Abstract

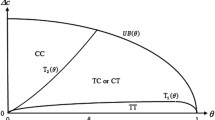

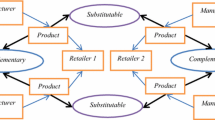

This paper investigates the strategic cooperation of two competitive suppliers with different abilities and a weak main manufacturer in Complex Products Systems (CoPS), where a main manufacturer signs a revenue-sharing contract based on a relationship-specific investment with the stronger supplier. The stronger supplier provides one key element to the main manufacturer and encroaches on the downstream market by producing substitutable final products simultaneously. We consider multi-period decisions, by building different models based on centralized, decentralized, and cooperative decisions. The equilibrium strategies are characterized under downstream competition, and optimal cooperation strategies are derived by building multi-period game models. The results show that strong cooperation can enhance the economic performance of each individual as well as the whole supply chain. The weak main manufacturer would face the risk of strong suppliers’ supply interruptions when the competitive degree of suppliers and downstream competition are fierce enough under decentralized decisions. Additionally, the gap in the abilities of the two competitive suppliers reduces the main manufacturer’s profitability. However, the revenue-sharing contract based on a relationship-specific investment can motivate the strong supplier to establish cooperation relationship and improve both stakeholders’ profitability. Moreover, strategic cooperation is efficient to prevent the strong supplier encroaching on downstream and has a positive impact on boosting the weak main manufacturer’s market share. Meanwhile, nurturing a domestic supplier is an effective measure for improving competitiveness and indigenous technological capability of the main manufacturer in CoPS. Finally, some useful management sights on cooperation strategy and optimal decisions are derived.

Similar content being viewed by others

References

Abegglen JC (1994). Sea Change: Pacific Asia as the New World Industrial Centre. The Free Press, New York: 207–211.

Arya A, Mittendorf B, Sappington DE (2007). The bright side of supplier encroachment. Marketing Science 26(5): 651–659.

Chang HL, Wu JG (2015). Exploring company ability to meet supply chain security validation criteria. International Journal of Physical Distribution & Logistics Management 45(7): 691–710.

Chiang WYK, Chhajed D, Hess JD (2003). Direct marketing, indirect profits: A strategic analysis of dual-channel supply-chain design. Management Science 49(1):1–20.

Choung JY, HR Hwang (2007). Developing the complex system in Korea: The case study of TDX and CDMA telecom system. International Journal of Technological Learning, Innovation and Development 1(2): 204–225.

Cohen-Vernik D, Purohit D (2014). Turn-and-earn incentives with a product line. Management Science 60(2):400–414.

Cooper R, Ross TW (1985). Product warranties and double moral hazard. The Rand Journal Of Economics: 103–113.

Crawford VP (1990). Relationship-specific investment. The Quarterly Journal of Economics 105(2): 561–574.

Davies A (1997), The life cycle of acomplex product system. International Journal of Innovation Management 1(3): 229–256.

Dedehayir O, Nokelainen T, Mkinen SJ (2014). Disruptive innovations in complex product systems industries: A case study. Journal of Engineering and Technology Management 33: 174–192.

Du B, Guo S (2016). Production planning conflict resolution of complex product system in group manufacturing: A novel hybrid approach using ant colony optimization and shapley value. Computers & Industrial Engineering 94: 158–169.

Feng Q, Lu LX (2013). Supply chain contracting under competition: Bilateral bargaining vs. Stackelberg. Production and Operations Management 22(3): 661–675.

Frischtak CR (1994). Learning and technical progress in the commuter aircraft industry: An analysis of Embraer’s experience. Research Policy 23(5): 601–612.

Govindan K, Popiuc MN (2014). Reverse supply chain coordination by revenue sharing contract: A case for the personal computers industry. European Journal of Operational Research 233(2): 326–336.

Guan H, Gurnani H, Geng X, Luo Y (2018). Strategic Inventory and Supplier Encroachment. Manufacturing & Service Operations Management 7: 1–20.

Gurnani H, Erkoc M (2008). Supply contracts in manufacturer-retailer interactions with manufacturer quality and retailer effort induced demand. Naval Research Logistics 55(3): 200–217.

Heydari J, Rastegar M, Glock CH (2017). A two-level delay in payments contract for supply chain coordination: The case of credit-dependent demand. International Journal of Production Economics 191: 26–36.

Hobday M (1998). Product complexity, innovation and industrial organization. Research Policy 26: 689–710.

Hsu JSC, Hung YW, Shih SP, Hsu HM (2016). Expertise coordination in information systems development projects: Willingness, ability, and behavior. Project Management Journal 47(4): 95–115.

Huang S, Guan X, Chen YJ (2018). Retailer information sharing with supplier encroachment. Production and Operations Management 27(6): 1133–1147.

Ivanov, Dmitry, Ajay Das, Tsan Ming Choi (2018). New flexibility drivers for manufacturing, supply chain and service operations. International Journal of Production Research 56: 1–10.

Ji G, Han S, Tan KH (2018). False failure returns: optimal pricing and return policies in a dual-channel supply chain. Journal of Systems Science and Systems Engineering 27(3): 292–321.

Kato W, Arizono I, Takemoto Y (2018). A proposal of bargaining solution for cooperative contract in a supply chain. Journal of Intelligent Manufacturing 29(3):559–567.

Kaya M, Özer (2009). Quality risk in outsourcing: Noncontractible product quality and private quality cost information. Naval Research Logistics 56(7): 669–685.

Kraft K (2018). Productivity and distribution effects of codetermination in an efficient bargaining model. International Journal of Industrial Organization 59: 458–485.

Lee JJ, Yoon H (2015). A comparative study of technological learning and organizational capability development in complex products systems: Distinctive paths of three latecomers in military aircraft industry. Research Policy 44(7): 1296–1313.

Liang L, Xie J, Liu L, Xia Y (2017). Revenue sharing contract coordination of wind turbine order policy and aftermarket service based on joint effort. Industrial Management & Data Systems 117(2): 320–345.

Lu L, Lariviere M (2012). Capacity allocation over a long horizon: The return on turn-and-earn. Manufacturing and Service Operations Management 14 (1): 24–41.

Lu Y, Xu M, Yu Y (2018). Coordinating pricing, ordering and advertising for perishable products over an infinite horizon. Journal of Systems Science and Systems Engineering 27(1): 106–129.

Ma, Q, Wang W, Peng Y, Song X (2018). A two-stage stochastic optimization model for port cold storage capacity allocation considering pelagic fishery yield uncertainties. Engineering Optimization: 1–15.

Nouri M, Hosseini-Motlagh SM, Nematollahi M, Sarker BR (2018). Coordinating manufacturer’s innovation and retailer’s promotion and replenishment using a compensation-based wholesale price contract. International Journal of Production Economics 198(C): 11–24.

Park TY (2012). How a latecomer succeeded in a complex product system industry: Three case studies in the Korean telecommunication systems. Industrial and Corporate Change 22(2): 363–396.

Qing Q, Deng T, Wang H (2017). Capacity allocation under downstream competition and bargaining. European Journal of Operational Research 261 (1): 97–107.

Rangan VK, Menezes MA, Maier EP (1992). Channel selection for newindustrial products: Aframework, method, and application. The Journal of Marketing: 69–82.

Salmani Y, Partovi FY, Banerjee A (2018). Customer-driven investment decisions in existing multiple sales channels: A downstream supply chain analysis. International Journal of Production Economics 204: 44–58.

Sandonís J, López-Cuñat JM (2018). Upstream incentives to encourage downstream competition in a vertically separated industry. The Singapore Economic Review 63(03): 619–627.

Smith DJ, Tranfield D (2005). Talented suppliers? Strategic change and innovation in the UK aerospace industry. R & D Management 35(1): 37–49.

Steward MD, Wu Z, Hartley JL (2010). Exploring supply managers’ intrapreneurial ability and relationship quality. Journal of Business-to-Business Marketing 17(2): 127–148.

Trivedi M (1998). Distribution channels: An extension of exclusive retailer-ship. Management Science 44(7): 896–909.

Vasconcelos L (2014). Contractual signaling, relationship-specific investment and exclusive agreements. Games and Economic Behavior 87: 19–33.

Vázquez-Casielles R, Iglesias V, Varela-Neira C (2017). Manufacturer — distributor relationships: Role of relationship-specific investment and dependence types. Journal of Business & Industrial Marketing 32(8): 1245–1260.

Warren-Myers G, Heywood C (2016). Investigating demand-side stakeholders’ ability to mainstream sustainability in residential property. Pacific Rim Property Research Journal 22(1): 59–75.

Weisman D, Kang J (2001). Incentives for discrimination when upstream monopolists participate in downstream markets. Journal of Regulatory Economics 20 (2): 125–139.

Yang H, Luo J, Zhang Q (2018). Supplier encroachment under nonlinear pricing with imperfect substitutes: Bargaining power versus revenue-sharing. European Journal of Operational Research 267(3): 1089–1101.

Yang L, Wang G, Chai Y (2018). Manufacturer’s channel selection considering carbon emission reduction and remanufacturing. Journal of Systems Science and Systems Engineering 27(4): 497–518.

Yu X, Lan Y, Zhao R (2018). Cooperation royalty contract design in research and development alliances: Help vs. knowledge-sharing. European Journal of Operational Research 268(2): 740–754.

Zhu X, Wang J, Tang J (2017). Recycling pricing and coordination of WEEE dual-channel closed-loop supply chain considering consumers’ bargaining. International Journal of Environmental Research and Public Health 14(12): 1578.

Ziss S (1995). Vertical separation and horizontal mergers. The Journal of Industrial Economics: 63–75.

Acknowledgments

The authors really appreciate the editors and the referees for their valuable comments and suggestions that have greatly improved this article. This work was partially supported by the National Natural Science Foundation of China under Grant Nos.71171112 and 71502073, the Postgraduate Research and Practice Innovation Program of Jiangsu Province under Grant KYCH17_0223 and China scholarship council under Grant No.201806830048.

Author information

Authors and Affiliations

Corresponding author

Additional information

Jinhua Zhou is is a PhD candidate in the College of Economics and Management at Nanjing University of Aeronautics and Astronautics. She received her BS and MS degree in management science and engineering at Lanzhou University of Technology in 2013 and 2016 respectively. Her research interests are supply chain management, game theory, and modeling on complex product systems. Her research papers have been published in journals including Control and Decision, International Journal of Simulation-Systems, Science & Technology, etc.

Jianjun Zhu is a professor in the College of Economics and Management at Nanjing University of Aeronautics and Astronautics. He received his PhD degree in system engineering at Northeastern University. His research interests are supply chain management, decision making, and modeling on complex product systems. His research papers have been published in journals including Information Science, Information Fusion, etc.

Hehua Wang is a lecturer in the School of Business at Jinling Institute of Technology. She received his PhD degree in management science and engineering at Nanjing University of Aeronautics and Astronautics. Her research interests are supply chain management, decision making, and modeling on complex product systems. Her research papers have been published in journals including Control and Decision, Information Science, etc.

Rights and permissions

About this article

Cite this article

Zhou, J., Zhu, J. & Wang, H. Strategic Cooperation with Differential Suppliers’ Ability under Downstream Competition in Complex Products Systems. J. Syst. Sci. Syst. Eng. 28, 449–477 (2019). https://doi.org/10.1007/s11518-019-5422-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11518-019-5422-z