Abstract

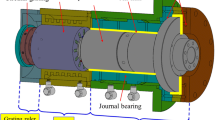

Air-bearings are installed between the stator and the mover of ultra-precision linear stages to suppress vibration and mechanical contact. Spring-damping elements are used to emulate the complex interaction of the finite element model (FEM) developed in this paper and the system dynamic behaviors are analyzed. Through the experimental modal test, the validity and reliability of the model are proven. However, the dynamic characteristics including mode frequency, mode shape, and response amplitude are obviously changed with the position of air-bearings. The combined optimization method is used to optimize the air-bearings position. The best and worst positions are obtained using the dynamic characteristic analysis. The method can be generalized to the connection position of different components in manufacture elements and to implement the system dynamic characteristics optimization when the connection position can be changed.

Similar content being viewed by others

References

Dal H I, Kim C E. Finite element force calculation of a linear induction motor taking account of the movement. IEEE Transactions on Magnetic, 1994, 30(5): 3495–3498

Kim J K, Joo S W, Hahn S C. Static characteristics of linear BLDC motor using equivalent circuit and finite element method. IEEE Transactions on Magnetic, 2004, 40(2): 742–745

Jang S M, Choi J Y, Cho H W. Dynamic characteristic analysis and experiments of moving-magnet linear actuator with cylindrical Halbach array. IEEE Transactions on Magnetic, 2005, 41(10): 3814–3816

Lu Changan, Tony R, Eastham. Transient and dynamics performance of a linear induction motor. Industry Application Society Annual Meeting, 1993, 1: 266–273

Stout K J, Barrans S M. The design of aerostatic bearings for application to nanometer resolution manufacturing machine systems. Tribology International, 2000, 33(12): 803–809

Mekid S. High precision linear side. Part I: design and construction. International Journal of Machine Tool & Manufacture, 2000, 40(7): 1039–1050

Mekid S, Olejniczak O. High precision linear side. Part II: control and measurement. International Journal of Machine Tool & Manufacture, 2000, 40(7): 1051–1064

Liu C T, Hsu S C. Analysis of linear electromagnetic motion devices by multiple-reference frame theory. IEEE Transactions on Magnetic, 1998, 34(4): 2063–1341

Dejima S, Gao Wei, Shimizu H, Kiyono S, Tomita Y. Precision positioning of a five degree-of-freedom planar motion stage. Mechatronics, 2005, 15(8): 969–987

Chen X D, He X M. The effect of the recess shape on performance analysis of the gas-lubricated bearing in optical lithography. Tribology International, 2006, (39): 1336–1341

Khatait J P, Lin W, Lin W. J. Design and development of orifice-type aerostatic thrust bearing. SIMTech technical reports, 2005, 6(1): 7–12

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, X., Li, Z. Air-bearing position optimization based on dynamic characteristics of ultra-precision linear stages. Front. Mech. Eng. China 3, 400–407 (2008). https://doi.org/10.1007/s11465-008-0060-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-008-0060-z