Abstract

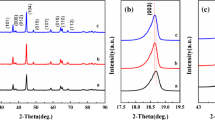

Ni-rich cathode materials, such as Li[Ni1−x−yCoxMny]O2 (NCM) and Li[Ni1−x−yCoxAly]O2 (NCA), are attracting increasing attention in the automobile industry owing to their high reversible capacities and high operating voltages (up to 3.6 V vs. Li/Li+). In this study, a simple dry doping method was employed to fabricate a quaternary Ni-rich cathode material Li(Ni0.9Co0.06Mn0.04)1−xAlxO2 (NCMA, 0 ≤ x ≤ 0.065), wherein inactive Al was doped to improve the electrochemical performance and thermal stability of the base material, NCM. Although Al decreased the capacity and initial efficiency of the material owing to its inactive nature, it enhanced the rate performance by increasing the spacing of the Li slabs as well as the structural stability to improve the cycling performance and thermal stability. The capacity retention of Li(Ni0.9Co0.06Mn0.04)0.95Al0.050O2 increased to 95.04% (3.0–4.3 V, 0.5 C, 25 ℃) and 94.21% (3.0–4.3 V, 0.5 C, 45 ℃) after 100 cycles.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Miller JF, Howell D (2013) The EV everywhere grand challenge. World Electric Veh J 6(4):1008–1013 (https://www.mdpi.com/2032-6653/6/4/1008)

Luo Y-H, Wei H-X, Tang L-B, Huang Y-D, Wang Z-Y, He Z-J et al (2022) Nickel-rich and cobalt-free layered oxide cathode materials for lithium ion batteries. Energy Storage Mater 50:274–307. https://doi.org/10.1016/j.ensm.2022.05.019

Wei HX, Tang LB, Huang YD, Wang ZY, Luo YH, He ZJ et al (2021) Comprehensive understanding of Li/Ni intermixing in layered transition metal oxides. Mater Today (51-):51. https://doi.org/10.1016/j.mattod.2021.09.013

Ryu H-H, Park N-Y, Noh T-C, Kang G-C, Maglia F, Kim S-J et al (2020) Microstrain alleviation in high-energy Ni-rich NCMA cathode for long battery life. ACS Energy Lett 6(1):216–223. https://doi.org/10.1021/acsenergylett.0c02281

Min K, Kim K, Jung C, Seo S-W, Song YY, Lee HS et al (2016) A comparative study of structural changes in lithium nickel cobalt manganese oxide as a function of Ni content during delithiation process. J Power Sources 315:111–119. https://doi.org/10.1016/j.jpowsour.2016.03.017

Bak SM, Hu E, Zhou Y, Yu X, Senanayake SD, Cho SJ et al (2014) Structural changes and thermal stability of charged LiNixMnyCozO2 cathode materials studied by combined in situ time-resolved XRD and mass spectroscopy. ACS Appl Mater Interfaces 6(24):22594–22601. https://doi.org/10.1021/am506712c

Luo Y-H, Pan Q-I, Wei H-X, Huang Y-D, Tang L-B, Wang Z-Y et al (2022) Towards Ni-rich layered oxides cathodes with low Li/Ni intermixing by mild molten-salt ion exchange for lithium-ion batteries. Nano Energy 102:107626. https://doi.org/10.1016/j.nanoen.2022.107626

Huang Y-D, Wei H-X, Li P-Y, Luo Y-H, Wen Q, Le D-H et al (2022) Enhancing structure and cycling stability of Ni-rich layered oxide cathodes at elevated temperatures via dual-function surface modification. J Energy Chem 75:301–309. https://doi.org/10.1016/j.jechem.2022.08.010

Wang L, Liu G, Wang R, Wang X, Wang L, Yao Z et al (n.d.) Regulating surface oxygen activity by perovskite coating stabilized ultrahigh-nickel layered oxide cathodes. Adv Mater n/a(n/a):2209483. https://doi.org/10.1002/adma.202209483

Fan X-M, Huang Y-D, Wei H-X, Tang L-B, He Z-J, Yan C et al (2022) Surface modification engineering enabling 4.6 V Single-crystalline Ni-rich cathode with superior long-term cyclability. Adv Funct Mater 32(6):2109421. https://doi.org/10.1002/adfm.202109421

He T, Lu Y, Su Y, Bao L, Tan J, Chen L et al (2018) Sufficient utilization of zirconium ions to improve the structure and surface properties of nickel-rich cathode materials for lithium-ion batteries. Chemsuschem 11(10):1639–1648. https://doi.org/10.1002/cssc.201702451

Liu H, Li J, Zhang Z, Gong Z, Yang Y (2004) Structural, electrochemical and thermal properties of LiNi0.8−yTiyCo0.2O2 as cathode materials for lithium ion battery. Electrochimica Acta 49(7):1151–1159. https://doi.org/10.1016/j.electacta.2003.11.001

Cai Z, Ma Y, Huang X, Yan X, Yu Z, Zhang S et al (2020) High electrochemical stability Al-doped spinel LiMn2O4 cathode material for Li-ion batteries. J Energy Storage 27:101036. https://doi.org/10.1016/j.est.2019.101036

Xia S, Huang W, Shen X, Liu J, Cheng F, Liu J-J et al (2020) Rearrangement on surface structures by boride to enhanced cycle stability for LiNi0.80Co0.15Al0.05O2 cathode in lithium ion batteries. J Energy Chem 45:110–118. https://doi.org/10.1016/j.jechem.2019.09.023

Liu Q, Su X, Lei D, Qin Y, Wen J, Guo F et al (2018) Approaching the capacity limit of lithium cobalt oxide in lithium ion batteries via lanthanum and aluminium doping. Nat Energy 3(11):936–943. https://doi.org/10.1038/s41560-018-0180-6

Xie Q, Li W, Manthiram A (2019) A Mg-doped high-nickel layered oxide cathode enabling safer, high-energy-density Li-ion batteries. Chem Mater 31(3):938–946. https://doi.org/10.1021/acs.chemmater.8b03900

Li P-Y, Huang Y-D, Tang L-B, Wei H-X, Fu H, He Z-J et al (2022) W-doped LiNi1/3Co1/3Mn1/3O2 with excellent high-rate performance synthesized via hydrothermal lithiation. J Electrochem Soc 169(5):050509. https://doi.org/10.1149/1945-7111/ac653d

Kim U-H, Kuo L-Y, Kaghazchi P, Yoon CS, Sun Y-K (2019) Quaternary layered Ni-rich NCMA cathode for lithium-ion batteries. ACS Energy Lett 4(2):576–582. https://doi.org/10.1021/acsenergylett.8b02499

Li, G. (2018). The preparation and properties research of lithium-rich Li[Li0.2Mn0.54Ni0.13Co0.13]O2 battery cathode materials. Int J Electrochem Sci, 7321–7334. https://doi.org/10.20964/2018.08.08

KookjinHeo J-SL, Kim H-S, Kim M-Y, Jeong H, Kim J, Lim J (2018) Ionic conductor-LiNi0.8Co0.1Mn0.1O2 composite synthesized by simultaneous co-precipitation for use in lithium ion batteries. J Electrochem Soc 165(13):A2955–A2960. https://doi.org/10.1149/2.0201813jes

Cao G, Zhu J, Li Y, Zhou Y, Jin Z, Xu B et al (2020) Synthesis of a fine LiNi0.88Co0.09Al0.03O2 cathode material for lithium-ion batteries via a solvothermal route and its improved high-temperature cyclic performance. RSC Adv 10(17):9917–9923. https://doi.org/10.1039/c9ra08450a

Cobra PF, Gomes BF, Mitre CIN, Barbosa LL, Marconcini LV, Colnago LA (2015) Measuring the solubility product constant of paramagnetic cations using time-domain nuclear magnetic resonance relaxometry. Microchem J 121:14–17. https://doi.org/10.1016/j.microc.2015.02.002

Yang X, Tang Y, Shang G, Wu J, Lai Y, Li J et al (2019) Enhanced cyclability and high-rate capability of LiNi0.88Co0.095Mn0.025O2 cathodes by homogeneous Al3+ doping. ACS Appl Mater Interfaces 11(35):32015–32024. https://doi.org/10.1021/acsami.9b10558

Zheng J, Kan WH, Manthiram A (2015) Role of Mn content on the electrochemical properties of nickel-rich layered LiNi0.8-xCo0.1Mn0.1+xO2 (0.0 ≤ x ≤ 0.08) cathodes for lithium-ion batteries. ACS Appl Mater Interfaces 7(12):6926–34. https://doi.org/10.1021/acsami.5b00788

Xie H, Du K, Hu G, Peng Z, Cao Y (2016) The role of sodium in LiNi0.8Co0.15Al0.05O2 cathode material and its electrochemical behaviors. J Phys Chem C 120(6):3235–3241. https://doi.org/10.1021/acs.jpcc.5b12407

Wang F, Zhang Y, Zou J, Liu W, Chen Y (2013) The structural mechanism of the improved electrochemical performances resulted from sintering atmosphere for LiNi0.5Co0.2Mn0.3O2 cathode material. J Alloy Compd 558:172–178. https://doi.org/10.1016/j.jallcom.2013.01.091

Jang B-C, Son J-T (2016) Structural characterization of new composition core–shell Li[(Ni0.88Co0.07Al0.05)x(Ni0.55Co0.2Mn02Al0.05)y]O2 spherical particles as a cathode material for lithium-ion batteries. J Nanosci Nanotechnol 16(10):10681–10688. https://doi.org/10.1166/jnn.2016.13218

Zhou K, Xie Q, Li B, Manthiram A (2021) An in-depth understanding of the effect of aluminum doping in high-nickel cathodes for lithium-ion batteries. Energy Storage Mater 34:229–240. https://doi.org/10.1016/j.ensm.2020.09.015

Ryu H-H, Park K-J, Yoon CS, Sun Y-K (2018) Capacity fading of Ni-rich Li[NixCoyMn1–x–y]O2 (0.6 ≤ x ≤ 0.95) cathodes for high-energy-density lithium-ion batteries: bulk or surface degradation? Chem Mater 30(3):1155–1163. https://doi.org/10.1021/acs.chemmater.7b05269

Wang S, Zhu J, Li Y, Cao G, Chen Y, Zhang D et al (2021) Role of Al on the electrochemical performances of quaternary nickel-rich cathode LiNi0.8Co0.1Mn0.1AlO2 (0 ≤ x ≤ 0.06) for lithium-ion batteries. J Electroanal Chem 888:115200. https://doi.org/10.1016/j.jelechem.2021.115200

Shao ZC, Guo J, Zhao Z, Xia J, Ma M, Zhang Y (2015) Preparation and properties of Al2O3-doping LiNi1/3Co1/3Mn1/3O2 cathode materials. Mater Manuf Process 31(8):1004–1008. https://doi.org/10.1080/10426914.2015.1117618

Zhang C, Wan J, Li Y, Zheng S, Zhou K, Wang D et al (2020) Restraining the polarization increase of Ni-rich and low-Co cathodes upon cycling by Al-doping. J Mater Chem A 8(14):6893–6901. https://doi.org/10.1039/d0ta00260g

Funding

This work was supported by the Ningbo Science and Technology Innovation 2025 Program (2020Z042).

Author information

Authors and Affiliations

Contributions

Jianxiong Lin: methodology, formal analysis. Xinyu Lian: writing—original draft, data curation, software. Xin Wang: English revision. Yangzhou Ma: validation. Liang Fang: supervision. Xinkun Suo: conceptualization, methodology, writing—review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lin, J., Lian, X., Wang, X. et al. Effects of Al content on the electrochemical performance and thermal stability of Li(Ni0.9Co0.06Mn0.04)1−xAlxO2 cathode materials for Li-ion batteries. Ionics 29, 2153–2162 (2023). https://doi.org/10.1007/s11581-023-04929-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-023-04929-9