Abstract

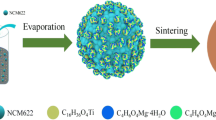

LiNi0.8Co0.15Al0.05O2 (NCA) has become one of the research focuses due to its advantages including low cost and high reversible capacity. However, many drawbacks such as the dissolution of the cation into the electrolyte caused by hydrofluoric acid severely limited its electrochemical performance. In this study, Co3O4 derived from metal-organic frameworks (MOFs) is coated on the surface of commercial NCA utilizing in situ growth followed by annealing. The structure and morphology of the samples are characterized by X-ray diffraction, scanning electron microscope, and transmission electron microscope. NCA@Co3O4 delivers a remarkable capacity retention of 73.7% and 84.4% at 1 C and 2 C after 100 cycles at each rate, respectively. Meanwhile, the rate performance of NCA@Co3O4 is significantly improved. The inhibition of the side reaction between cathode materials and electrolyte, and the reduced charge-transfer resistance that brought by Co3O4 coating layer are the main reasons for the excellent electrochemical performance.

Similar content being viewed by others

References

Zhao Y, Li X, Yan B, Li D, Lawes S, Sun X (2015) Significant impact of 2D graphene nanosheets on large volume change tin-based anodes in lithium-ion batteries: a review. J Power Sources 274:869–884. https://doi.org/10.1016/j.jpowsour.2014.10.008

Barré A, Deguilhem B, Grolleau S, Gérard M, Suard F, Riu D (2013) A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J Power Sources 241:680–689. https://doi.org/10.1016/j.jpowsour.2013.05.040

Kucinskis G, Bajars G, Kleperis J (2013) Graphene in lithium ion battery cathode materials: a review. J Power Sources 240:66–79. https://doi.org/10.1016/j.jpowsour.2013.03.160

Guo S, Yu H, Liu P, Liu X, Li D, Chen M, Ishida M, Zhou H (2014) Surface coating of lithium–manganese-rich layered oxides with delaminated MnO2 nanosheets as cathode materials for Li-ion batteries. J Mater Chem A 2:4422–4428. https://doi.org/10.1039/c3ta15206e

Qiu H, Yue H, Zhang T, Li T, Wang C, Chen G, Wei Y, Zhang D (2016) Enhanced electrochemical performance of Li2FeSiO4/C cathode materials by surface modification with AlPO4 nanosheets. Electrochim Acta 222:1870–1877. https://doi.org/10.1016/j.electacta.2016.11.180

Xu X, Deng S, Wang H, Liu J, Yan H (2017) Research Progress in improving the cycling stability of high-voltage LiNi0.5Mn1.5O4 cathode in lithium-ion battery. Nano-Micro Lett 9:22. https://doi.org/10.1007/s40820-016-0123-3

An S, Li J, Daniel C, Mohanty D, Nagpure S, Wood D III (2016) The state of understanding of the lithium-ion-battery graphite solid electrolyte interphase (SEI) and its relationship to formation cycling. Carbon 105:52–76. https://doi.org/10.1016/j.carbon.2016.04.008

Liang M, Song D, Zhang H, Shi X, Wang Q, Zhang L (2017) Improved performances of LiNi0.8Co0.15Al0.05O2 material employing NaAlO2 as a new aluminum source. ACS Appl Mater Interfaces 9:38567–38574. https://doi.org/10.1021/acsami.7b12306

Kasnatscheew J, Evertz M, Streipert B, Wagner R, Nowak S, Cekic Laskovic I, Winter M (2017) Changing established belief on capacity fade mechanisms: thorough investigation of LiNi1/3Co1/3Mn1/3O2 (NCM111) under high voltage conditions. J Phys Chem C 121:1521–1529. https://doi.org/10.1021/acs.jpcc.6b11746

Liu X, Liu J, Huang T, Yu A (2013) CaF2-coated Li1.2Mn0.54Ni0.13Co0.13O2 as cathode materials for Li-ion batteries. Electrochim Acta 109:52–58. https://doi.org/10.1016/j.electacta.2013.07.069

Lai Y, Xu M, Zhang Z, Gao C, Wang P, Yu Z (2016) Optimized structure stability and electrochemical performance of LiNi0.8Co0.15Al0.05O2 by sputtering nanoscale ZnO film. J Power Sources 309:20–26. https://doi.org/10.1016/j.jpowsour.2016.01.079

Ding J, Lu Z, Wu M, Liu C, Ji H, Yang G (2017) Preparation and performance characterization of AlF3 as interface stabilizer coated Li1.24Ni0.12Co0.12Mn0.56O2 cathode for lithium-ion batteries. Appl Surf Sci 406:21–29. https://doi.org/10.1016/j.apsusc.2017.02.115

Wang Y, Qiu J, Yu Z, Ming H, Li M, Zhang S, Yang Y (2018) AlF3-modified LiCoPO4 for an advanced cathode towards high energy lithium-ion battery. Ceram Int 44:1312–1320. https://doi.org/10.1016/j.ceramint.2017.08.084

Yi T, Li Y, Li X, Pan J, Zhang Q, Zhu Y (2017) Enhanced electrochemical property of FePO4-coated LiNi0.5Mn1.5O4 as cathode materials for Li-ion battery. Sci Bull 62:1004–1010. https://doi.org/10.1016/j.scib.2017.07.003

Li X, Xie Z, Liu W, Ge W, Wang H, Qu M (2015) Effects of fluorine doping on structure, surface chemistry, and electrochemical performance of LiNi0.8Co0.15Al0.05O2. Electrochim Acta 174:1122–1130. https://doi.org/10.1016/j.electacta.2015.06.099

Xie H, Du K, Hu G, Peng Z, Cao Y (2016) The role of sodium in LiNi0.8Co0.15Al0.05O2 cathode material and its electrochemical behaviors. J Phys Chem C 120:3235–3241. https://doi.org/10.1021/acs.jpcc.5b12407

Hou P, Zhang H, Deng X, Xu X, Zhang L (2017) Stabilizing the electrode/electrolyte interface of LiNi0.8Co0.15Al0.05O2 through tailoring aluminum distribution in microspheres as long-life, high-rate, and safe cathode for lithium-ion batteries. ACS Appl Mater Interfaces 9:29643–29653. https://doi.org/10.1021/acsami.7b05986

Huang B, Li X, Wang Z, Guo H, Shen L, Wang J (2014) A comprehensive study on electrochemical performance of Mn-surface-modified LiNi0.8Co0.15Al0.05O2 synthesized by an in situ oxidizing-coating method. J Power Sources 252:200–207. https://doi.org/10.1016/j.jpowsour.2013.11.092

Zhao J, Wang Z, Wang J, Guo H, Li X, Gui W, Chen N, Yan G (2018) Anchoring K+ in Li+ sites of LiNi0.8Co0.15Al0.05O2 cathode material to suppress its structural degradation during high-voltage cycling. Energy Technol. https://doi.org/10.1002/ente.201800361

Xu X, Qi C, Hao Z, Wang H, Jiu J, Liu J, Yan H, Suganuma K (2018) The surface coating of commercial LiFePO4 by utilizing ZIF-8 for high electrochemical performance lithium ion battery. Nano-Micro Lett 10:1. https://doi.org/10.1007/s40820-017-0154-4

Shi S, Tu J, Tang Y, Liu X, Zhang Y, Wang X, Gu C (2013) Enhanced cycling stability of Li[Li0.2Mn0.54Ni0.13Co0.13]O2 by surface modification of MgO with melting impregnation method. Electrochim Acta 88:671–679. https://doi.org/10.1016/j.electacta.2012.10.111

Xiang J, Chang C, Yuan L, Sun J (2008) A simple and effective strategy to synthesize Al2O3-coated LiNi0.8Co0.2O2 cathode materials for lithium ion battery. Electrochem Commun 10:1360–1363. https://doi.org/10.1016/j.elecom.2008.07.012

Kim J, Kim D, Oh D, Lee H, Kim J, Lee J, Jung Y (2015) Surface chemistry of LiNi0.5Mn1.5O4 particles coated by Al2O3 using atomic layer deposition for lithium-ion batteries. J Power Sources 274:1254–1262. https://doi.org/10.1016/j.jpowsour.2014.10.207

Han E, Li Y, Zhu L, Zhao L (2014) The effect of MgO coating on Li1.17Mn0.48Ni0.23Co0.12O2 cathode material for lithium ion batteries. Solid State Ionics 255:113–119. https://doi.org/10.1016/j.ssi.2013.12.018

Qiu B, Wang J, Xia Y, Wei Z, Han S, Liu Z (2014) Enhanced electrochemical performance with surface coating by reactive magnetron sputtering on lithium-rich layered oxide electrodes. ACS Appl Mater Interfaces 6:9185–9193. https://doi.org/10.1021/am501293y

Xu X, Wang H, Liu J, Yan H (2017) The applications of zeolitic imidazolate framework-8 in electrical energy storage devices: a review. J Mater Sci - Mater Electron 28:7532–7543. https://doi.org/10.1007/s10854-017-6485-6

Han Y, Zhao M, Dong L, Feng J, Wang Y, Li D, Li X (2015) MOF-derived porous hollow Co3O4 parallelepipeds for building high-performance Li-ion batteries. J Mater Chem A 3:22542–22546. https://doi.org/10.1039/c5ta06205e

Zhang C, Xiao J, Lv X, Qian L, Yuan S, Wang S, Lei P (2016) Hierarchically porous Co3O4/C nanowire arrays derived from a metal–organic framework for high performance supercapacitors and the oxygen evolution reaction. J Mater Chem A 4:16516–16523. https://doi.org/10.1039/c6ta06314d

Pu J, Wan J, Wang Y, Ma Y (2016) Different Co-based MOFs templated synthesis of Co3O4 nanoparticles to degrade RhB by activation of oxone. RSC Adv 6:91791–91797. https://doi.org/10.1039/c6ra15590a

Wu R, Wang D, Rui X, Liu B, Zhou K, Law A, Yan Q, Wei J, Chen Z (2015) In-situ formation of hollow hybrids composed of cobalt sulfides embedded within porous carbon polyhedra/carbon nanotubes for high-performance lithium-ion batteries. Adv Mater 27:3038–3044. https://doi.org/10.1002/adma.201500783

Wu R, Qian X, Rui X, Liu H, Yadian B, Zhou K, Wei J, Yan Q, Feng X, Long Y, Wang L, Huang Y (2014) Zeolitic imidazolate framework 67-derived high symmetric porous Co3O4 hollow dodecahedra with highly enhanced lithium storage capability. Small 10:1932–1938. https://doi.org/10.1002/smll.201303520

Jiang Z, Lu W, Li Z, Ho KH, Li X, Jiao X, Chen D (2014) Synthesis of amorphous cobalt sulfide polyhedral nanocages for high performance supercapacitors. J Mater Chem A 2:8603–8606. https://doi.org/10.1039/c3ta14430e

Qian J, Sun F, Qin L (2012) Hydrothermal synthesis of zeolitic imidazolate framework-67 (ZIF-67) nanocrystals. Mater Lett 82:220–223. https://doi.org/10.1016/j.matlet.2012.05.077

Zhang E, Xie Y, Ci S, Jia J, Wen Z (2016) Porous Co3O4 hollow nanododecahedra for nonenzymatic glucose biosensor and biofuel cell. Biosens Bioelectron 81:46–53. https://doi.org/10.1016/j.bios.2016.02.027

Lin K, Chang H (2015) Ultra-high adsorption capacity of zeolitic imidazole framework-67 (ZIF-67) for removal of malachite green from water. Chemosphere 139:624–631. https://doi.org/10.1016/j.chemosphere.2015.01.041

Yoon W, Chung K, McBreen J, Yang X (2006) A comparative study on structural changes of LiCo1/3Ni1/3Mn1/3O2 and LiNi0.8Co0.15Al0.05O2 during first charge using in situ XRD. Electrochem Commun 8:1257–1262. https://doi.org/10.1016/j.elecom.2006.06.005

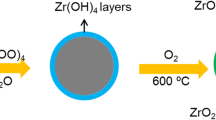

Wu N, Wu H, Liu H, Zhang Y (2016) Solvothermal coating LiNi0.8Co0.15Al0.05O2 microspheres with nanoscale Li2TiO3 shell for long lifespan Li-ion battery cathode materials. J Alloys Compd 665:48–56. https://doi.org/10.1016/j.jallcom.2016.01.044

Lebedev O, Millange F, Serre C, Tendeloo G, Férey G (2005) First direct imaging of giant pores of the metal−organic framework MIL-101. Chem Mater 17:6525–6527. https://doi.org/10.1021/cm051870o

Zhang D, Zhu Y, Liu L, Ying X, Hsiung C, Sougrat R, Li K, Han Y (2018) Atomic-resolution transmission electron microscopy of electron beam–sensitive crystalline materials. Science 359:675–679. https://doi.org/10.1126/science.aao0865

Cravillon J, Münzer S, Lohmeier S, Feldhoff A, Huber K, Wiebcke M (2009) Rapid room-temperature synthesis and characterization of nanocrystals of a prototypical zeolitic imidazolate framework. Chem Mater 21:1410–1412. https://doi.org/10.1021/cm900166h

Zhu L, Zhang D, Xue M, Li H, Qiu S (2013) Direct observations of the MOF (UiO-66) structure by transmission electron microscopy. CrystEngComm 15:9356–9359. https://doi.org/10.1039/c3ce41122b

Wiktor C, Turner S, Zacher D, Fischer R, Tendeloo G (2012) Imaging of intact MOF-5 nanocrystals by advanced TEM at liquid nitrogen temperature. Microporous Mesoporous Mater 162:131–135. https://doi.org/10.1016/j.micromeso.2012.06.014

Huang Y, Huang Y, Hu X (2017) Enhanced electrochemical performance of LiNi0.8Co0.15Al0.05O2 by nanoscale surface modification with Co3O4. Electrochim Acta 231:294–299. https://doi.org/10.1016/j.electacta.2017.02.067

Yan X, Chen L, Shah S, Liang J, Liu Z (2017) The effect of Co3O4 & LiCoO2 cladding layer on the high rate and storage property of high nickel material LiNi0.8Co0.15Al0.05O2 by simple one-step wet coating method. Electrochim Acta 249:179–188. https://doi.org/10.1016/j.electacta.2017.07.015

Wu F, Wang M, Su Y, Chen S (2009) Surface modification of LiCo1/3Ni1/3Mn1/3O2 with Y2O3 for lithium-ion battery. J Power Sources 189:743–747. https://doi.org/10.1016/j.jpowsour.2008.08.014

Li L, Wang L, Zhang X, Xie M, Wu F, Chen R (2015) Structural and electrochemical study of hierarchical LiNi1/3Co1/3Mn1/3O2 cathode material for lithium-ion batteries. ACS Appl Mater Interfaces 7:21939–21947. https://doi.org/10.1021/acsami.5b06584

Zhu L, Liu Y, Wu W, Wu X, Tang W, Wu Y (2015) Surface fluorinated LiNi0.8Co0.15Al0.05O2 as a positive electrode material for lithium ion batteries. J Mater Chem A 3:15156–15162. https://doi.org/10.1039/c5ta02529j

Li J, Xiong S, Liu Y, Ju Z, Qian Y (2013) Uniform LiNi1/3Co1/3Mn1/3O2 hollow microspheres: designed synthesis, topotactical structural transformation and their enhanced electrochemical performance. Nano Energy 2:1249–1260. https://doi.org/10.1016/j.nanoen.2013.06.003

Pan W, Peng W, Yan G, Guo H, Wang Z, Li X, Gui W, Wang J, Chen N (2018) Suppressing the voltage decay and enhancing the electrochemical performance of Li1.2Mn0.54Co0.13Ni0.13O2 by multifunctional Nb2O5 coating. Energy Technol. https://doi.org/10.1002/ente.201800253

Funding

This work is supported by the Scientific and Technological Development Project of the Beijing Education Committee (No. KZ201710005009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hao, Z., Xu, X., Deng, S. et al. In situ growth of Co3O4 coating layer derived from MOFs on LiNi0.8Co0.15Al0.05O2 cathode materials. Ionics 25, 2469–2476 (2019). https://doi.org/10.1007/s11581-018-2726-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-018-2726-9