Abstract

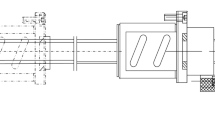

Empirical model of machine tools on thermal error has been widely researched, which can compensate for thermal error to some extent but not suitable for thermal dynamic errors produced by dynamic heat sources. The thermoelastic phenomenon of unidimensional heat transfer of ballscrews influenced by changeable heat sources is analyzed based on the theory of heat transfer. Two methods for system identification (the least square system identification and BP artificial neural network (ANN) system identification) are put forward to establish a dynamic characteristic model of thermal deformation of ballscrews. The model of thermal error of the X axis in a feed system of DM4600 vertical miller is established with a fine identification effect. Comparing the results of the two identification methods, the BP ANN system identification is more precise than the least square system identification.

Similar content being viewed by others

References

Huang Shyh-chour. Analysis of a model to forecast thermal deformation of ball screw feed drive systems. International Journal of Machine Tools & Manufacture, 1994, 35: 1099–1104

Kim S K, Cho D W. Real time estimation of temperature distribution in a ball-screw system. International Journal of Ma-chine Tools and Manufacture, 1997, 37(4): 451–464

Wu Cheng-Hsien, Kung Yu-Tai. Thermal analysis for the feed drive system of a CNC machine center. International Journal of Machine Tools & Manufacture, 2003, 43: 1521–1528

Song Xianchun, Wang Zhaotan, Liu Xianyin. The thermal deformation control during precision ball screw grinding. Manufacturing Technology & Machine Tool, 2006, (1): 59–61

Yang Hong, Ni Jun. Adaptive model estimation of machinetool thermal errors based on recursive dynamic modeling strategy. International Journal of Machine Tools & Manufacture, 2005, 45: 1–11

Xia Junyong, Hu Youmin, Wu Bo, Shi Tielin. Numerical solution and simulation of the thermal dynamic characteristics of ball-screws. Frontiers of Mechanical Engineering in China, 2008, 3(1): 28–36

Xia Junyong, Hu Youmin, Wu Bo, Shi Tielin. The thermal dynamic characteristic of ball-screw when taking in thermal elasticity. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2008, 36(3): 1–4

Yang Hong, Ni Jun. Dynamic modeling for machine tool thermal error compensation. ASME Trans. Journal of Manufacturing Science and Engineering, 2003, 125: 245–254

Yu Changmin. Heat Transfer and Numerical Analysis. Beijing: Press of Tshinghua University, 1982

Yu Zuopin, Lu Lu. Heat Transfering. Beijing: High Education Press, 1995: 14–31

Lennart Ljung. System Identification-theory for User. Prentice Hall PTR, 1999

Hou Yuanbing, Wang Meietal. System identificating and Matlab simulating. Beijing: Scientific Press, 2004: 53–55

Wang Yongji. Neural Network Controling. Beijing: Mechanical Industry Press, 1998

Lo Chih-hao, Yuan Jingxia, Ni Jun. Optimal temperature variable selection by grouping approach for thermal error modeling and compensation. International Journal of Machine Tools & Manufacture, 1999, 39: 1383–1396

Yang Jianguo, Yuan Jingxia, Ni Jun. Thermal error mode analysis and robust modeling for error compensation on a CNC turning center. International Journal of Machine Tools & Manufacture, 1999, 39: 1367–1381

Lee D S, Choi J Y, Choi D H. ICA based thermal source extraction and thermal distortion compensation method for a machine tool. International Journal of Machine Tools & Manufacture, 2003, 43: 589–597

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, J., Hu, Y., Wu, B. et al. Theory analysis and system identification methods on thermal dynamics characteristics of ballscrews. Front. Mech. Eng. China 3, 408–415 (2008). https://doi.org/10.1007/s11465-008-0061-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-008-0061-y