Abstract

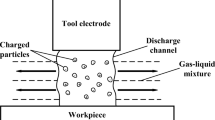

This paper presents the results of experimental studies carried out to conduct a comprehensive investigation on the influence of ultrasonic vibration of workpiece on the characteristics of Electrical Discharge Machining (EDM) process of FW4Welding Metal in comparison with the conventional EDM process. The studied process characteristics included the material removal rate (MRR), tool wear ratio (TWR), and surface roughness (R a and R max) of the workpiece after the EDM and ultrasonic assisted EDM (US-EDM) processes. The experiments performed under the designed full factorial procedure and the considered EDM input parameters included pulse on-time and pulse current. The experimental results show that in short pulse on-times, material removal rate in the USEDM process is approximately quadruple than that of the EDM process. On the contrary, in the long pulse on-times, ultrasonic vibration of workpiece leads to the reduction in the MRR. On the other hand, in short pulse on-times, the TWR in the US-EDM process is lower than that of in the EDM process, and this condition reverses with increase in the pulse on-time. Furthermore, the surface roughness of the workpiece machined by EDM process is slightly lower than that of applied to the US-EDM process.

Similar content being viewed by others

References

Ho K H, Newman S T. State of the art electrical discharge machining (EDM). International Journal of Machine Tools and Manufacture, 2003, 43(13): 1287–1300

Norliana Mohd A, Solomon D G, Fuad Bahari, Md. A review on current research trends in electrical discharge machining (EDM). International Journal of Machine Tools and Manufacture, 2007, 47(7–8): 1214–1228

I. T. FORGING Co., http://www.itforging.com/

Corewire Welding Technology, http://www.corewire.com/

Shabgard M R, Shotorbani R M. Mathematical modeling of machining parameters in electrical discharge machining of FW4 welded steel. World Academy of Science, Engineering and Technology, 2009, 52: 403–409

Shabgard M R, Sadizadeh B, Kakoulvand H. The effect of ultrasonic vibration of workpiece in electrical discharge machining of AISIH13 tool steel. World Academy of Science, Engineering and Technology, 2009, 52: 392–396

Kremer D, Lhiaubet C, Moisan A. A study of the effect of synchronizing ultrasonic vibrations with pulses in EDM. CIRP Annals-Manufacturing Technology, 1991, 40(1): 211–214

Thoe T B, Aspinwall D K, Killey N. Combined ultrasonic and electrical discharge machining of ceramic coated nickel steel. Journal of Materials Processing Technology, 1999, 92–93(1): 323–328

Lin Y C, Yan B H, Chang Y S. Machining characteristic of titanium alloy (Ti-6AI-4V) using a combination process of EDM with USM. Journal of Materials Processing Technology, 2000, 104(3): 171–177

Lin Y C, Yan B H, Huang F Y. Surface modification of AI-Zn-Mg aluminum alloy using the combined process of EDM with USM. Journal of Materials Processing Technology, 2001, 115(3): 359–366

Ghoreishi M, Atkinson J. A comparative experimental study of machining characteristics in vibratory, rotary and vibro-rotary electro discharge machining. Journal of Materials Processing Technology, 2002, 120(1–3): 374–384

Zhao W S, Wang Z L, Di S C, Chi G X, Wei H Y. Ultrasonic and electric discharge machining to deep and small hole on titanium alloy. Journal of Materials Processing Technology, 2002, 120(1–3): 101–106

Gao C S, Liu Z X. A study of ultrasonically aided micro-electricaldischarge machining by the application of workpiece vibration. Journal of Materials Processing Technology, 2003, 139(1–3): 226–228

Egashira K, Matsugasako A, Tsuchiya H, Miyazaki M. Electrical discharge machining with ultra low discharge energy. Precision Engineering, 2006, 30(4): 414–420

Chern G L, Wu Y J E, Liu S F. Development of a micro-punching machine and study on the influence of vibration machining in micro-EDM. Journal of Materials Processing Technology, 2006, 180(1–3): 102–109

Shabgard M R, Ivanov A, Rees A. Influence of EDM machining on surface integrity of WC-Co. Manufacturing Engineering Centre, Cardiff University, 2006

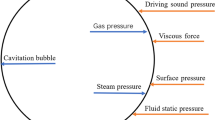

Shervani-Tabar M T, Abdullah A, Shabgard M R. Numerical study on the dynamics of an electrical discharge generated bubble in EDM. Engineering Analysis with Boundary Elements, 2006, 30(6): 503–514

Jones H M, Kunhardt E E. The Influence of pressure and conductivity on the pulsed breakdown of water. IEEE Transactions on Dielectrics and Electrical Insulation, 1994, 1(6): 1016–1025

Takeshi H, Minoru H, Toshiaki O. A Mechanical vibration assisted plasma etcher for etch rate improvement. Journal of the International Societies for Precision Engineering and Nanotechnology, 2002, 26: 137–141

Roth J R. Industrial Plasma Engineering Volume 2: Applications to Non-thermal Plasma Processing. Bristol: IOP Publishing Ltd., 2001

Elman C. Jameson, Electrical Discharge Machining. Society of Manufacturing Engineers, 2001

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shabgard, M., Kakolvand, H., Seyedzavvar, M. et al. Ultrasonic assisted EDM: Effect of the workpiece vibration in the machining characteristics of FW4 Welded Metal. Front. Mech. Eng. 6, 419–428 (2011). https://doi.org/10.1007/s11465-011-0246-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-011-0246-7