Abstract

This paper presents a survey of recent advancements and upcoming trends in motion control technologies employed in designing multi-actuator hydraulic systems for mobile machineries. Hydraulic systems have been extensively used in mobile machineries due to their superior power density and robustness. However, motion control technologies of multi-actuator hydraulic systems have faced increasing challenges due to stringent emission regulations. In this study, an overview of the evolution of existing throttling control technologies is presented, including open-center and load sensing controls. Recent advancements in energy-saving hydraulic technologies, such as individual metering, displacement, and hybrid controls, are briefly summarized. The impact of energy-saving hydraulic technologies on dynamic performance and control solutions are also discussed. Then, the advanced operation methods of multi-actuator mobile machineries are reviewed, including coordinated and haptic controls. Finally, challenges and opportunities of advanced motion control technologies are presented by providing an overall consideration of energy efficiency, controllability, cost, reliability, and other aspects.

Similar content being viewed by others

References

Stelson K A. Saving the world’s energy with fluid power. In: Proceedings of the 8th JFPS International Symposium on Fluid Power. Okinawa: JFPS, 2011, 25–28

Vukovic M. An overview of energy saving architectures for mobile applications. In: Proceedings of the 9th International Fluid Power Conference. Aachen, 2014, 374–385

Winck R C, Elton M, Book W J. A practical interface for coordinated position control of an excavator arm. Automation in Construction, 2015, 51: 46–58

Axin M. Fluid power systems for mobile applications:With a focus on energy efficiency and dynamic characteristics. Dissertation for the Doctoral Degree. Linköping: Linköping University, 2013

Weber J, Burget W. Mobile systems—Markets, industrial needs and technological trends. In: Proceedings of the 8th International Fluid Power Conference (IFK). Dresden, 2012, (2): 23–54

Krus P. On load sensing fluid power systems: With special reference to dynamic properties and control aspects. Dissertation for the Doctoral Degree. Linköping: Linköping University, 1988

Axin M, Eriksson B, Krus P. A flexible working hydraulic system for mobile machines. International Journal of Fluid Power, 2016, 17(2): 79–89

Wu D. Modeling and experimental evaluation of a load-sensing and pressure compensated hydraulic system. Dissertation for the Doctoral Degree. Saskatchewan: University of Saskatchewan, 2003

Pedersen H C, Andersen T O, Hansen M R. Load sensing systems—A review of the research contributions throughout the last decades. In: Proceedings of the 6th International Fluid Power Conference. Dresden, 2004, 125–137

Axin M, Eriksson B, Palmberg J O, et al. Dynamic analysis of single pump, flow controlled mobile systems. In: Proceedings of the 12th Scandinavian International Conference on Fluid Power. Tampere, 2011

Ding R, Xu B, Zhang J, et al. Self-tuning pressure-feedback control by pole placement for vibration reduction of excavator with independent metering fluid power system. Mechanical Systems and Signal Processing, 2017, 92: 86–106

Sun L. Modeling and control of a hydraulic system with multi actuators. Thesis for the Master’s Degree. West Lafayette: Purdue University, 2012

Lu L, Yao B. Energy-saving adaptive robust control of a hydraulic manipulator using five cartridge valves with an accumulator. IEEE Transactions on Industrial Electronics, 2014, 61(12): 7046–7054

Eriksson B, Palmberg J O. Individual metering fluid power systems: Challenges and opportunities. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2011, 225(2): 196–211

Linjama M. Digital fluid power: State of the art. In: Proceedings of 12th Scandinavian International Conference on Fluid Power. Tampere, 2011, 18–20

Scheidl R, Linjama M, Schmidt S. Is the future of fluid power digital? Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2012, 226(6): 721–723

Yang H, Pan M. Engineering research in fluid power: A review. Journal of Zhejiang University-Science A, 2015, 16(6): 427–442

Hansen A H, Pedersen H C. Reducing pressure oscillations in discrete fluid power systems. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2016, 230(10): 1093–1105

Heikkilä M, Linjama M. Improving damping characteristics of displacement controlled digital hydraulic system. In: Proceedings of the 5th Workshop on Digital Fluid Power. Tampere, 2012, 75–87

Hansen R H, Anderson T O, Pederson H C. Development and implementation of an advanced power management algorithm for electronic load sensing on a telehandler. In: Proceedings of Bath/ ASME Symposium on Fluid Power Motion Control. Bath, 2010, 537–550

Hansen R H, Iverson A M, Jensen MS, et al. Modeling and control of a teletruck using electronic load sensing. In: Proceedings of the ASME 10th Biennial Conference on Engineering Systems Design and Analysis. Istanbul: ASME, 2010, 769–778

The Drive & Control Company. Virtual bleed off VBO. Retrieved from https://www.boschrexroth.com/en/xc/products/productgroups/mobile-hydraulics/systems-and-functional-modules/virtual- bleed-off-vbo/index, 2017–2-28

Mettälä K, Djurovic M, Keuper G, et al. Intelligent oil flow management with EFM: The potentials of electrohydraulic flow matching in tractor hydraulics. In: Proceedings of the 10th Scandinavian International Conference on Fluid Power. Tampere, 2007, 25–34

Cheng M, Xu B, Liu W, et al. Study on the electrohydraulic flow matching control system with a bypass unloading valve. In: Proceedings of the 8th International Conference on Fluid Power Transmission and Control. Hangzhou, 2013

Grösbrink B, Harms H H. Alternating pump control for a loadsensing system. In: Proceedings of the 7th International Fluid Power Conference. Aachen, 2010

Cetinkunt S, Pinsopon U, Chen C, et al. Positive flow control of closed-center electrohydraulic implement-by-wire systems for mobile equipment applications. Mechatronics, 2004, 14(4): 403–420

Axin M, Eriksson B, Krus P. A hybrid of pressure and flow control in mobile hydraulic systems. In: Proceedings of the 9th International Fluid Power Conference. Aachen, 2014

Xu B, Liu W, Cheng M, et al. A new electrohydraulic load sensing control system for hydraulic excavators. In: Proceedings of the 8th International Fluid Power Conference. Dresden, 2012

Cheng M, Xu B, Yang H. Efficiency improvement for electrohydraulic flow sharing systems. In: Proceedings of the 9th International Fluid Power Conference. Aachen, 2014

Axin M, Eriksson B, Krus P. Flow versus pressure control of pumps in mobile hydraulic systems. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2014, 228(4): 245–256

Finzel R, Helduser S, Jang D. Electro-hydraulic dual-circuit system to improve the energy efficiency of mobile machines. In: Proceedings of the 6th International Fluid Power Conference. Aachen, 2010

Sitte A, Beck B, Weber J. Design of independent metering control systems. In: Proceedings of the 9th International Fluid Power Conference. Aachen, 2014, 428–440

Liu B, Quan L, Ge L. Research on the performance of hydraulic excavator boom based pressure and flow accordance control with independent metering circuit. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2016, 1–13

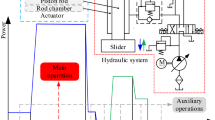

Xu B, Ding R, Zhang J, et al. Pump/valves coordinate control of the independent metering system for mobile machinery. Automation in Construction, 2015, 57: 98–111

Liu K, Gao Y, Tu Z. Energy saving potential of load sensing system with hydro-mechanical pressure compensation and independent metering. International Journal of Fluid Power, 2016, 17 (3): 173–186

Williamson C A. Power management for multi-actuator mobile machines with displacement controlled hydraulic actuators. Dissertation for the Doctoral Degree. West Lafayette: Purdue University, 2010

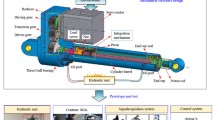

Busquets E, Ivantysynova M. The world’s first displacement controlled excavator prototype with pump switching—A study of the architecture and control. In: Proceedings of the 9th JFPS International Symposium on Fluid Power. Matsue, 2014, 324–331

Kim Y B, Kim P Y, Murrenhoff H. Boom potential energy regeneration scheme for hydraulic excavators. In: Proceedings of the BATH/ASME 2016 Symposium on Fluid Power and Motion Control. Bath, 2016

Busquets E, Ivantysynova M. Toward supervisory-level control for the energy consumption and performance optimization of displacement-controlled hydraulic hybrid machines. In: Proceedings of the 10th IFK International Conference on Fluid Power. Dresden, 2016

Heybroek K. Saving energy in construction machinery using displacement control hydraulics. Dissertation for the Doctoral Degree. Linköping: Linköping University, 2008

Sgro S, Inderelst M, Murrenhoff H. Energy efficiency of mobile working machines. In: Proceedings of the 7th International Fluid Power Conference. Aachen, 2010

Casoli P, Riccò L, Campanini F, et al. Hydraulic hybrid excavator—Mathematical model validation and energy analysis. Energies, 2016, 9(12): 1002

Lin T, Huang W, Ren H, et al. New compound energy regeneration system and control strategy for hybrid hydraulic excavators. Automation in Construction, 2016, 68: 11–20

Minav T A, Murashko K, Laurila L, et al. Forklift with a lithiumtitanate battery during a lifting/lowering cycle: Analysis of the recuperation capability. Automation in Construction, 2013, 35(14): 275–284

Chen M, Zhao D. The gravitational potential energy regeneration system with closed-circuit of boom of hydraulic excavator. Mechanical Systems and Signal Processing, 2017, 82: 178–192

Wang T, Wang Q. An energy-saving pressure-compensated hydraulic system with electrical approach. IEEE/ASME Transactions on Mechatronics, 2014, 19(2): 570–578

Marani P, Ansaloni G, Leati E, et al. Active regeneration load sensing: A simulated comparison with traditional load sensing system in excavator working cycle. In: Proceedings of the 6th International Fluid Power Conference. Aachen, 2010

Jacobson E E. US Patent, 20150063968, 2015–05-03

Xu B, Ding R, Zhang J, et al. Modeling and dynamic characteristics analysis on a three-stage fast-response and largeflow directional valve. Energy Conversion and Management, 2014, 79(79): 187–199

Šimic M, Herakovič N. High-response hydraulic linear drive with integrated motion sensor and digital valve control. In: Proceedings of the 14th Scandinavian International Conference on Fluid Power. Tampere, 2015

Huova M. Energy efficient digital hydraulic valve control. Dissertation for the Doctoral Degree. Tampere: Tampere University of Technology, 2015

Manring N D, Mehta V S. Physical limitations for the bandwidth frequency of a pressure controlled, axial-piston pump. Journal of Dynamic Systems, Measurement, and Control, 2011, 133(6): 061005

Grabbel J, Ivantysynova M. An investigation of swash plate control concepts for displacement controlled actuators. International Journal of Fluid Power, 2005, 6(2): 19–36

Finzel R, Helduser S. New electro-hydraulic control systems for mobile machinery. In: Proceedings of Bath/ASME Symposium on Fluid power and Motion Control. Bath, 2008, 309–321

Hansen A H, Pedersen H C, Andersen T O, et al. Investigation of energy saving separate meter-in separate meter-out control strategies. In: Proceedings of the 12th Scandinavian International Conference on Fluid Power. Tampere, 2011

Sitte A, Weber J. Structural design of independent metering control systems. In: Proceedings of the 13th Scandinavian International Conference on Fluid Power. Linköping, 2013, 261–270

Axin M, Palmberg J, Krus P. Optimized damping in cylinder drives using the meter-out orifice: Design and experimental verification. In: Proceedings of the 8th International Fluid Power Conference. Dresden, 2012

Axin M, Krus P. Design rules for high damping in mobile hydraulic systems. In: Proceedings of the 13th Scandinavian International Conference on Fluid Power. Linköping, 2013

Rahmfeld R, Ivantysynova M. An overview about active oscillation damping of mobile machine structure. International Journal of Fluid Power, 2004, 5(2): 5–24

Pedersen H C, Andersen T O. Pressure feedback in fluid power systems-active damping explained and exemplified. IEEE Transactions on Control Systems Technology, 2017, PP (99): 1–12

Deboer C C, Yao B. Velocity control of hydraulic cylinder with only pressure feedback. In: Proceedings of the ASME International Mechanical Engineering Congress and Exposition. New York: ASME, 2001

Zaev E, Rath G, Kargl H, et al. Energy efficient active vibration damping. In: Proceedings of the 13th Scandinavian International Conference on Fluid Power. Linköping, 2013

Williamson C, Lee S, Ivantysynova M. Active vibration damping for an off-road vehicle with displacement controlled actuators. International Journal of Fluid Power, 2009, 10(3): 5–16

Kjelland M B, Hansen M R. Using input shaping and pressure feedback to suppress oscillations in slewing motion of lightweight flexible hydraulic crane. International Journal of Fluid Power, 2015, 16(3): 141–148

Fodor S, Vázquez C, Freidovich L, et al. Towards oscillation reduction in forestry cranes. In: Proceedings of the BATH/ASME 2016 Symposium on Fluid Power and Motion Control. 2016, V001T01A049

Kalmari J, Backman J, Visala A. Nonlinear model predictive control of hydraulic forestry crane with automatic sway damping. Computers and Electronics in Agriculture, 2014, 109(109): 36–45

Cristofori D, Vacca A, Ariyur K. A novel pressure-feedback based adaptive control method to damp instabilities in hydraulic machines. SAE International Journal Commercial Vehicle, 2012, 5(2): 586–596

Ding R, Xu B, Zhang J, et al. Self-tuning pressure-feedback control by pole placement for vibration reduction of excavator with independent metering fluid power system. Mechanical Systems and Signal Processing, 2017, 92: 86–106

Cheng M, Xu B, Zhang J, et al. Pump-based compensation for dynamic improvement of the electrohydraulic flow matching system. IEEE Transactions on Industrial Electronics, 2017, 64(4): 2903–2913

Jin K, Park T, Lee H. A control method to suppress the swing vibration of a hybrid excavator using sliding mode approach. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2012, 226(5): 1237–1253

Hu Q, Yang C, Liu S, et al. Torsional vibration active control of hybrid construction machinery complex shafting. Journal of Central South University, 2014, 21(9): 3498–3503

Wang T, Wang Q, Lin T. Improvement of boom control performance for hybrid hydraulic excavator with potential energy recovery. Automation in Construction, 2013, 30: 161–169

Ding R, Xu B, Zhang J, et al. Bumpless mode switch of independent metering fluid power system for mobile machinery. Automation in Construction, 2016, 68: 52–64

Lin H, Antsaklis P J. Stability and stabilizability of switched linear systems: A survey of recent results. IEEE Transactions on Automatic Control, 2009, 54(2): 308–322

Shenouda A, Book W. Optimal mode switching for a hydraulic actuator controlled with four-valve independent metering configuration. International Journal of Fluid Power, 2008, 9(1): 35–43

Xu B, Cheng M, Yang H, et al. A hybrid displacement/pressure control scheme for an electrohydraulic flow matching system. IEEE/ASME Transactions on Mechatronics, 2015, 20(6): 2771–2782

Kemmetmüller W, Fuchshumer F, Kugi A. Nonlinear pressure control of self-supplied variable displacement axial piston pumps. Control Engineering Practice, 2010, 18(1): 84–93

Heybroek K, Larsson J, Palmberg J O. Mode switching and energy recuperation in open-circuit pump control. In: Proceedings of the 10th Scandinavian International Conference on Fluid Power. Tampere, 2007

Kolks G, Weber J. Modiciency-efficient industrial hydraulic drives through independent metering using optimal operating modes. In: Proceedings of the 10th International Conference on Fluid Power. Dresden, 2016

Busquets E, Ivantysynova M. Toward supervisory-level control for the energy consumption and performance optimization of displacement-controlled hydraulic hybrid machines. In: Proceedings of the 10th International Conference on Fluid Power. Dresden, 2016

Yoon J, Manurung A. Development of an intuitive user interface for a hydraulic backhoe. Automation in Construction, 2010, 19(6): 779–790

Hansson A, Servin M. Semi-autonomous shared control of largescale manipulator arms. Control Engineering Practice, 2010, 18(9): 1069–1076

Araya H, Kagoshima M. Semi-automatic control system for hydraulic shovel. Automation in Construction, 2001, 10(4): 477–486

Frankel J G. Development of a haptic backhoe testbed. Thesis for the Master’s Degree. Atlanta: Georgia Institute of Technology, 2004

Karpenko M, Sepehri N, Anderson J. Decentralized coordinated motion control of two hydraulic actuators handling a common object. Journal of Dynamic Systems, Measurement, and Control, 2007, 129(5): 729–741

Kim WS, Tendick F, Ellis S R, et al. A comparison of position and rate control for telemanipulations with consideration of manipulator system dynamics. IEEE Journal on Robotics and Automation, 1987, 3(5): 426–436

Hayn H, Schwarzmann D. A haptically enhanced operational concept for a hydraulic excavator. In: Zadeh M H, ed. Advances in Haptics. InTech, 2010

Heikkinen J E. Virtual technology and haptic interface solutions for design and control of mobile working machines. Dissertation for the Doctoral Degree. Lappeenranta: Lappeenranta University of Technology, 2013

Available online: https://www.vrlab.ctw.utwente.nl/eq/PhantomOmni.html

Zarei-Nia K, Goharrizi A Y, Sepehri N, et al. Experimental evaluation of bilateral control schemes applied to hydraulic actuators: A comparative study. Transactions of the Canadian Society for Mechanical Engineering, 2009, 33(3): 377–398

Elton M D, Book W J. Comparison of human-machine interfaces designed for novices teleoperating multi-DOF hydraulic manipulators. In: Proceedings of the 20th IEEE International Symposium on Robot and Human Interactive Communications. Atlanta, 2011

Osafo-Yeboah B, Jiang S, Delpish R, et al. Empirical study to investigate the range of force feedback necessary for best operator performance in a haptic controlled excavator interface. International Journal of Industrial Ergonomics, 2013, 43(3): 197–202

Chung J, Lee S H, Yi B J, et al. Implementation of a foldable 3-DOF master device to a glass window panel fitting task. Automation in Construction, 2010, 19(7): 855–866

Lawrence P D, Salcudean S E, Sepehri N, et al. Coordinated and force-feedback control of hydraulic excavators. Experimental Robotics IV, 1997, 223: 181–194

Kim D, Kim J, Lee K, et al. Excavator tele-operation system using a human arm. Automation in Construction, 2009, 18(2): 173–182

Huang L, Kawamura T, Yamada H. Operability of a control method for grasping soft objects in a construction teleoperation robot tested in virtual reality. International Journal of Fluid Power, 2012, 13(3): 39–48

Enes A R. Shared control of hydraulic manipulators to decrease cycle time. Dissertation for the Doctoral Degree. Atlanta: Georgia Institute of Technology, 2010

Heikkinen J E, Handroos H M, Nishiumi T. Novel haptic controller for non-load mobile machine teleoperation. In: Proceedings of the 14th Scandinavian International Conference on Fluid Power. Tampere, 2015

Kim D, Oh K W, Lee C S, et al. Novel design of haptic devices for bilateral teleoperated excavators using the wave-variable method. International Journal of Precision Engineering and Manufacturing, 2013, 14(2): 223–230

Humphreys H C, Book W J, Feigh K M. Development of controller-based compensation for biodynamic feedthrough in a backhoe. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2014, 228(2): 107–120

Humphreys H C, Book W J, Huggins J D. Compensation for biodynamic feedthrough in backhoe operation by cab vibration control. In: Proceedings of the IEEE International Conference on Robotics and Automation. IEEE, 2011, 4284–4290

Elton MD. An efficient haptic interface for a variable displacement pump controller excavator. Thesis for the Master’s Degree. Atlanta: Georgia Institute of Technology, 2009

Elton M D. Matching feedback with operator intent for effective human-machine interfaces. Dissertation for the Doctoral Degree. Atlanta: Georgia Institute of Technology, 2012

Brandstetter R, Deubel T, Scheidl R, et al. Digital hydraulics and “Industrie 4.0”. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems & Control Engineering, 2016

Wang T, Zhou Z. A compact hydrostatic-driven electric generator: Design, prototype, and experiment. IEEE/ASME Transactions on Mechatronics, 2016, 21(3): 1612–1619

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51375431 and U1509204) and the Open Foundation of the State Key Laboratory of Fluid Power and Mechatronic Systems (Grant No. GZKF-201503).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, B., Cheng, M. Motion control of multi-actuator hydraulic systems for mobile machineries: Recent advancements and future trends. Front. Mech. Eng. 13, 151–166 (2018). https://doi.org/10.1007/s11465-018-0470-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-018-0470-5