Abstract

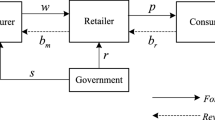

In this paper, we consider a single-period model comprised of an original manufacturer (OM) who produces only new products and a remanufacturer who collects used products from consumers and produces remanufactured products. The OM and the remanufacturer compete in the product market. We examine the effects of government subsidy as a means to promote remanufacturing activity. In particularly, we consider three subsidy options: subsidy to remanufacturer, subsidy to consumers, and subsidy shared by remanufacturer and consumers. We find that the introduction of government subsidy on remanufacturer or consumers always increases remanufacturing activity. We also find that subsidy to remanufacturer is the best subsidy option, because subsidy to remanufacturer results in lower price of remanufactured products, thus leading to higher consumer surplus.

Similar content being viewed by others

References

Aksen, D., Aras, N. & Karaarslan, A. G. (2009). Design and analysis of government subsidized collection systems for incentive-dependent returns. International Journal of Production Economics, 119(2): 308–327.

Arunkundram, R. & Sundararajan, A. (1998). An economic analysis of electronic secondary markets: installed base, technology, durability and firm profitability. Decision Support Systems, 24(1): 3–16.

Atasu, A., Sarvary, M. & Van Wassenhove, L. N. (2008). Remanufacturing as a marketing strategy. Management Science, 54(10): 1731–1746.

Bulmus, S. C., Zhu, S. X. & Teunter, R. (2014). Competition for cores in remanufacturing. European Journal of Operational Research, 233(1): 105–113.

Ferguson, M. E. & Toktay, L. B. (2006). The effect of competition on recovery strategies. Production and Operations Management, 15(3): 351.

Fleischmann, M., BloemhofRuwaard, J. M., Dekker, R., vanderLaan, E., vanNunen, J. & VanWassenhove, L. N. (1997). Quantitative models for reverse logistics: a review. European Journal of Operational Research, 103(1): 1–17.

Giutini, R. & Gaudette, K. (2003). Remanufacturing: the next great opportunity for boosting US productivity. Business Horizons, 46(6): 41–48.

Guide, V. D. R. & Van Wassenhove, L. (2002). Closed-Loop Supply Chains. Springer: Berlin, Germany.

Guide, V. D. R. & Van Wassenhove, L. N. (2009). OR FORUM -the evolution of closed-loop supply chain research. Operations Research, 57(1): 10–18.

Gutowski, T., Murphy, C., Allen, D., Bauer, D., Bras, B., Piwonka, T., Sheng, P., Sutherland, J., Thurston, D. & Wolff, E. (2005). Environmentally benign manufacturing: observations from Japan, Europe and the United States. Journal of Cleaner Production, 13(1): 1–17.

Hammond, D. & Beullens, P. (2007). Closed-loop supply chain network equilibrium under legislation. European Journal of Operational Research, 183(2): 895–908.

HKEPD. (2015). Hong Kong Waste Reduction Website. Via https://www.wastereduction.gov.hk/sc/quickaccess/stat_recycle.htm.

Hong, I. H. & Ke, J. S. (2011). Determining advanced recycling fees and subsidies in "E-scrap" reverse supply chains. J Environ Manage, 92(6): 1495–1502.

Ma, W.-m., Zhao, Z. & Ke, H. (2013). Dual-channel closed-loop supply chain with government consumption-subsidy. European Journal of Operational Research, 226(2): 221–227.

Majumder, P. & Groenevelt, H. (2001). Competition in remanufacturing. Production and Operations Management, 10(2): 125–141.

Miao, Z., Mao, H., Fu, K. & Wang, Y. (2016). Remanufacturing with trade-ins under carbon regulations. Computers & Operations Research. Available via http://dx.doi.org/10.1016/j.cor.2016.03.014.

Mitra, S. & Webster, S. (2008). Competition in remanufacturing and the effects of government subsidies. International Journal of Production Economics, 111(2): 287–298.

Pokharel, S. & Mutha, A. (2009). Perspectives in reverse logistics: a review. Resources Conservation & Recycling, 53(4): 175–182.

Savaskan, R. C., Bhattacharya, S. & Van Wassenhove, L. N. (2004). Closed-loop supply chain models with product remanufacturing. Management Science, 50(2): 239–252.

Savaskan, R. C. & Van Wassenhove, L. N. (2006). Reverse channel design: the case of competing retailers. Management Science, 52(1): 1–14.

Sheu, J.-B. & Chen, Y. J. (2012). Impact of government financial intervention on competition among green supply chains. International Journal of Production Economics, 138(1): 201–213.

Thierry, M., Salomon, M., Van Nunen, J. & Van Wassenhove, L. (1995). Strategic issues in product recovery management. California Management Review, 37(2): 114–135.

Toktay, L. B., Wein, L. M. & Zenios, S. A. (2000). Inventory management of remanufacturable products. Management Science, 46(11): 1412–1426.

Vorasayan, J. & Ryan, S. M. (2006). Optimal price and quantity of refurbished products. Production and Operations Management, 15(3): 369–383.

Wang, K., Zhao, Y., Cheng, Y. & Choi, T.-M. (2014). Cooperation or competition? channel choice for a remanufacturing fashion supply chain with government subsidy. Sustainability, 6(10): 7292–7310.

Webster, S. & Mitra, S. (2007). Competitive strategy in remanufacturing and the impact of take-back laws. Journal of Operations Management, 25(6): 1123–1140.

Wu, C.-H. (2012). Price and service competition between new and remanufactured products in a two-echelon supply chain. International Journal of Production Economics, 140(1): 496–507.

Zhang, X.-x., Xu, T.-t. & Zhang, H. (2013). Coordination of closed-loop supply chain with government incentive. 2013 International Conference on Management Science and Engineering (ICMSE), IEEE.

Acknowledgments

The authors thank the anonymous referees for their comments and suggestions. This research was supported by the Natural Science Foundation of China (Nos.71231007, 71373222, 71501149).

Author information

Authors and Affiliations

Corresponding author

Additional information

Lu Xiao is a Ph.D. candidate in School of Economics and Management at Wuhan University and Department of Systems Engineering and Engineering Management at City University of Hong Kong. She received her Bachelor Degree in management from Wuhan University in 2012. Her research interests are in the areas of remanufacturing, game theory, supply chain and operations management.

Xianjia Wang is a professor of the School of Economics and Management at Wuhan University. He received his Bachelor Degree in applied mathematics from Wuhan University in 1982, and PhD in systems engineering from Wuhan University in 1992. His research interests are in the areas of game theory, mechanism design, supply chain and operations management.

Kwai-Sang Chin is Associate Head and Associate Professor of Department of Systems Engineering and Engineering Management at City University of Hong Kong. He received his MSc(Engg) in industrial engineering from the University of Hong Kong in 1990, PhD in industrial engineering from the University of Hong Kong in 1996. He published over 200 journal papers and refereed conference papers, authored 8 books/book chapters, edited 4 books, and gave numerous invited talks and presentations. His research interests are in the areas of remanufacturing, quality management and decision analysis.

Yong Qin is an instructor at Xiangyang Sergent School of Military Economy Academy. He received his Master Degree in systems engineering from Wuhan University in 2014. His research interests are in the areas of evaluation and decision analysis.

Rights and permissions

About this article

Cite this article

Xiao, L., Wang, X., Chin, KS. et al. Competitive strategy in remanufacturing and the effects of government subsidy. J. Syst. Sci. Syst. Eng. 26, 417–432 (2017). https://doi.org/10.1007/s11518-017-5345-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11518-017-5345-5