Abstract

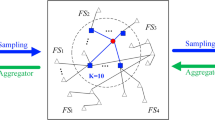

Existing fault diagnosis methods usually assume that there are balanced training data for every machine health state. However, the collection of fault signals is very difficult and expensive, resulting in the problem of imbalanced training dataset. It will degrade the performance of fault diagnosis methods significantly. To address this problem, an imbalanced fault diagnosis of rotating machinery using autoencoder-based SuperGraph feature learning is proposed in this paper. Unsupervised autoencoder is firstly used to compress every monitoring signal into a low-dimensional vector as the node attribute in the SuperGraph. And the edge connections in the graph depend on the relationship between signals. On the basis, graph convolution is performed on the constructed SuperGraph to achieve imbalanced training dataset fault diagnosis for rotating machinery. Comprehensive experiments are conducted on a benchmarking publicized dataset and a practical experimental platform, and the results show that the proposed method can effectively achieve rotating machinery fault diagnosis towards imbalanced training dataset through graph feature learning.

Similar content being viewed by others

Abbreviations

- AE:

-

Autoencoder-based extraction

- AG:

-

Affinity graph-based GCN

- CNN:

-

Convolutional neural network

- FFT:

-

Fast Fourier transform

- GAN:

-

Generative adversarial network

- GCN:

-

Graph convolutional network

- RD:

-

Raw data

- ReLU:

-

Rectified linear unit

- TF:

-

Traditional feature-based extraction

- VIG:

-

Vibration indicator-based GCN

- A :

-

Adjacency matrix

- b, d :

-

Bias vectors

- Cheb :

-

Function of Chebyshev graph convolution

- D :

-

Degree matrix

- E :

-

Edge set

- e θ :

-

Encoding function of autoencoder

- f k :

-

Frequency value of kth spectral line

- F :

-

Feature vector

- g θ′ :

-

Decoding function of autoencoder

- G :

-

Undirected graph

- H, F, J :

-

Scales of graph convolution layer

- h (i) :

-

Output of hidden layer of autoencoder

- I n :

-

Identity matrix

- K :

-

Chebyshev polynomial coefficient

- L :

-

Reconstruction error

- L :

-

Laplacian matrix

- Loss :

-

Loss function of autoencoder

- m, M :

-

Number of elements in vector

- N :

-

Number of nodes

- s f, s g :

-

Sigmoid function of encoder and decoder, respectively

- T k :

-

Chebyshev polynomial

- u i (i = 1, 2, …, n):

-

Eigenvector

- U :

-

Eigenvector matrix

- V :

-

Node set of graph

- W :

-

Weight matrix

- W ′ :

-

Parameterized weight matrix

- x(n):

-

Data point of time-domain signal x

- X :

-

Input signal

- X′:

-

Output of Chebyshev graph convolution layer

- x (i) :

-

Input of encoder

- y(k):

-

Frequency spectrum of x

- y (i) :

-

Output of decoder

- Y :

-

Output of filter operation in GCN

- Z :

-

Label of samples

- σ :

-

Activation function of ReLU

- θ, θ′ :

-

Parameter sets of encoder

- θ k :

-

Chebyshev coefficient

- Λ :

-

Eigenvalue matrix of Laplacian matrix

- Λ̃ :

-

normalized version of Λ

- λ :

-

Eigenvalue

- λ max :

-

Largest element of Λ

- φ θ :

-

Filter function of GCN

- ϕ AE :

-

Reconstruction error of autoencoder

References

Shao H, Jiang H, Wang F, et al. An enhancement deep feature fusion method for rotating machinery fault diagnosis. Knowledge-Based Systems, 2017, 119: 200–220

Han T, Liu C, Wu L, et al. An adaptive spatiotemporal feature learning approach for fault diagnosis in complex systems. Mechanical Systems and Signal Processing, 2019, 117: 170–187

Lei Y, Jia F, Lin J, et al. An intelligent fault diagnosis method using unsupervised feature learning towards mechanical Big Data. IEEE Transactions on Industrial Electronics, 2016, 63(5): 3137–3147

Chen Z, Mauricio A, Li W, et al. A deep learning method for bearing fault diagnosis based on cyclic spectral coherence and convolutional neural networks. Mechanical Systems and Signal Processing, 2020, 140: 106683

Han T, Li Y, Qian M. A hybrid generalization network for intelligent fault diagnosis of rotating machinery under unseen working conditions. IEEE Transactions on Instrumentation and Measurement, 2021, 70: 1–11

Guo X, Chen L, Shen C. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Measurement, 2016, 93: 490–502

Ren H, Liu W, Shan M, et al. A new wind turbine health condition monitoring method based on VMD-MPE and feature-based transfer learning. Measurement, 2019, 148: 106906

Razavi-Far R, Hallaji E, Farajzadeh-Zanjani M, et al. A semisupervised diagnostic framework based on the surface estimation of faulty distributions. IEEE Transactions on Industrial Informatics, 2019, 15(3): 1277–1286

Chen F, Tang B, Chen R. A novel fault diagnosis model for gearbox based on wavelet support vector machine with immune genetic algorithm. Measurement, 2013, 46(1): 220–232

Chen Z, Mauricio A, Li W, et al. A deep learning method for bearing fault diagnosis based on Cyclic Spectral Coherence and Convolutional Neural Networks. Mechanical Systems and Signal Processing, 2020, 140: 106683

Mao W, He L, Yan Y, et al. Online sequential prediction of bearings imbalanced fault diagnosis by extreme learning machine. Mechanical Systems and Signal Processing, 2017, 83: 450–473

Dai X, Gao Z. From model, signal to knowledge: a data-driven perspective of fault detection and diagnosis. IEEE Transactions on Industrial Informatics, 2013, 9(4): 2226–2238

Zhang Y, Li X, Gao L, et al. Imbalanced data fault diagnosis of rotating machinery using synthetic oversampling and feature learning. Journal of Manufacturing Systems, 2018, 48: 34–50

Barandela R, Valdovinos R M, Sánchez J S, et al. The imbalanced training sample problem: Under or over sampling? In: Fred A, Caelli T M, Duin R P W, et al., eds. Structural, Syntactic, and Statistical Pattern Recognition. Berlin: Springer, 2004, 806–814

Guo L, Lei Y, Xing S, et al. Deep convolutional transfer learning network: a new method for intelligent fault diagnosis of machines with unlabeled data. IEEE Transactions on Industrial Electronics, 2019, 66(9): 7316–7325

Yang B, Lei Y, Jia F, et al. An intelligent fault diagnosis approach based on transfer learning from laboratory bearings to locomotive bearings. Mechanical Systems and Signal Processing, 2019, 122: 692–706

Li X, Zhang W, Ding Q. A robust intelligent fault diagnosis method for rolling element bearings based on deep distance metric learning. Neurocomputing, 2018, 310: 77–95

Mariani G, Scheidegger F, Istrate R, et al. BAGAN: Data Augmentation with Balancing GAN. 2018, arXiv:1803.09655

Zhang W, Li X, Jia X, et al. Machinery fault diagnosis with imbalanced data using deep generative adversarial networks. Measurement, 2020, 152: 107377

Gao X, Deng F, Yue X. Data augmentation in fault diagnosis based on the Wasserstein generative adversarial network with gradient penalty. Neurocomputing, 2020, 396: 487–494

Zhao X, Jia M, Lin M. Deep Laplacian auto-encoder and its application into imbalanced fault diagnosis of rotating machinery. Measurement, 2020, 152: 107320

Jia F, Lei Y, Lu N, et al. Deep normalized convolutional neural network for imbalanced fault classification of machinery and its understanding via visualization. Mechanical Systems and Signal Processing, 2018, 110: 349–367

Wang T, Liu Z, Lu G, et al. Temporal-spatio graph based spectrum analysis for bearing fault detection and diagnosis. IEEE Transactions on Industrial Electronics, 2021, 68(3): 2598–2607

Lo C H, Wong Y K, Rad A B, et al. Fusion of qualitative bond graph and genetic algorithms: a fault diagnosis application. ISA Transactions, 2002, 41(4): 445–456

Wang T, Lu G, Yan P. A novel statistical time-frequency analysis for rotating machine condition monitoring. IEEE Transactions on Industrial Electronics, 2020, 67(1): 531–541

Gao Y, Yu D. Total variation on horizontal visibility graph and its application to rolling bearing fault diagnosis. Mechanism and Machine Theory, 2020, 147: 103768

Yang C, Zhou K, Liu J. SuperGraph: Spatial-temporal graph-based feature extraction for rotating machinery diagnosis. IEEE Transactions on Industrial Electronics, 2021 (in press)

Zhang D, Stewart E, Entezami M, et al. Intelligent acoustic-based fault diagnosis of roller bearings using a deep graph convolutional network. Measurement, 2020, 156: 107585

Wang S, Xing S, Lei Y, et al. Vibration indicator-based graph convolutional network for semi-supervised bearing fault diagnosis. IOP Conference Series. Materials Science and Engineering, 2021, 1043(5): 052026

Wang Y, Gao L, Gao Y, et al. A new graph-based semi-supervised method for surface defect classification. Robotics and Computer-Integrated Manufacturing, 2021, 68: 102083

Liu J, Hu Y, Wang Y, et al. An integrated multi-sensor fusionbased deep feature learning approach for rotating machinery diagnosis. Measurement Science & Technology, 2018, 29(5): 055103

Tran V T, Althobiani F, Ball A. An approach to fault diagnosis of reciprocating compressor valves using Teager-Kaiser energy operator and deep belief networks. Expert Systems with Applications, 2014, 41(9): 4113–4122

Bengio Y, Courville A, Vincent P. Representation learning: a review and new perspectives. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2013, 35(8): 1798–1828

Erhan D, Bengio Y, Courville A, et al. Why does unsupervised pre-training help deep learning? Journal of Machine Learning Research, 2010, 11: 625–660

Shuman D I, Narang S K, Frossard P, et al. The emerging field of signal processing on graphs: extending highdimensional data analysis to networks and other irregular domains. IEEE Signal Processing Magazine, 2013, 30(3): 83–98

Song T, Zheng W, Song P, et al. Eeg emotion recognition using dynamical graph convolutional neural networks. IEEE Transactions on Affective Computing, 2020, 11(3): 532–541

Defferrard M, Bresson X, Vandergheynst P. Convolutional neural networks on graphs with fast localized spectral filtering. Advances in Neural Information Processing Systems, 2016, 29: 3844–3852

Shao S, McAleer S, Yan R, et al. Highly accurate machine fault diagnosis using deep transfer learning. IEEE Transactions on Industrial Informatics, 2019, 15(4): 2446–2455

Shao H, Jiang H, Zhao H, et al. A novel deep autoencoder feature learning method for rotating machinery fault diagnosis. Mechanical Systems and Signal Processing, 2017, 95: 187–204

Li T, Zhao Z, Sun C, et al. Multi-receptive field graph convolutional networks for machine fault diagnosis. IEEE Transactions on Industrial Electronics, 2020 (in press)

Acknowledgement

This work was supported by the National Key R&D Program of China (Grant No. 2020YFB1711203).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J., Zhou, K., Yang, C. et al. Imbalanced fault diagnosis of rotating machinery using autoencoder-based SuperGraph feature learning. Front. Mech. Eng. 16, 829–839 (2021). https://doi.org/10.1007/s11465-021-0652-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-021-0652-4