Abstract

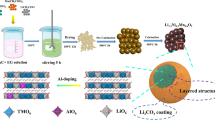

Aluminum-modified Li1.4Mn0.61Ni0.18Co0.18Al0.03O2.4 (LNCMA) and fluorine-modified LiNi0.5Mn1.5O3.9F0.1 (LNMOF) cathode materials were successfully synthesized via a solid-state reaction procedure. The discharge capacity of the LNCMA increased from 175.3 to 192.2 mAh g−1, showing approximately a 9.6% improvement after 50 cycles due to Al doping. For the LNMOF cathode, the discharge capacity increased from 116.9 to 174.9 mAh g−1 after F doping, corresponding to an increase of 49.6% after 50 cycles. The new composite cathode was formed by mixing the two cathode materials at a weight ratio of 1:1, which was selected based on the charge–discharge profiles during the first cycle. When the cells were tested in a voltage range of 2.0–4.85 V, the composite material exhibited initial specific capacities of 229.2 and 215.4 mAh g−1, a coulombic efficiency of 94.0% during the first cycle, and a capacity retention of 94.5% after 50 cycles at 0.2C. The concept of inserting irreversible Li ions from the Li-rich material into the 16c vacancy of the LNMOF was validated. The improved capacity was due to the plateau in the discharge capacity curves due to the Mn3+ → Mn2+ reduction. The charge–discharge capacities of the composite material were higher than those in the literature, as was the coulombic efficiency. The new composite material inherited a high-voltage plateau from the LNMOF and a high specific capacity from the LNCMA, and this material has great potential for future applications.

Similar content being viewed by others

References

Hu E, Wang X, Yu X, Yang X (2018) Probing the complexities of structural changes in layered oxide cathode materials for Li-ion batteries during fast charge-discharge cycling and heating. Acc Chem Res 51:290–298. https://doi.org/10.1021/acs.accounts.7b00506

Thackeray MM, Johnson CS, Vaughey JT, Li N, Hackney SA (2005) Advances in manganese-oxide ‘composite’ electrodes for lithium-ion batteries. J Mater Chem 15:2257–2267. https://doi.org/10.1039/B417616M

Nayak PK, Erickson EM, Schipper F, Penki TR, Munichandraiah N, Adelhelm P, Sclar H, Amalraj F, Markovsky B, Aurbach D (2018) Review on challenges and recent advances in the electrochemical performance of high capacity Li- and Mn-rich cathode materials for Li-ion batteries. Adv Energy Mater 8:1702397. https://doi.org/10.1002/aenm.201702397

Yu H, Kim H, Wang Y, He P, Asakura D, Nakamura Y, Zhou H (2012) High-energy ‘composite’ layered manganese-rich cathode materials via controlling Li2MnO3 phase activation for lithium-ion batteries. Phys Chem Chem Phys 14:6584–6595. https://doi.org/10.1039/C2CP40745K

West WC, Soler J, Smart MC, Ratnakumara BV, Firdosya S, Ravia V, Andersona MS, Hrbacekc J, Leec ES, Manthiramc A (2011) Electrochemical behavior of layered solid solution Li2MnO3·LiMO2 (M= Ni, Mn, Co) Li-ion cathodes with and without alumina coatings. J Electrochem Soc 158:A883–A889. https://doi.org/10.1149/1.3597319

Rana J, Kloepsch R, Li J, Scherb T, Schumacher G, Winter M, Banhart J (2014) On the structural integrity and electrochemical activity of a 0.5Li2MnO3·0.5LiCoO2 cathode material for lithium-ion batteries. J Mater Chem A 2:9099–9110. https://doi.org/10.1039/C4TA01161A

Croy JR, Kang SH, Balasubramanian M, Thackeray MM (2011) Li2MnO3-based composite cathodes for lithium batteries: a novel synthesis approach and new structures. Electrochem Commun 13:1063–1066. https://doi.org/10.1016/j.elecom.2011.06.037

Thackeray MM, Kang SH, Johnson CS, Vaughey JT, Benedek R, Hackney SA (2007) Li2MnO3-stabilized LiMO2 (M= Mn, Ni, Co) electrodes for lithium-ion batteries. J Mater Chem 17:3112–3125. https://doi.org/10.1039/B702425H

Rana J, Stan M, Kloepsch R, Li J, Schumacher G, Welter E, Zizak I, Banhart J, Winter M (2014) Structural changes in Li2MnO3 cathode material for Li-ion batteries. Adv Energy Mater 4:1300998. https://doi.org/10.1002/aenm.201300998

Thackeray MM (1997) Manganese oxides for lithium batteries. Prog Solid State Chem 25:1–71. https://doi.org/10.1016/S0079-6786(97)81003-5

Talyosef Y, Markovsky B, Lavi R, Salitraa G, Aurbacha D, Kovachevab D, Gorovab M, Zhechevab E, Stoyanovab R (2007) Comparing the behavior of nano-and microsized particles of LiMn1.5Ni0.5O4 spinel as cathode materials for Li-ion batteries. J Electrochem Soc 154:A682–A691. https://doi.org/10.1149/1.2736657

Xiao J, Chen X, Sushko PV, Sushko ML, Kovarik L, Feng J, Deng Z, Zheng J, Graff GL, Nie Z, Choi D, Liu J, Zhang JG, Whittingham MS (2012) High-performance LiMn1.5Ni0.5O4 spinel controlled by Mn3+ concentration and site disorder. Adv Mater 24:2109–2116. https://doi.org/10.1002/adma.201104767

Armstrong G, Armstrong AR, Bruce PG, Reale P, Scrosati B (2006) TiO2(B) nanowires as an improved anode material for lithium-ion batteries containing LiFePO4 or LiMn1.5Ni0.5O4 cathodes and a polymer electrolyte. Adv Mater 18:2597–2600. https://doi.org/10.1002/adma.200601232

Arrebola JC, Caballero A, Cruz M, Hernán L, Morales J, Castellón ER (2006) Crystallinity control of a nanostructured LiNi0.5Mn1.5O4 spinel via polymer-assisted synthesis: a method for improving its rate capability and performance in 5 V lithium batteries. Adv Funct Mater 16:1904–1912. https://doi.org/10.1002/adfm.200500892

Mokhtar N, Idris NH (2016) Comparison on electrochemical performances of LiNi0.5Mn1.5O4 cathode materials synthesized using different precursors. Mater Today Proc 3S:S129–S135. https://doi.org/10.1016/j.matpr.2016.01.017

Xiao Y, Fan J, Zhang X, Zhang D, Chang C (2019) Li2Ni0.5Mn1.5O4, spinel type cathode material with high reversible capacity. Electrochim Acta 311:170–177. https://doi.org/10.1016/j.electacta.2019.04.162

Thackeray MM, David WIF, Bruce PG, Goodenough JB (1983) Lithium insertion into manganese spinels. Mater Res Bull 18:461–472. https://doi.org/10.1016/0025-5408(83)90138-1

Park SH, Oh SW, Yoon CS, Myung ST, Sun YK (2005) LiNi0.5Mn1.5O4 showing reversible phase transition on 3 V region. Electrochem Solid-State Lett 8:A163–A167. https://doi.org/10.1149/1.1857113

Thackeray MM (1999) Spinel electrodes for lithium batteries. J Am Ceram Soc 82:3347–3354. https://doi.org/10.1111/j.1151-2916.1999.tb02250.x

Oh SH, Jeon SH, Cho WI, Kim CS, Cho BW (2008) Synthesis and characterization of the metal-doped high-voltage spinel LiNi0.5Mn1.5O4 by mechanochemical process. J Alloy Compd 452:389–396. https://doi.org/10.1016/j.jallcom.2006.10.153

Lee ES, Huq A, Chang HY, Manthiram A (2012) High-voltage, high-energy layered-spinel composite cathodes with superior cycle life for lithium-ion batteries. Chem Mater 24:600–612. https://doi.org/10.1021/cm2034992

Vidal E, Rojo JM, García-Alegre MC, Guinea D, Soto E, Amarilla JM (2013) Effect of composition, sonication and pressure on the rate capability of 5 V-LiNi0.5Mn1.5O4 composite cathodes. Electrochim Acta 108:175–181. https://doi.org/10.1016/j.electacta.2013.06.090

Cheng F, Liang J, Tao Z, Chen J (2011) Functional materials for rechargeable batteries. Adv Mater 23:1695–1715. https://doi.org/10.1002/adma.201003587

Kim D, Sandi G, Croy JR, Gallagher KG, Kang SH, Lee E, Slater MD, Johnson CS, Thackeray MM (2013) Composite ‘layered-layered-spinel’ cathode structures for lithium-ion batteries. J Electrochem Soc 160:A31–A38. https://doi.org/10.1149/2.049301jes

He W, Qian J, Cao Y, Ai X, Yang H (2012) Improved electrochemical performances of nanocrystalline Li[Li0.2Mn0.54Ni0.13Co0.13]O2 cathode material for Li-ion batteries. RSC Adv 2:3423–3429. https://doi.org/10.1039/C2RA20122D

Kim D, Shiiba H, Zettsu N, Yamada T, Kimijima T, Sánchez-Santolino G, Ishikawa R, Ikuhara Y, Teshima K (2017) Full picture discovery for mixed-fluorine anion effects on high-voltage spinel lithium nickel manganese oxide cathodes. NPG Asia Mater 9:e398. https://doi.org/10.1038/am.2017.90

Hagh NM, Amatucci GG (2014) Effect of cation and anion doping on microstructure and electrochemical properties of the LiMn1.5Ni0.5O4-δ spinel. J Power Sources 256:457–469. https://doi.org/10.1016/j.jpowsour.2013.12.135

Wen W, Ju B, Wang X, Wu C, Shu H, Yang X (2014) Effects of magnesium and fluorine co-doping on the structural and electrochemical performance of the spinel LiMn2O4 cathode materials. Electrochim Acta 147:271–278. https://doi.org/10.1016/j.electacta.2014.09.115

Park SH, Oh SW, Kang SH, Belharouak I, Amine K, Sun YK (2007) Comparative study of different crystallographic structure of LiNi0.5Mn1.5O4-δ cathodes with wide operation voltage (2.0-5.0V). Electrochim Acta 52:7226–7230. https://doi.org/10.1016/j.electacta.2007.05.050

Park SH, Kang SH, Johnson CS, Amine K, Thackeray MM (2007) Lithium-manganese-nickel-oxide electrodes with integrated layered-spinel structures for lithium batteries. Electrochem Commun 9:262–268. https://doi.org/10.1016/j.elecom.2006.09.014

Li J, Klöpsch R, Stan MC, Nowak S, Kunze M, Winter M, Passerini S (2011) Synthesis and electrochemical performance of the high voltage cathode material Li[Li0.2Mn0.56Ni0.16Co0.08]O2 with improved rate capability. J Power Sources 196:4821–4825. https://doi.org/10.1016/j.jpowsour.2011.01.006

Bhaskar A, Krueger S, Siozios V, Li J, Nowak S, Winter M (2014) Synthesis and characterization of high-energy, high-power spinel-layered composite cathode materials for Lithium-ion batteries. Adv Energy Mater 5:1401156. https://doi.org/10.1002/aenm.201401156

Martha SK, Nanda J, Veith GM, Dudney NJ (2012) Electrochemical and rate performance study of high-voltage lithium-rich composition: Li1.2Mn0.525Ni0.175Co0.1O2. J Power Sources 199:220–226. https://doi.org/10.1016/j.jpowsour.2011.10.019

Wang S, Chen H, Zhong Z, Hou X, Hu S, Wu J (2018) Graphene-decorated sphere Li2S composite prepared by spray drying method as cathode for lithium-sulfur full cell. Ionics 24:3385–3392. https://doi.org/10.1007/s11581-018-2493-7

Xie D, Zhou W, Lin K, Hu C, Zheng P, Hou X, Lam KH (2019) Doping effect of fluoride anion on microstructural and electrochemical properties of lithium-rich cathode materials. Mater Lett 253:82–85. https://doi.org/10.1016/j.matlet.2019.06.047

Zhou Y, Hou X, Shen K, Wang S, Chen F, Li Y, Chen H, Wang B (2019) Li1.1Na0.1Mn0.534 Ni0.133Co0.133O2 as cathode with ameliorated electrochemical performance based on dual Li+/Na+ electrolyte. Ionics 25:51–59. https://doi.org/10.1007/s11581-018-2587-2

Goodenough JB, Thackeray MM, David WF, Bruce PG (1984) Lithium insertion/extraction reactions with manganese oxides. Rev Chim Mineral 21:435–455

Hoang K (2014) Understanding the electronic and ionic conduction and lithium over-stoichiometry in LiMn2O4 spinel. J Mater Chem A 2:18271–18280. https://doi.org/10.1039/C4TA04116J

Acknowledgments

The authors are grateful to the support from the Science and Technology Commission of Shanghai Municipality (14520503100, 13PJ1407400, and 201310-JD-B2-009) and Shanghai Municipal Education Commission (15ZZ095). We thank LetPub (www.letpub.com) for its linguistic assistance during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, H., Xiao, Y., Dong, J. et al. New composite Li1.4Mn0.61Ni0.18Co0.18Al0.03O2.4 and LiNi0.5Mn1.5O3.9F0.1 cathode material with higher specific capacity and better capacity retention. Ionics 26, 3749–3760 (2020). https://doi.org/10.1007/s11581-020-03559-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-020-03559-9