl Energy Mater 4:5304–5315

Mwizerwa JP, Liu CY, Xu K, Zhao N, Li YD, Chen ZW, Shen J (2022) Three-dimensional printed lithium iron phosphate coated with magnesium oxide cathode with improved areal capacity and ultralong cycling stability for high performance lithium-ion batteries. J Colloid Interface Sci 623:168–181

Hu G, Zhang M, Wu L, Peng Z, Du K, Cao Y (2016) High-conductive AZO nanoparticles decorated Ni-rich cathode material with enhanced electrochemical performance. ACS Appl Mater Interfaces 8:33546–33552

Du Y-H, Sheng H, Meng X-H, Zhang X-D, Zou Y-G, Liang J-Y, Fan M, Wang F, Tang J, Cao F-F, Shi J-L, Cao X-F, Guo Y-G (2022) Chemically converting residual lithium to a composite coating layer to enhance the rate capability and stability of single-crystalline Ni-rich cathodes. Nano Energy 94:106901

Yu H, He XQ, Liang XH (2022) AlF3-Al2O3 ALD thin-film-coated Li1.2Mn0.54Co0.13Ni0.13O2 particles for lithium-ion batteries: long-term protection. ACS Appl Mater Interf 14:3991–4003

Yan P, Zheng J, Liu J, Wang B, Cheng X, Zhang Y, Sun X, Wang C, Zhang J-G (2018) Tailoring grain boundary structures and chemistry of Ni-rich layered cathodes for enhanced cycle stability of lithium-ion batteries, Nature. Energy 3:600–605

Tan S, Shadike Z, Li JZ, Wang XL, Yang Y, Lin RQ, Cresce A, Hu JT, Hunt A, Waluyo I, Ma L, Monaco F, Cloetens P, Xiao J, Liu YJ, Yang XQ, Xu K, Hu EY (2022) Additive engineering for robust interphases to stabilize high-Ni layered structures at ultra-high voltage of 4.8 V, Nature. Energy 7:484–494

Mao G, Xiao F, Zeng L, Tang R, Li J, Zhou Q, Wang Y (2022) Improvement of cycle performance of the high nickel cathode material LiNi0.88Co0.07Al0.05O2 for lithium-ion batteries by the spray drying of V2O5. J Alloys Compd 892(2022):162161

Yu HF, Wang SL, Hu YJ, He GJ, Bao LQ, Parkin IP, Jiang H (2022) Lithium-conductive LiNbO3 coated high-voltage LiNi0.5Co0.2Mn0.3O2 cathode with enhanced rate and cyclability. Green Energy Environ 7:266–274

Li X, Zhao C, He J, Li Y, Wang Y, Liu L, Huang J, Li C, Wang D, Duan J, Zhang Y (2022) Removing lithium residues via H3BO3 washing and concurrent in-situ formation of a lithium reactive coating on Ni-rich cathode materials toward enhanced electrochemical performance. Electrochim Acta 406:139879

Johnson CS, Li N, Vaughey JT, Hackney SA, Thackeray MM (2005) Lithium-manganese oxide electrodes with layered-spinel composite structures xLi2MnO3·(1−x)Li1+yMn2−yO4 (0<x<1, 0⩽y⩽0.33) for lithium batteries. Electrochem Commun 7(2005):528–536

Zhu Y, Luo X, Xu M, Zhang L, Yu L, Fan W, Li W (2016) Failure mechanism of layered lithium-rich oxide/graphite cell and its solution by using electrolyte additive. J Power Sources 317:65–73

Wang W, Hu G, Peng Z, Du K, Cao Y, Duan J (2018) Nano-sized over-lithiated oxide by a mechano-chemical activation-assisted microwave technique as cathode material for lithium ion batteries and its electrochemical performance. Ceram Int 44:1425–1431

Guerrini N, Jin L, Lozano JG, Luo K, Sobkowiak A, Tsuruta K, Massel F, Duda L-C, Roberts MR, Bruce PG (2020) Charging mechanism of Li2MnO3. Chem Mater 32:3733–3740

Yang J, Hou M, Haller S, Wang Y, Wang C, Xia Y (2016) Improving the cycling performance of the layered Ni-rich oxide cathode by introducing low-content Li2MnO3. Electrochim Acta 189:101–110

Zhao J, Wang H, Xie Z, Ellis S, Kuai X, Guo J, Zhu X, Wang Y, Gao L (2016) Tailorable electrochemical performance of spinel cathode materials via in-situ integrating a layered Li2MnO3 phase for lithium-ion batteries. J Power Sources 333:43–52

Huang X, Zhu W, Yao J, Bu L, Li X, Tian K, Lu H, Quan C, Xu S, Xu K, Jiang Z, Zhang X, Gao L, Zhao J (2020) Suppressing structural degradation of Ni-rich cathode materials towards improved cycling stability enabled by a Li2MnO3 coating. J Mater Chem A 8:17429–17441

Zhu J, Li Y, Xue L, Chen Y, Lei T, Deng S, Cao G (2019) Enhanced electrochemical performance of Li3PO4 modified Li[Ni0.8Co0.1Mn0.1]O2 cathode material via lithium-reactive coating. J Alloys Compd 773:112–120

Zhang Y, Wang ZB, Yu FD, Que LF, Wang MJ, Xia YF, Xue Y, Wu J (2017) Studies on stability and capacity for long-life cycle performance of Li(Ni0.5Co0.2Mn0.3)O2 by Mo modification for lithium-ion battery. J Power Sourc 358:1–12

Sun Y-K, Myung S-T, Yoon CS, Kim D-W (2009) Improvement of high voltage cycling performances of Li[Ni1/3Co1/3Mn1/3]O2 at 55 °C by a (NH4)3AlF6 coating. Electrochem Solid-State Lett 12:A163

Funding

This work was supported by the Key Research and Development Program of Yunnan Province (202103AA080019), the Major Science and Technology Projects of Yunnan Province (202202AG050003), the Natural Science Foundation of China (52162030), the Scientific Research Fund of High-end Talents Introduction of Kunming University of Science and Technology (KKKP201752027), and the Yunnan Thousand Talents Program for Young Talents (KKS2202052001).

Author information

Authors and Affiliations

Contributions

L.D.: writing—original draft and data curation. Y.C.: project administration, conceptualization, and investigation. X.Y.: visualization. X. L.: editing. C.Z.: validation. J.H.: editing. P.D.: editing. Y.Z.: editing. X.W.: editing. D.W.: conceptualization, writing—review and editing. J.D.: supervision and resources.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deng, L., Cao, Y., Yang, X. et al. Suppressing interfacial structure failure of Ni-rich cathode materials under high work voltage towards improved cycling stability enabled via Li2MnO3-based surface construction. Ionics 30, 1959–1970 (2024). https://doi.org/10.1007/s11581-024-05397-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-024-05397-5