Abstract

To accelerate the development of strategies for cartilage tissue engineering, models are necessary to investigate the interactions between cellular dynamics and the local microenvironment. We use a discrete framework to capture the individual behavior of cells, modeling experiments where cells are seeded in a porous scaffold or hydrogel and over the time course of a month, the scaffold slowly degrades while cells divide and synthesize extracellular matrix constituents. The movement of cells and the ability to proliferate is a function of the local porosity, defined as the volume fraction of fluid in the surrounding region. A phenomenological approach is used to capture a continuous profile for the degrading scaffold and accumulating matrix, which will then change the local porosity throughout the construct. We parameterize the model by first matching total cell counts in the construct to chondrocytes seeded in a polyglycolic acid scaffold (Freed et al. in Biotechnol Bioeng 43:597–604, 1994). We investigate the influence of initial scaffold porosity on the total cell count and spatial profiles of cell and ECM in the construct. Cell counts were higher at day 30 in scaffolds of lower initial porosity, and similar cell counts were obtained using different models of scaffold degradation and matrix accumulation (either uniform or cell-specific). Using this modeling framework, we study the interplay between a phenomenological representation of scaffold architecture and porosity as well as the potential continuous application of growth factors. We determine parameter regimes where large cellular aggregates occur, which can hinder matrix accumulation and cellular proliferation. The developed modeling framework can easily be extended and can be used to identify optimal scaffolds and culture conditions that lead to a desired distribution of extracellular matrix and cell counts throughout the construct.

Similar content being viewed by others

References

Alden K, Read M, Timmis J, Andrews PS, Veiga-Fernandes H, Coles M (2013) Spartan: a comprehensive tool for understanding uncertainty in simulations of biological systems. PLoS Comput Biol 9:e1002916

Akalp U, Bryant SJ, Vernerey FJ (2016) Tuning tissue growth with scaffold degradation in enzyme-sensitive hydrogels: a mathematical model. Soft Matter 12:7505–7520

Archer CW, Francis-West P (2003) The chondrocyte. Int J Biochem Cell Biol 35:401–404

Akkiraju H, Nohe A (2015) Role of chondrocytes in cartilage formation, progression of osteoarthritis and cartilage regeneration. J Dev Biol 3:177–192

Al-Husari M, Murdoch C, Webb SD (2014) A cellular automaton model examining the effects of oxygen, hydrogen ions and lactate on early tumour growth. J Math Biol 69:839–873

Bandeiras C, Completo A, Ramos A (2015) Influence of the scaffold geometry on the spatial and temporal evolution of the mechanical properties of tissue-engineered cartilage: insights from a mathematical model. Biomech Model Mechanobiol 14:1057–1070

Bian L, Hou C, Tous E, Rai R, Mauck RL, Burdick JA (2013) The influence of hyaluronic acid hydrogel crosslinking density and macromolecular diffusivity on human MSC chondrogenesis and hypertrophy. Biomaterials 34:413–421

Buxton AN, Zhu J, Marchant R, West JL, Yoo JU, Johnston B (2007) Design and characterization of poly(ethylene glycol) photopolymerizable semi-interpenetrating networks for chondrogenesis of human mesenchymal stem cells. Tissue Eng 13:2549–2560

Byrne H, Drasdo D (2009) Individual-based and continuum models of growing cell populations: a comparison. J Math Biol 58:657–687

Cheng G, Youssef BB, Markenscoff P, Zygourakis K (2006) Cell population dynamics modulate the rates of tissue growth processes. Biophys J 90:713–724

Cheng G, Markenscoff P, Zygourakis K (2009) A 3D hybrid model for tissue growth: the interplay between cell population and mass transport dynamics. Biophys J 97:401–414

Choi JR, Yong KW, Choi JY (2018) Effects of mechanical loading on human mesenchymal stem cells for cartilage tissue engineering. J Cell Physiol 233:1913–1928

Chung CA, Chen CW, Chen CP (2006) Analysis of cell growth and diffusion in a scaffold for cartilage tissue engineering. Biotech Bioeng 94(6):1138–1146

Chung CA, Chen CW, Chen CP, Tseng CS (2007) Enhancement of cell growth in tissue-engineering constructs under direct perfusion: modeling and simulation. Biotechnol Bioeng 97:1603–1616

Chung CA, Lin TH, Chen SD, Huang HI (2010) Hybrid cellular automaton modeling of nutrient modulated cell growth in tissue engineering constructs. J Theor Biol 262:267–278

Cigan AD, Roach BL, Nims RJ, Tan AR, Albro MB, Stoker AM, Cook JL, Vunjak-Novakovic G, Hung CT, Ateshian GA (2016) High seeding density of human chondrocytes in agarose produces tissue-engineered cartilage approaching native mechanical and biochemical properties. J Biomech 49:1909–1917

Cosgrove J, Butler J, Alden K, Read M, Kumar V, Cucurull-Sanchez L, Timmis J, Coles M (2015) Agent-based modeling in systems pharmacology. CPT Pharmacomet Syst Pharmacol 4:615–629

Dimicco MA, Sah RL (2003) Dependence of cartilage matrix composition on biosynthesis, diffusion and reaction. Transp Porous Media 50:57–73

Erickson E, Huang AH, Sengupta S, Kestle S, Burdick JA, Mauck RL (2009) Macromer density influences mesenchymal stem cell chondrogenesis and maturation in photocrosslinked hyaluronic acid hydrogels. Osteoarthr Cartilage 17:1639–1648

Fernandes H, Moroni L, van Bitterswijk C, de Boer J (2009) Extracellular matrix and tissue engineering applications. J Mater Chem 19:5474–5484

Freed LE, Vunjak-Novakovic G, Marquis JC, Langer R (1994) Kinetics of chondrocyte growth in cell-polymer implants. Biotechnol Bioeng 43:597–604

Freyria AM, Cortial D, Ronziere MC, Guerret S, Herbage D (2004) Influence of medium composition, static and stirred conditions on the proliferation of and matrix protein expression of bovine articular chondrocytes cultured in a 3-D collagen scaffold. Biomaterials 25:687–697

Freyria AM, Mallein-Gerin F (2012) Chondrocytes or adult stem cells for cartilage repair: the indisputable role of growth factors. Injury 43:259–265

Furukawa KS, Suenaga H, Toita K, Numata A, Tanaka J, Ushida T, Sakai Y, Tateishi T (2003) Rapid and large-scale formation of chondrocyte aggregates by rotational culture. Cell Transplant 12:475–479

Galle J, Hoffmann M, Aust G (2007) From single cells to tissue architecture-a bottom-up approach to modeling the spatio-temporal organisation of complex multi-cellular systems. J Math Biol 58:261–283

Goldring MB, Goldring SR (2007) Osteoarthritis. J Cell Phys 213:626–634

Haider MA, Olander JE, Arnold RF, Marous DR, McLamb AJ, Thompson KC, Woodruff WR, Haugh JM (2011) A phenomenological mixture model for biosynthesis and linking of cartilage extracellular matrix in scaffolds seeded with chondrocytes. Biomech Model Mechanobiol 10:915–924

Hamilton DW, Riehle MO, Monaghan W, Curtis AS (2006) Chondrocyte aggregation on micrometric surface topography: a time- lapse study. Tissue Eng 12:189–199

Hauselmann HJ, Aydelotte MB, Schumacher BL, Kuettner KE, Gitelis SH, Thonar E (1992) Synthesis and turnover of proteoglycans by human and bovine adult articular chondrocytes cultured in alginate beads. Matrix 12:116–129

Hossain MS, Bergstrom DJ, Chen XB (2015) Modelling and simulation of the chondrocyte cell growth, glucose consumption and lactate production within a porous tissue scaffold inside a perfusion bioreactor. Biotechnol Rep 5:55–62

Humphrey JD, Dufresne ER, Schwartz MA (2014) Mechanotransduction and extracellular matrix homeostasis. Nat Rev Mol Cell Biol 15:802–812

Jeon J, Quaranta V, Cummings PT (2010) An off-lattice hybrid discrete-continuum model of tumor growth and invasion. Biophys J 98:37–47

Kachi ND, Otaka A, Sim S, Kuwana Y, Tamada Y, Sunaga J, Adachi T, Tomita N (2010) Observation of chondrocyte aggregate formation and internal structure on micropatterned fibroin-coated surface. Bio-Med Mater Eng 20:55–63

Keeney M, Lai JH, Yang F (2011) Recent progress in cartilage tissue engineering. Curr Opin Biotechnol 22:734–740

Kino-oka M, Maeda Y, Ota Y, Yashiki S, Sugawara K, Yamamoto T, Taya M (2005) Process design of chondrocyte cultures with monolayer growth for cell expansion and subsequent three-dimensional growth for production of cultured cartilage. J Biosci Bioeng 1:67–76

Kino-oka M, Kagita S, Nadzir MM, Inoue H, Sugawara K, Taya M (2005) Direct measurement of oxygen concentration inside cultured cartilage for relating to spatial growth of rabbit chondrocytes. J Biosci Bioeng 110:363–366

Klangjorhor J, Phitak T, Pruksakorn D, Pothacharoen P, Kongtawelert P (2014) Comparison of growth factor absorbed scaffold and conventional scaffold with growth factor supplemented media for primary human articular chondrocyte 3D culture. BMC Biotechnol 14:108

Kock L, van Donkelaar CC, Ito K (2012) Tissue engineering of functional articular cartilage: the current status. Cell Tissue Res 347:613–627

Kolettas E, Buluwela L, Bayliss MT, Muir HI (1995) Expression of cartilage-specific molecules is retained on long-term culture of human articular chondrocytes. J Cell Sci 108:1991–1999

Krause AL, Beliaev D, Van Gorder RA, Waters SL (2018) Lattice and continuum modelling of a bioactive porous tissue scaffold. Math Med Biol. https://doi.org/10.1093/imammb/dqnxxx

Kretlow JD, Mikos AG (2008) From material to tissue: biomaterial development, scaffold fabrication, and tissue engineering. AIChE J 54:3048–3067

Lee K, Silva EA, Mooney DJ (2011) Growth factor delivery-based tissue engineering: general approaches and a review of recent developments. J R Soc Interface 8:153–170

Lemon G, King JR, Byrne HM, Jensen OE, Shakesheff KM (2006) Mathematical modeling of engineered tissue growth using a multiphase porous flow mixture theory. J Math Biol 52:571–594

Loh QL, Choong C (2013) Three-dimensional scaffolds for tissue engineering applications: role of porosity and pore size. Tissue Eng B 19:485–502

Madry H, Rey-Rico A, Venkatesan JK, Johnstone B, Cucchiarini M (2014) Transforming growth factor beta-releasing scaffolds for cartilage tissue engineering. Tissue Eng B 20:106–125

Mak AF (1986) The apparent viscoelastic behavior of articular cartilage: the contributions from the intrinsic matrix viscoelasticity and interstitial fluid flows. J Biomech Eng 108:123–130

Martin JR, Gupta MK, Page JM, Yu F, Davidson JM, Guelcher SA, Duvall CL (2014) A porous tissue engineering scaffold selectively degraded by cell-generated reactive oxygen species. Biomaterials 35:3766–3776

Masaro L, Zhu XX (1999) Physical models of diffusion for polymer solutions. Prog Polym Sci 24:731–775

Matsiko A, Gleeson JP, O’Brien FJ (2015) Scaffold mean pore size influences mesenchymal stem cell chondrogenic differentiation and matrix deposition. Tissue Eng A 21:486–497

Mohan R, Mohan N, Vaiikath D (2018) Hyaluronic acid dictates chondrocyte morphology and migration in composite gels. Tissue Eng A 24:1481–1491

Mollenhauer JA (2008) Perspectives on articular cartilage biology and osteoarthritis. Int J Care Injured 39:S5–S12

Morales TI (2007) Chondrocyte moves: clever strategies? Osteoarthr Cartil 15(8):861–871

Mow VC, Ratcliffe A, Poole AR (1992) Cartilage and diarthrodial joints as paradigms for hierarchical materials and structures. Biomaterials 13:67–97

Muir H (1995) The chondrocyte, architect of cartilage: biomechanics, structure, function and molecular biology of cartilage matrix macromolecules. BioEssays 17:1039–1048

Nava MM, Raimondi MT, Pietrabissa R (2013) A multiphysics 3D model of tissue growth under interstitial perfusion in a tissue engineering bioreactor. Biomech Model Mechanobiol 12:1169–79

Nicodemus GD, Skaallure SC, Bryant SJ (2011) Gel structure impacts pericellular and extracellular matrix deposition which subsequently alters metabolic activities in chondrocyte-laden PEG hydrogels. Acta Biomater 7:492–504

Nikolaev NI, Obradovic B, Versteeg HK et al (2010) A validated model of GAG deposition, cell distribution, and growth of tissue engineered cartilage cultured in a rotating bioreactor. Biotechnol Bioeng 105:842–853

Obradovic B, Meldon JH, Freed LE (2000) Glycosaminoglycan (GAG) deposition in engineered cartilage: experiments and mathematical model. AIChE J 46:1860–1871

O’Dea RD, Osborne JM, El Haj AJ, Byrne HM, Waters L (2013) The interplay between tissue growth and scaffold degradation in engineered tissue constructs. J Math Biol 67:1199–1225

Olson SD, Haider MA (2019) A computational reaction-diffusion model for biosynthesis and linking of cartilage extracellular matrix in cell-seeded scaffolds with varying porosity. Biomech Model Mechanobiol. https://doi.org/10.1007/s10237-018-01110-4

Podrazky V, Sedmerova V (1966) Densities of collagen dehydrated by some organic solvents. Cell Mol Life Sci 32:871–879

Pohlmeyer JV, Waters SL, Cummings LJ (2013) Mathematical model of growth factor driven haptotaxis and proliferation in a tissue engineering scaffold. Bull Math Biol 75(3):393–427

Read M, Andrews PS, Timmis J, Kumar V (2012) Techniques for grounding agent-based simulations in the real domain: a case study in experimental autoimmune encephalomyelitis. Math Comput Model Dyn 18:67–86

Reddi AH, Becerra J, Andrades JA (2011) Nanomaterials and hydrogel scaffolds for articular cartilage regeneration. Tissue Eng B 17:301–305

Sacco R, Causin P, Zunino P, Raimondi MT (2011) A multiphysics/multiscale 2D numerical simulation of scaffold-based cartilage regeneration under interstitial perfusion in a bioreactor. Biomech Model Mechanobiol 10:577–589

Sanchez-Adams J, Athanasiou KA (2010) Biomechanical characterization of single chondrocytes. In: Gefen A (ed) Cellular and biomeolecular mechanisms and mechanobiology: studies in mechanobiology, tissue enginering, and biomaterials, vol 4. Springer, Berlin

Sanaei P, Cummings LJ, Waters SL, Griffiths IM (2018) Curvature- and fluid-stress-driven tissue growth in a tissue-engineering scaffold pore. Biomech Model Mechanobiol. https://doi.org/10.1007/s10237-018-1103-y

Sengers BG, van Donkelaar CC, Oomens CWJ, Baaijens FPT (2004) The local matrix distribution and the functional development of tissue engineered cartilage, a finite element study. Ann Biomed Eng 32:1718–1727

Sengers BG, van Donkelaar CC, Oomens CWJ, Baaijens FPT (2005a) Computational study of culture conditions and nutrient supply in cartilage tissue engineering. Biotechnol Prog 21:1252–1261

Sengers BG, Heywood HK, Lee DA, Oomens CWJ, Bader DL (2005b) Nutrient utilization by bovine articular chondrocytes: a combined experimental and theoretical approach. J Biomech Eng 127:758–766

Sengers BG, Taylor M, Please CP, Oreffo OC (2007) Computational modelling of cell spreading and tissue regeneration in porous scaffolds. Biomaterials 28:1926–1940

Shakeel M, Matthews PC, Graham RS, Waters SL (2013) A continuum model of cell proliferation and nutrient transport in a perfusion bioreactor. Math Med Biol 30:21–44

Skaalure SC, Chu S, Bryant SJ (2015) An enzyme-sensitive PEG hydrogel based on aggrecan catabolism for cartilage tissue engineering. Adv Healthc Mater 4:420–431

Skaalure SC, Akalp U, Vernerey FJ, Bryant SJ (2016) Tuning reaction and diffusion degradation of enzyme-sensitive hydrogels. Adv Healthc Mater 5:432–438

Sridhar LS, Schneider MC, Chu S, de Roucy G, Bryant SJ, Vernerey FJ (2017) Heterogeneity is key to hydrogel-based cartilage tissue regeneration. Soft Matter 13(28):4841–4855

Sridharan B, Lin SM, Hwu AT, Laflin AD, Detamore MS (2015) Stem cells in aggregate form to enhance chondrogenesis in hydrogels. PLoS ONE 10:e0141479

Trewenack AJ, Please CP, Landman KA (2009) A continuum model for the development of tissue-engineered cartilage around a chondrocyte. Math Med Biol 26:241–262

Vargha A, Delaney HD (2000) A critique and improvement of the CL common language effect size statistics of McGraw and Wong. J Educ Behav Stat 25:101–132

Vunjak-Novakic G, Obradovic B, Martin I, Bursac PM, Langer R, Freed LE (1998) Dynamic cell seeding of polymer scaffolds for cartilage tissue engineering. Biotechnol Prog 14:193–202

Wilson CG, Bonassar LJ, Kohles SS (2002) Modeling the dynamic composition of engineered cartilage. Arch Biochem Biophys 408:246–254

Wolf F, Candrian C, Wendt D, Farhadi J, Heberer M, Martin I, Barbero A (2008) Cartilage tissue engineering using pre-aggregated human articular chondrocytes. Euro Cells Mater 16:92–99

Wong M, Carter DR (2003) Articular cartilage functional histomorphology and mechanobiolgy: a research perspective. Bone 33:1–13

Zhang L, Whang Z, Sagotsky JA, Deisboeck TS (2009) Multiscale agent-based cancer modeling. J Math Biol 58:545–559

Zhang H, Zhou L, Zhang W (2014) Control of scaffold degradation in tissue engineering: a review. Tissue Eng B 20:492–502

Acknowledgements

We would like to acknowledge Mansoor Haider for useful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix

Details on Simulation Algorithm

1.1 Cell Discretization, Initialization and Boundary Conditions

Cells are discrete entities described as circles with constant diameter \(c_d\) with a surface covering 48 grid points spread around the cell center. At time zero, cells are randomly positioned on the domain \(\varOmega \) to avoid overlap, and cells are initialized with a random age in the interval [0, 3] days. Note that we use the same cell initialization for all simulations and that cell locations are independent of the computational grid for the continuous variables.

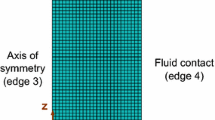

In Fig. 1b, the computational domain \(\varOmega \) is highlighted in dark gray. Since cells tend to stay within the bio-construct, we assume a no-flux boundary condition on all edges of the domain. If the chosen direction would place a cell outside of the domain, the trajectory is corrected before the cell moves to keep the cell inside the domain. The correction is performed on the coordinate that would exceed the computational domain by reversing the chosen movement direction and reducing its magnitude by a factor of ten. The boundary of the computational domain is padded with several layers of ghost grid points initialized with a value of \(p=0\) for porosity. Therefore, when a cell is close to the boundary, if part of the region depicted in Fig. 12 covers any ghost node, that specific direction will be automatically penalized by the direction rules, (7) and (8), to minimize the chances that a cell will exit the domain or will divide outside the domain.

1.2 Moving Cells

For each cell that is in the moving state, i.e., \(S_i^{j+1}={\mathcal {M}}\), the angle \(\theta _m\) in Eq. (1) needs to be chosen to update the new cell center location. As shown in Fig. 12, the cell will move in nine possible directions denoted by: \(\mathbf {\varnothing }\), E, NE, N, NW, W, SW, S, SE. The first direction corresponds to the small probability of staying in the same exact position if the cell is in the moving state whereas the other directions correspond to the cardinal and intercardinal directions.

Schematic of a cell (shaded gray circle in center) on the computational domain where the eight cardinal and intercardinal directions (E, NE, N, NW, W, SW, S, SE) are shown. The circle on each grid box corresponds to the node value tracking the average porosity and nutrient concentration on that particular volume element. The porosity values are assessed in the direction of no movement \(\mathbf {\varnothing }\), on the nodes included in the shaded gray area, and in the eight cardinal and intercardinal directions, on the nodes contained in the annulus surrounding the cell. The inner diameter of the annulus corresponds to \(c_d\) while the outer diameter of the annulus \(a_{d,\mathrm{mov}}\) is reported in Table 1 (Color figure online)

Example of direction vector for cell movement. The width of each bin is computed following (7)

In order to determine the cell’s movement direction, the average porosity \(p_{\mathrm{avg},k}\) is calculated on the nodes of the computational grid covered by the cell (direction \(k=\mathbf {\varnothing }\)) and in the eight neighborhoods exterior to the cell, as depicted in Fig. 12. The outer diameter of the annulus \(a_{d,\mathrm{mov}}\) represents how far the cell is able to detect gradients in porosity, and it is chosen in this work to be six times the baseline cell movement (\(6d_\mathrm{cell}=3c_d\)) in one iteration. If the region k contains a grid point with porosity less than \(\epsilon _{p}\), which corresponds to an unfavorable region since there is not enough room for the cell, we set \(p_{\mathrm{avg},k}=0\).

The average values of porosity are then normalized in a probability direction vector where higher porosity will correspond to a higher probability in the porosity direction vector. The width of each bin \(\omega _{p,k}\), as shown in Fig. 13, corresponds to the probability of moving in each of the directions and is computed as

The movement direction of each cell is determined by choosing a distinct random variable X from a uniform distribution U[0, 1] and determining which direction bin contains \(\texttt {X}\). We note that wide bins \({\omega }_{p,k}\) have a higher probability of containing X and have larger width due to a more favorable porosity (larger \(p_{\mathrm{avg},k}\)). As an example of how the direction is chosen, if X=0.35 and the bin sizes are \({\omega }_{\mathbf {\varnothing }}=0.1\), \({\omega }_E=0.1\), and \({\omega }_{NE}=0.2\), X will fall in the NE bin (since \(0.1+0.1+0.2=0.4\)), therefore the corresponding cell will move in the NE direction or \(\theta _m=\pi /4\). We use the convention that the chosen cell direction k is the first direction to satisfy the following inequality: X\(<\left( \sum _{j=\varnothing }^{k}{\omega }_j\right) \) for \(k={\mathbf {\varnothing }},E,\ldots ,SE\). We note that if X\(=1\), this will correspond to \(k=SE\). At a given time step, all cells will simultaneously move in the chosen direction k by the corresponding angle \(\theta _m\) and a fixed distance \(d_\mathrm{cell}\) (reported in Table 1). Note that if cell movement results in a local porosity with \(p>1\), which may occur on occasion when multiple cells have moved into the same location, this issue is resolved by randomly choosing to undo the movement of half of these cells, until the situation is resolved.

1.3 Dividing Cells

To identify the cells that could potentially divide, we first determine the average porosity and nutrient concentration, \(p_\mathrm{avg}\) and \(c_\mathrm{avg}\), of the nodes in between the cell and the outer annulus with radius of \(a_{d,div}\) (refer to Fig. 12 for a schematic). The cells that have the potential to divide (passing conditions listed in Sect. 2.1.1, i.e., \(p_\mathrm{avg}>\epsilon _p\) and \(c_\mathrm{avg}>c_\mathrm{div}\)) undergo an overcrowding check to ensure that there is room for the new daughter cell. If an area is not overcrowded, the cell will divide. A crowded region is defined as dividing cells with center-to-center distance less than \(d_\mathrm{div}\) apart. For the cells in crowded regions, half are chosen at random and are allowed to undergo cell division where the new daughter cells are the same size as the dividing cell. This check prevents too many cells that are close to each other from dividing during the same iteration. The new cell is placed adjacent to the mother cell along a direction \(\theta _d\) that is a biased random function of the local porosity. The procedure used to determine the division direction vector is similar to the one followed to generate the porosity direction vector. The number of possible directions is reduced from 8 to 6 (E, NE, NW, W, SW, SE, each with an arc of \(\pi /3\)). We emphasize that this reduced number of regions is utilized based on a spatial argument; the six regions are able to contain the full surface of the new cell and this reduces overlap of daughter cells from nearby cells that are proliferating. The width of the six bins is

and the width of a bin is set to zero if the corresponding region contains a grid point with porosity such that \(p<\epsilon _{p}\). Similarly, we follow the same procedure used for cell movement where we choose a uniform variable X for each mother cell and find the bin and direction that will determine the position of the new (daughter) cell. The region where the average porosity is calculated, similar to the one depicted in Fig. 12, has outer diameter \(a_{d,div}\). We choose \(a_{d,div}=3.75c_d\) (i.e., outer radius of \(1.875c_d\)) since a gap of one grid point between the mother cell and the new cell is needed to avoid overlaps during cell division. Thus, the new daughter cell will be located at a radial distance of \(5c_d/4\) in the chosen direction where the 5/4 ensures that these cells are close but will not automatically go into the collision state. We emphasize that Eq. (8) provides a stronger bias than (7) resulting in a high probability that the new cell will be placed in a region of high porosity.

1.4 Discretization, Initialization and Boundaries for Continuous Variables

The porosity and nutrient are continuous variables that are calculated on a computational grid with a step size \(\triangle x=\triangle y=c_d/8\), i.e., the grid is considerably smaller than the cellular diameter to guarantee an accurate description of the continuous quantities and convergence of numerical results. This ensures that cells are able to bias motion and cell division in regions where there is a rapid transition in the magnitude of the porosity and/or nutrient. Since the porosity is \(p=1-\varPhi \), we must compute each of the solid volume fractions on the grid. Figure 14a shows a cell volume calculation where there is partial overlap of cells on the grid and 14b shows how the final solid volume fraction is determined, accounting for scaffold and ECM solid volume fractions. As described in Sect. 2.2.1, we assume a nutrient profile representative of a fixed nutrient concentration at the right and bottom portion of the construct that is exposed to the nutrient-rich medium and no-flux boundary conditions are assumed at the top and left side of the construct. The initial nutrient profile is high through the entire construct. For the porosity, we are solving differential equations for ECM and scaffold as given in Sect. 2.2.2 at each of the grid points and hence we do not apply boundary conditions. We assume that the scaffold is a given solid volume fraction at time zero, \(\varPhi _{SC}^0\), with values based on experiments (Freed et al. 1994; Erickson et al. 2009). We also assume zero ECM is formed at the start of the experiment, \(\varPhi _{ECM}^0=0\).

Examples of solid volume fractions for different components in the model. a The cellular solid volume fraction \(\varPhi _\mathrm{cell}\) is shown for the case where we assume each cell contributes \({\widehat{\varPhi }}=0.3\) to the solid volume fraction. b Total solid volume fraction \({\varPhi =\varPhi _\mathrm{cell}+\varPhi _{SC}+\varPhi _{ECM}}\) for the same cellular locations with \(\varPhi _{SC}+\varPhi _{ECM}=0.1\). The domain \(\varOmega \) assumes a thickness that allows for partial overlap of cells and for scaffold and/or extracellular matrix around the cells

Cell Aggregates

We use the built in function cluster in MATLAB to determine the size and distribution of cell aggregates within the construct. An example of a small- and large-cell aggregate is given in Fig. 15. In this work, a cell aggregate is defined as a group of three or more cells where the center-to-center distance to a subset of cells in the aggregate is less than \(1.75c_d\). This threshold value is selected to account for cells shapes that might not be perfectly spherical (Buxton et al. 2007; Hauselmann et al. 1992; Kino-oka et al. 2005). This choice of distance and the minimum count of three cells per aggregate also avoids that a cell and its daughter cell will be considered as an aggregate.

Aleatory Uncertainty Analysis

The model contains several stochastic elements that introduce aleatory uncertainty in each simulation. It is therefore necessary to perform an uncertainty quantification procedure to determine the minimum number of simulations to account for the full variation of the system (Alden et al. 2013; Cosgrove et al. 2015; Read et al. 2012). First, 20 sets of k simulations each with the same parameters are gathered. Then, sets 2–20 are compared with set 1 using the A-Test developed by Vargha and Delaney (2000). The A-Test returns an A-score for each comparison which represents the probability that a randomly selected sample from the first population is larger than a random sample from the second population. The A-score for the comparison between set a and b, \(A_{a,b}\) is computed following the approximation proposed in Vargha and Delaney (2000) as:

where \(\#(X_i>Y_j)\) counts the number of times the event \((X_i>Y_j)\) happens for all the \(X_i\) in set a and \(Y_j\) in set b and similarly \(\#(X_i=Y_j)\) counts the number of times the event \((X_i=Y_j)\) happens, and \(k_a\) and \(k_b\) are the dimension of set a and b, respectively. The A-score is used to determine statistical significance as follows: a score below 0.29 or above 0.71 indicates a large effect of sample size k on the model results; a score of 0.36 or 0.64 indicates a medium effect of k on model results; a score within 0.44 and 0.56 indicates a small effect of k on model results, and a score of 0.5 indicates no effect of k on model results. Figure 16 shows the results obtained for sample size \(k=300\) considering the final number of cells as the variable of interest, for simulations with the baseline parameters in Table 1 with \(\varPhi _{SC}^0=0.01\). Twenty groups with \(k=\)300 distinct simulations are obtained and then the A-score \(A_{1,j}\) is computed for \(j=1,\ldots ,20\) and reported in Fig. 16. The results obtained, with all of the A-scores within the [0.44, 0.56] interval, show that a value of 300 simulations is sufficient to mitigate the uncertainty introduced by the stochasticity of the model. The correct application of the A-Test is validated by the first point in Fig. 16, where the comparison of sample 1 with itself results in an A-score \(A_{1,1}=0.5\) as expected from the literature.

A-score \(A_{1,j}\) for comparison of set 1 with set \(j=1,\ldots ,20\) on the variable final number of cells in simulations with \(\varPhi _{SC}^0=0.01\) and parameters from Table 1 (Color figure online)

Rights and permissions

About this article

Cite this article

Cassani, S., Olson, S.D. A Hybrid Model of Cartilage Regeneration Capturing the Interactions Between Cellular Dynamics and Porosity. Bull Math Biol 82, 18 (2020). https://doi.org/10.1007/s11538-020-00695-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11538-020-00695-1