Abstract

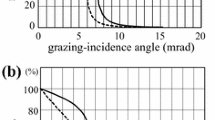

A non-coaxial grazing X-ray microscope, consisting of four spherical mirrors, is designed for diagnosis of inertial confinement fusion (ICF). The aberrations and imaging quality of the microscope are analyzed. To acquire excellent imaging quality, suitable tolerances for manufacturing and assembling the microscope are necessary. This paper researches the changes of Gauss parameters and aberrations due to component and subsystem parameters (such as the radius of the mirror, angle between mirrors, grazing angle, object distance, etc.). Here, spot diagrams and modulation transfer function (MTF) are first adopted to quantitatively evaluate the imaging quality of the microscope. Suitable manufacturing tolerances of components and assembly tolerances of the system are established on the basis of the discussion and analysis. A set of non-coaxial grazing X-ray microscopes is manufactured based on the tolerances. In site tests of ICF, the images with high resolution are obtained by the microscope.

Similar content being viewed by others

References

Wolter H. Mirror systems with glancing incidence as image-producing optics for X-rays. Ann Phys, 1952, 10: 94–114

Kirkpatrick P, Baez A V. Formation of optical images by X-rays. Opt Soc Am, 1948, 38: 776–774

Wang Zhanshan. Effect of film thickness errors on performance of soft X-ray multilayer. Optics and Precision Engineering, 2003, 11(2): 136–138 (in Chinese)

Zhang Z, Wang Z S, Wu W J, et al. Research on multilayer films used in synchrotron radiation monochromator. Optics and Precision Engineering, 2003, 11(1): 49–54 (in Chinese)

Hu Jiasheng, Zhao Lingling, Li Xiang. Design and analysis of X-ray microscope of four mirrors working at grazing incidence. Journal of Optoelectronics Laser, 2005, 16(5): 534–537 (in Chinese)

Hu Jiasheng, Zhao Lingling, Li Xiang, et al. Imaging quality analysis of KBA X-ray microscope working at grazing incidence. SPIE, 2004, 5638: 956–960

Hu Jiasheng, Wu Xu. Manufacturing and testing of X-ray imaging components with high precision. Optics and Precision Engineering, 2005, 13(5): 620–625

Sauneuf R, Dalmasso J M, Jalinaud T, et al. Large-field high-resolution X-ray microscope for studying laser plasmas, Rev Sci Instrum, 1995, 68(9): 3412–3420

Hu Jiasheng, Song Limin. Roughness effects on the reflectance in the design of a soft X-ray multi-layler mirror. Optical and Precision Engineering, 2004, 12(4): 380–385 (in Chinese)

Hu Jiasheng. Introduction to Optical Engineering. 2nd ed. Dalian: Dalian University of Technology Press, 2005, 829–864 (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

__________

Translated from Optics and Precision Engineering, 2006, 14(1): 34–42 [译自: 光学精密工程]

Rights and permissions

About this article

Cite this article

Zhao, L., Hu, J. & Li, X. Error analysis of the parameters for non-coaxial grazing X-ray microscope. Front. Mech. Eng. China 2, 323–329 (2007). https://doi.org/10.1007/s11465-007-0057-z

Issue Date:

DOI: https://doi.org/10.1007/s11465-007-0057-z