Abstract

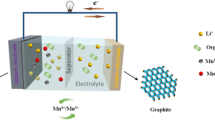

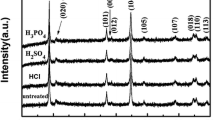

Under the premise of the freeze-drying method, the influence of the calcination temperature on the performance of the LiNi0.5Mn1.5O4 cathode material was explored. After determining the calcination temperature, the effect of calcination time on the LiNi0.5Mn1.5O4 cathode material was further studied. XRD, SEM, FT-IR, and a series of electrochemical tests were used to analyze the prepared materials. Through the experiment, the LiNi0.5Mn1.5O4 material prepared at 800 °C has completely crystallized under the same time (12 h), with no impurity peaks, and with uniform particle size; the initial discharge capacity was 107.5 mAh·g−1 at 0.1 C. After the calcination temperature (800 °C) was determined, the material was sintered at 8, 12, 16, and 20 h. The material had sharp diffraction peaks, in complete crystal form, no LixNi1–xO impurity peak, and had good dispersion in the sample. At 5.0 C, the discharge capacity was 56.4 mAh·g−1.

Similar content being viewed by others

References

Gao ZG, Sun K, Cong LN et al (2016) High performance 5 V LiNi0.5Mn1.5O4 spinel cathode materials synthesized by an improved solid-state method[J]. J Alloys Compd 654:257–263

Li XT, Shao ZC, Zhang Y et al (2020) A Facile polymeric gel route synthesis of high-voltage LiNi0 5Mn1 5O4 cathode material for lithium-ion batteries[J]. Mater Lett 277:128310

Talebi EM, Savadogo O (2014) Enhancement of electrochemical properties of platinum doped LiFePO4/C cathode material synthesized using hydrothermal method[J]. Solid State Ionics 261:81–86

Mei Li (2012) Solvothermal synthesis of LiCo1−xMnxPO4/C cathode materials for lithium-ion batteries[J]. Ionics 18:507–512

Kumar KS, Choudhary N, Jung Y, Thomas J (2018) Recent advances in two-dimensional nanomaterials for supercapacitor electrode applications. ACS Energy Lett 3(2):482–495

Okada S, Sawa S, Egashira M et al (2001) Cathode properties of phospho-olivine LiMPO4 for lithium secondary batteries[J]. J Power Sources 97:430–432

Yano A, Shikano M, Ueda A et al (2017) LiCoO2 Degradation behavior in the high-voltage phase transition region and improved reversibility with surface coating[J]. J Electrochem Soc 164(1):6116–6122

Porthault H, Cras FL, Franger S (2012) Synthesis of LiCoO2 thin films by sol/gel process[J]. J Power Sources 195(19):6262–6267

Taha TA, Molla MM (2020) Green simple preparation of LiNiO2 nanopowder for lithium ion battery[J]. J Mater Res Technol 9(4):7955–7960

Markevich E, Salitra G, Hartmann P et al (2019) New insights related to rechargeable lithium batteries: Li metal anodes, Ni Rich LiNixCoyMnzO2 cathodes and beyond them[J]. J Electrochem Soc 166(3):A5265–A5274

Eddahech A, Briat O, Vinassa JM (2013) Lithium-ion battery performance improvement based on capacity recovery exploitation[J]. Electrochim Acta 114:750–757

Xiao ZL, Zhou Y, Song LB et al (2014) Thermal-electrochemical behaviors of LiMn2O4 lithium-ion cell studied by electrochemical–calorimetric method[J]. J Alloy Compd 592:226–230

Kim JH, Myung ST, Yoon CS et al (2004) Comparative study of LiNi0 5Mn1 5O4-δ and LiNi0 5Mn1 5O4 cathodes having two crystallographic structures: Fdm and P4332[J]. Chem Mater 16(5):906–914

Sung BP, Eom WS, Jang H et al (2006) Electrochemical properties of LiNi0.5Mn1.5O4 cathode after Cr doping[J]. J Power Sources 159:679–684

Aurbach D, Markovsky B, Talyossef Y et al (2006) Studies of cycling behavior, ageing, and interfacial reactions of LiNi0 5Mn1 5O4 and carbon electrodes for lithium-ion 5 V cells[J]. J Power Sources 162(2):780–789

Duncan H, Abu-Lebdeh Y, Davidson IJ (2010) Study of the cathode-electrolyte interface of LiNi0 5Mn1 5O4 synthesized by a sol-gel method for Li-ion batteries[J]. J Electrochem Soc 157(4):528–535

Arrebola JC, Caballero A, Hernan L et al (2008) A high energy Li-ion battery based on nanosized LiNi0 5Mn1 5O4 cathode material[J]. J Power Sources 183(1):310–315

Yi TF, Chen B, Zhu YR et al (2014) Enhanced rate performance of molybdenum-doped spinel LiNi0 5Mn1 5O4 cathode materials for lithium ion battery[J]. J Power Sources 247(2):778–785

Yi TF, Mei J, Zhu YR (2016) Key strategies for enhancing the cycling stability and rate capacity of LiNi0 5Mn1 5O4 as high-voltage cathode materials for high power lithium-ion batteries[J]. J Power Sources 316(1):85–105

Liu H, Lei T, Wang W et al (2018) Effects of raw materials on the electrochemical performance of Na-doped Li-rich cathode materials Li[Li0.2Ni0.2Mn0.6]O2[J]. Ionics 25:959–968

Zhong GB, Wang YY, Zhang ZC et al (2011) Effects of Al substitution for Ni and Mn on the electrochemical properties of LiNi0 5Mn1 5O4 [J]. Electrochimica Acta 56(18):6554–6561

Channu VSR, Rambabu B, Kumari K, Kalluru RR, Holze R (2016) High performance lithium insertion negative electrode materials forelectrochemical devices. Appl Surf Sci 387:839–845

Jiang Z, Gu H, Zhang J et al (2020) Study on the NiO-like phase in Ni-rich cathode materials for lithium ion batteries[J]. Ionics 18:4961–4967

Acknowledgements

The authors gratefully acknowledge supports by the Natural Science Foundation of Liaoning Province (No. 2020-BS-154).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zeng, F., Zhang, Y., Shao, Z. et al. The influence of different calcination temperatures and times on the chemical performance of LiNi0.5Mn1.5O4 cathode materials . Ionics 27, 3739–3748 (2021). https://doi.org/10.1007/s11581-021-04167-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-021-04167-x