Abstract

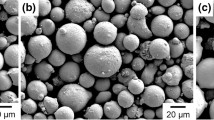

The aim of this paper was to address the rolling contact fatigue (RCF) failure mechanisms of plasmasprayed Cr3C2-NiCr coatings under different tribological conditions of contact stress. Weibull distribution plots of fatigue lives of the coated specimens at different contact stresses were obtained. The failure modes of coatings were identified on the basis of wore surface observations of the failed coatings. Results showed that the RCF failure modes can be classified into four main categories, i.e., surface abrasion, spalling, cohesive delamination, and interfacial delamination. The probabilities of the surface abrasion and spalling type failures were relatively high at low contact stress. When the coatings were subjected to abrasion and spalling type failures, the failure of the coating was depended on the microstrcture of the coating. The stress concentration near the micro-defects in the coating may be the may reason for the formation of spall. The coatings were prone to fail in delamination under higher contact stresses. However, the delamination of coating may be related to distribution of shear stress amplitude within coating. The location of maximum shear stress amplitude can be used as a key parameter to predict the initiation of subsurface cracks within coating in rolling contact.

Similar content being viewed by others

References

Nieminen R, Vuoristo P, Niemi K, Mäntylä T, Barbezat G. Rolling contact fatigue failure mechanisms in plasma and HVOF sprayed WC-Co coatings. Wear, 1997, 212(1): 66–77

Miller G R, Keer L M, Cheng H S. On the mechanics of fatigue crack growth due to contact loading. P Roy Soc Lond: Mat, 1813, 1985(397): 197–209

Rosado L, Jain V K, Trived H K. The effect of diamond-like carbon coatings on the rolling fatigue and wear of M50 steel. Wear, 1997, 212(1): 1–6

Ahmed R, Hadfield M. Rolling contact fatigue behaviour of thermally sprayed rolling elements. Surface and Coatings Technology, 1996, 82(1–2): 176–186

Stewart S, Ahmed R. Contact fatigue failure modes in hot isostatically pressed WC-12%Co coatings. Surface and Coatings Technology, 2003, 172(2–3): 204–216

Makela A, Vuroisto P, Lahdensuo M, Niemi K, Mantyla T. Rolling contact fatigue testing of thermally sprayed coatings. International Journal of Fatigue, 1995, 17: 305

Ahmed R. Contact fatigue failure modes of HVOF coatings. Wear, 2003, 253(3–4): 473–487

Nakajima A, Mawatari T, Yoshida M, Tani K, Nakahira A. Effects of coating thickness and slip ratio on durability of thermally sprayed WC cermet coating in rolling/sliding contact. Wear, 2000, 241(2): 166–173

Ahmed R, Hadfield M. Experimental measurement of the residual stress field within thermally sprayed rolling elements. Wear, 1997, 209(1–2): 84–95

Ahmed R, Hadfield M. Wear of high-velocity oxy-fuel (HVOF)-coated cones in rolling contact. Wear, 1997, 203–204: 98–106

Nuruzzaman D M, Nakajima A, Mawatari T. Effects of substrate surface finish and substrate material on durability of thermally sprayed WC cermet coating in rolling with sliding contact. Tribology International, 2006, 39(7): 678–685

Ahmed R, Hadfield M. Failure modes of plasma sprayed WC-15%Co coated rolling elements. Wear, 1999, 230(1): 39–55

Shen X Y, Yu S Y. Performance in resistance to surface fatigue for Cr3C2-25%NiCr coatings by plasma spray and CDS spray. Tribology Letters, 2004, 16(3): 173–180

Ahmed R, Hadfield M. Rolling contact fatigue performance of plasma sprayed coatings. Wear, 1998, 220(1): 80–91

Sarma B Y, Mayuram M M. Some studies on life prediction of thermal sprayed coatings under rolling contact conditions. ASME J Tribol, 2000, 122(3): 503–510

Ahmed R, Hadfield M. Rolling contact fatigue performance of detonation gun coated elements. Tribology International, 1997, 30(2): 129–137

Tobe S, Kodama S, Misawa H. Rolling contact behaviour of plasma sprayed coating on aluminiumalloy. In: Proc Nat Thermal Spray Conf. Tokyo, Japan, ASM international, Anaheim, CA, 1990: 171–178

Berger L M, Vuoristo P, Mantyla T, Gruner W. Study of oxidation behavior of WC-Co, Cr3C2-NiCr and Tic-Ni-based materials in thermal spray processes. In: Coddet C, eds. Proceedings of the 15th International Thermal Spray Conference. Nice, France, 1998: 75–82

Hertz H. Überdie Berührung fester elastischer Körper. J Reine Angew Math, 1881, 92: 156–171

Johnson K L. Contact Mechanics. Cambridge: Cambridge University Press, 1992

Shimizu S. P-S-N/P-F-L curve approach using three-parameter Weibull distribution for life and fatigue analysis of structural and rolling contact components. Tribol Trans, 2005, 48(4): 576–582

Robert B A, Breneman J E, Medlin C H, Reinman G L. Weibull analysis handbook, US Air Force AFWAL-TR-83-2079, prepared for the Aero Propulsion and Power Laboratory, Wright-Patterson AFB, Ohio, 1983

Kuroda S, Clyne T W. Quenching stress in thermally sprayed coatings. Thin Solid Films, 1991, 200(1): 49–66

Kato K, Hokkirigawa K. Abrasive wear diagram. In: Proceedings of the Eurotrib’85. Amsterdam: Elsevier, 1985: 9–12

Holmberg K, Matthews A, Ronkainen H. Coatings tribologycontact mechanisms and surface design. Tribology International, 1998, 31(1–3): 107–120

Tallian T. Failure Atlas for Hertz Contact Machine Elements. New York: ASME Press, 1992

Stewart S, Ahmed R, Itsukaichi T. Rolling contact fatigue of post-treated WC-NiCrBSi thermal spray coatings. Surface and Coatings Technology, 2005, 190(2–3): 171–189

Liang G Y, Su J Y. The microstructure and tribological characteristics of laser-clad Ni-Cr-Al coatings on aluminium alloy. Materials Science and Engineering, 2000, A290: 207–212

Miyashita Y, Yoshimura Y, Xu J Q, Horikoshi M, Mutoh Y. Subsurface crack propagation in rolling contact fatigue of sintered alloy. JSME International Journal, 2003, 46(3): 341–347

Lundberg G, Palmgren A. Dynamic capacity of rolling bearings. Acta Polytechnica-Mech. Eng Series, 1947, 1: 4–51

Fellows L, Nowell D, Hills D. On the initiation of fretting fatigue cracks. Wear, 1997, 205(1–2): 120–129

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Xuan, F., Tu, S. et al. Durability of plasma-sprayed Cr3C2-NiCr coatings under rolling contact conditions. Front. Mech. Eng. 6, 118–135 (2011). https://doi.org/10.1007/s11465-011-0127-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-011-0127-0