Abstract

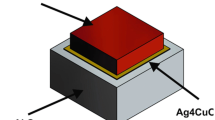

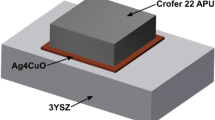

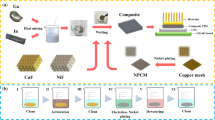

Applications like solid oxide fuel cells and sensors increasingly demand the possibility to braze ceramics to metals with a good resistance to high temperatures and oxidative atmospheres. Commonly used silver based active filler metals cannot fulfill these requirements, if application temperatures higher than 600°C occur. Au and Pd based active fillers are too expensive for many fields of use. As one possible solution nickel based active fillers were developed. Due to the high brazing temperatures and the low ductility of nickel based filler metals, the modification of standard nickel based filler metals were necessary to meet the requirements of above mentioned applications. To reduce thermally induced stresses wide brazing gaps and the addition of Al2O3 and WC particles to the filler metal were applied. In this study, the microstructure of the brazed joints and the thermo-chemical reactions between filler metal, active elements and WC particles were analyzed to understand the mechanism of the so called wide gap active brazing process. With regard to the behavior in typical application oxidation and thermal cycle tests were conducted as well as tensile tests.

Similar content being viewed by others

References

Mizuhara H. Brazing Alloy Containing Reactive Metals, Precious Metals, Boron and Nickel, US Patent 4447391, 1984

Sandin T A. Development of Active Nickel Based Brazing Filler Metals, Proceedings of the 3rd International Brazing and Soldering Conference, San Antonio, 2006, 367–372

Zuegner S. Nickelreaktivlot/Oxidkeramik- Fügungen als elektrisch isolierende Dichtungskonzepte für Hochtemperatur-Brennstoffzellen-Stacks, Forschungszentrum Jülich, 2009 (in German)

Wu X W, Chandel R S, Seow H P, Li H. Wide Gap Brazing of Stainless Steel to Nickel-based Superalloy. Journal of Materials Processing Technology, 2001, 113(1–3): 215–221

Zhang J, Zhang Z, Sun J, Liu X. Effect of Gap Filler and Clearance of Gap on Microstructure of Widegap Brazing Seam. ISIJ International, 2000, 40(7): 699–701

K. Bobzin, N. Bagcivan, N. Kopp, A. Schlegel, Die Entwicklung des Breitspaltaktivloetens als neue Fuegetechnologie fuer Keramik-Metall-Mischverbunde mit Einsatztemperaturen oberhalb 500°C, Keramische Zeitschrift, (5) 2011, 329–333 (in German)

Bobzin K, Schlaefer T, Kopp N, Schlegel A. Newly Developed Active Braze Powders Based on Commercial Nickel Brazes Using Zirconium as Active Element for Joining Ceramic to Metal. Materialwissenschaft und Werkstofftechnik, 2010, 41: 455–463

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bobzin, K., Zhao, L., Kopp, N. et al. Wide gap active brazing of ceramic-to-metal-joints for high temperature applications. Front. Mech. Eng. 9, 71–74 (2014). https://doi.org/10.1007/s11465-014-0291-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-014-0291-0