Abstract

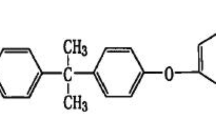

In this paper, a gel polymer electrolyte based on sulfonated polyetherimide (SPEI)/polyetherimide (PEI) blending separator has been fabricated through non-solvent-induced phase separation (NIPS) method. The performance of the SPEI/PEI blending separator is investigated through the morphology and electrochemical analysis. The addition of SPEI polymer has great effect on the morphology of separator’s top and bottom surface. When the SPEI mass ratio increases, the SPEI/PEI blending separator shows high porosity (up to 72.80%), ion conductivity (up to 2.63 mS cm−1), and low tensile strength (down to 7.98 MPa). The discharge specific capacity, capacity retention rate, and average capacity attenuation rate of lithium-sulfur battery using SPEI-2 (separator with the weight ratio of SPEI/PEI = 2:8) are 736.1 mAh g−1, 57.2%, and 0.21% after 200 cycles, respectively. The result shows that the SPEI/PEI blending separator has lower capacity decays compared with SPEI-0 (separator with the weight ratio of SPEI/PEI = 0:10) and the commercial Celgard 2320 separator, which indicates that the existence of sulfonic acid group is conducive to the stability of the lithium-sulfur battery cycle. Therefore, it is concluded that the SPEI/PEI blending separator prepared by NIPS method is a potential separator for high-performance rechargeable lithium-sulfur battery.

Similar content being viewed by others

References

Jiang SF, Zhang ZA, Qu YH, Wang XW, Li Q, Lai YQ, Li J (2014) Activated carbon aerogels with high bimodal porosity for lithium/sulfur batteries. J Solid State Electrochem 18:545–551

Ling M, Yan WJ, Kawase A, Zhao H, Fu YB, Battaglia VS, Liu G (2017) Electrostatic polysulfides confinement to inhibit redox shuttle process in the lithium sulfur batteries. ACS Appl Mater Inter 9:451–469

Barchasz C, Leprêtre JC, Alloin F (2012) New insights into the limiting parameters of the Li/S rechargeable cell. J Power Sources 199:322–330

Yeon SH, Jung KN, Yoon S, Shin KH, Jin CS, Kim Y (2013) Improved electrochemical performances of sulfur-microporous carbon; composite electrode for Li/S battery. J. Appl. Electrochem 43:245–252

Wang C, Wang XS, Yang Y, Kushima A, Chen JT, Huang YH, Li J (2015) Slurryless Li2S/reduced graphene oxide cathode paper for high-performance lithium sulfur battery. Nano Lett 15:1796–1802

Tao R, Bi XX, Li S, Yao Y, Wu F, Wang Q, Zhang CZ, Lu J (2017) Kinetics tuning the electrochemistry of lithium dendrites formation in lithium batteries through electrolytes. ACS Appl Mater Inter 9:7003–7008

Tang W, Zhu YS, Hou YY (2013) Aqueous rechargeable lithium batteries as an energy storage system of superfast charging. Energy Environ Sci 6:2093–2104

Xiao LF, Cao YL, Xiao J, Schwenzer B (2012) A soft approach to encapsulate sulfur: polyaniline nanotubes for lithium-sulfur batteries with long cycle life. Adv Mater 24:1176–1181

Koenhen DM, Mulder MHV, Smolders CA (2010) Phase separation phenomena during the formation of asymmetric membranes. J Appl Polym Sci 21:199–215

Manthiram A, Fu Y, Chung S (2014) Rechargeable lithium-sulfur batteries. Chem Rev 114:11751–11787

Li J, Huang YD, Zhang S, Jia W, Wang XC, Guo Y, Jia DZ, Wang LS (2017) Decoration of silica nanoparticles on polypropylene separator for lithium-sulfur batteries. ACS Appl Mater Inter 9:7499–7504

Winkler H (2003) Microstructure of PE-separators. J Power Sources 113:396–399

Wang Y, Jiang L, Matsuura T, Chung T, Goh SH (2008) Investigation of the fundamental differences between polyamide-imide (PAI) and polyetherimide (PEI) membranes for isopropanol dehydration via pervaporation. J Membr Sci 318:217–226

Bakeri G, Matsuura T, Ismail AF, DashtArzhandi MR (2015) Porous PES and PEI hollow fiber membranes in a gas-liquid contacting process—a comparative study. J Membr Sci 475:57–64

Han RL, Zeng JH, Wang YQ, Chang QB, Zhang XZ, Zhou JE (2014) Preparation and application of positively charged quaternized chitosan/PEI composite nanofiltration membranes. Water Treat 52:5790–5795

Gendi AE, Favre E, Roizard D (2018) Asymmetric polyetherimide membranes (PEI) for nanofiltration treatment. Eur Polym J 105:204–216

Zuo PJ, Hua JF, He MX, Zhang H, Qian ZY, Ma YL, Du CL, Cheng XQ, Gao YZ, Yin GP (2017) Facilitating the redox reaction of polysulfides by an electrocatalytic layer-modified separator for lithium-sulfur batteries. J Mater Chem A 5:452–466

Hashemi AB, Kasiri G, Mantia FL (2017) The effect of polyethyleneimine as an electrolyte additive on zinc electrodeposition mechanism in aqueous zinc-ion batteries. Electrochim Acta 258:703–708

Salleh WNW, Ismail AF (2013) Effect of stabilization condition on PEI/PVP-based carbon hollow fiber membranes properties. Sep Sci Technol 48:1030–1039

Chae C, Kim KW, Lee D, Moon J, Choi Y, Lee S, Choi S, Jeong S (2016) Polyethyleneimine-mediated electrostatic assembly of MnO2 nanorods on graphene oxides for use as anodes in lithium-ion batteries. ACS Appl Mater Inter 8:11499–11506

Peled E, Sternberg Y, Gorenshtein A, Lavi Y (1989) Lithium-sulfur battery: evaluation of dioxolane-based electrolytes. Cheminform 20:24–35

Zhu JD, Yanilmaz M, Fu K (2016) Understanding glass fiber membrane used as a novel separator for lithium-sulfur batteries. J Membr Sci 504:89–96

Saito Y, Kataoka H, Quartarone E, Mustarelli P (2002) Carrier migration mechanism of physically cross-linked polymer gel electrolytes based on PVDF membranes. J Phys Chem B 106:7200–7204

Zhu JD, Chen C, Lu Y, Zang J, Jiang MJ, Kim D, Zhang XW (2016) Highly porous polyacrylonitrile/graphene oxide membrane separator exhibiting excellent anti-self-discharge feature for high-performance lithium-sulfur batteries. Carbon 101:272–280

Song A, Huang Y, Zhong XP, Cao HJ, Liu B, Lin YH, Wang MS, Li X (2018) Novel lignocellulose based gel polymer electrolyte with higher comprehensive performances for rechargeable lithium-sulfur battery. J Membr Sci 556:203–213

Zhang ZY, Lai YQ, Zhang ZA (2014) Al2O3-coated porous separator for enhanced electrochemical performance of lithium sulfur batteries. Electrochim Acta 129:55–61

Huguenin F, Santos D, Bassi A, Nart FC, Oliveira ON (2004) Charge storage capability in nanoarchitectures of V2O5/chitosan/poly(ethylene oxide) produced using the layer-by-layer technique. Adv Funct Mater 14:985–991

Chen GP, Song X, Wang SQ, Wang Y, Gao T, Ding LX, Wang HH (2018) A multifunctional separator modified with cobalt and nitrogen co-doped porous carbon nanofibers for Li-S batteries. J Membr Sci 548:247–253

Bai SY, Liu XZ, Zhu K, Wu SC, Zhou H (2016) Metal–organic framework-based separator for lithium–sulfur batteries. Nat Energy 1:16094

Dibden JW, Smith JW, Zhou N (2016) Predicting the composition and formation of solid products in lithium-sulfur batteries by using an experimental phase separator. Chem Commun 52:12885–12892

Li J, Niu XH, Song JF, Li YM, Li XM, Hao WJ, Fang JH, He T (2019) Harvesting vapor by hygroscopic acid to create pore: morphology, crystallinity and performance of poly (ether ether ketone) lithium ion battery separator. J Membr Sci 577:1–11

Ruiz-Colón E, Suleiman D (2019) Normalized and separation efficiency of phosphonated graphene oxide and sulfonated poly(styrene-isobutylene-styrene) composite membranes. MRS Adv 4:231–240

Dong X, Aljumaily A, Escobar IC (2018) Investigation of the use of a bio-derived solvent for non-solvent-induced phase separation (NIPS) fabrication of polysulfone membranes. Membr 8:2077–2100

Wu X, Fan LS, Qiu Y, Wang MX, Cheng JH, Guan B, Guo ZK, Zhang NQ, Sun KN (2018) Growth of ionic selectivity Prussian blue modified Celgard separator for high performance lithium sulfur battery. ChemSusChem 8:71–78

Huang YG, Zheng TT, Zhang K, She XJ, Xu H, Fang Z, Xie KY (2018) Facile fabrication of permselective g-C3N4 separator for improve lithium-sulfur batteries. Electrochim Acta 272:60–67

Lu Y, Gu S, Guo J, Rui K, Chen CH, Zhang SP, Jin J, Yang JH, Wen ZY (2017) Sulfonic groups originated dual-functional interlayer for high performance lithium-sulfur battery. ACS Appl Mater Inter 9:14878–14888

Kim SH, Yeon JS, Kim R, Choi KM, Park HS (2018) A functional separator coated with sulfonated metal-organic framework/Nafion hybrids for Li-S batteries. J Mater Chem A 6:24971–24978

Liu JQ, Zhu FF, Zhao HJ, Li J, Li QH, Xi Y, Liu M, Wang C (2019) Preparation and performance of porous polyetherimide(PEI)/Al2O3 separator for enhanced lithium-sulfur battery. ChemElectroChem 6:2883–2890

Song SL, Shi L, Lu SY, Pang YC, Wang YK, Zhu M, Ding DW, Ding SJ (2018) A new polysulfide blocker-poly(acrylic acid) modified separator for improved performance of lithium-sulfur battery. J Membr Sci 563:277–283

Cheng WJ, Chang SJ, Cho CS, Li CC (2018) Poly(4-styrene sulfonic acid) to disperse graphene for applications in lithium-sulfur batteries. ChemElectroChem 5:3835–3840

Liao C, Guo BK, Sun XG, Dai S (2015) Synergistic effects of mixing sulfone and ionic liquid as safe electrolytes for lithium sulfur batteries. ChemSusChem 8:353–360

Funding

The authors would like to give our sincere gratitude to the support by National Key R&D Program of China (Grant No. 2018YFB0104200), Special Funds for the Construction of Innovative Province of Hunan (Grant No. 2020GK2056), Natural Science Foundation of Hunan Province (Grant No. 2020JJ4717), and the Open-End Fund for the Valuable and Precision Instruments of Central South University (Grant No. CSUZC202030).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Hong, Z., Zhu, F. et al. Preparation and performance of SPEI/PEI blending separator for enhanced lithium-sulfur battery. Ionics 27, 4749–4759 (2021). https://doi.org/10.1007/s11581-021-04189-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-021-04189-5