Abstract

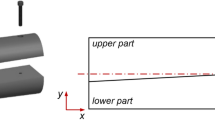

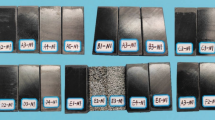

Drop hammer tests were carried out to study the axial crash behavior of aluminum foam-filled hat sections. First, the axial crash tests of the empty hat sections, aluminum foam and the aluminum foam-filled hat sections were carried out; then, based upon the test results, the axial crash behavior of the aluminum foam-filled hat sections were analyzed. It was found that aluminum foam filling can increase the energy absorption capacities of the hat sections. Compared with the non-filled structures, aluminum foam-filled structures were much more stable and needed less mass to absorb the specified energy.

Similar content being viewed by others

References

White M D, Jones N, Experimental study into the energy absorbing characteristics of top-hat and double-hat thin-walled sections subjected to dynamic axial crushing, Proceedings of the Institution of Mechanical Engineering, Part D, Journal of Automobile Engineering, 1999, 213(D4): 259–278

White M D, Jones N, A theoretical analysis for the dynamic axial crushing of top hat and double-hat thin-walled sections, Proceedings of the Institution of Mechanical Engineering, Part D, Journal of Automobile Engineering, 1999, 213(D4): 307–325

Wong H F, Rhodes J, Zaras J, et al, Experimental investigation of static progressive crushing of closed-hat section members, Gupta N K ed, Plasticity and impact mechanics, New Delhi, 1997, New Age International Ltd, 1997: 250–272

Zhu Xichan, Test and research for collision characteristic of automobile body structure, Automobile Technology, 1999, 4: 20–24

Hanssen A G, Langeseth M, Hopperstad O S, Static and dynamic crushing of circular aluminum extrusions with aluminum foam filler, International Journal of Impact Engineering 2000, 24(5):475–507

Hanssen A G, Langeseth M, Hopperstad O S, Static and dynamic crushing of square aluminum extrusions with aluminum foam filler, International Journal of Impact Engineering 2000, 24(4):347–383

Wang Qingchun, Fan Zijie, Song Hongwei, et al, Experimental studies on the axial crushing behaviors of aluminum foam-filled hat sections, Chinese Journal of Mechanical Engineering, 2004, 40(11):98–102. (in Chinese)

Mao Zhu, Gui Lingjin, Fan Zijie, The develop and desige of drop hammer crash system, Technology and Management of Experiment, 2003, 20(5):22–29

Author information

Authors and Affiliations

Corresponding author

Additional information

__________

Translated from Chinese Journal of Mechanical Engineering, 2006, 42(4) (in Chinese)

Rights and permissions

About this article

Cite this article

Wang, Qc., Fan, Zj., Gui, Lj. et al. Experimental studies on the axial crash behavior of aluminum foam-filled hat sections. Front. Mech. Eng. China 1, 381–387 (2006). https://doi.org/10.1007/s11465-006-0044-9

Issue Date:

DOI: https://doi.org/10.1007/s11465-006-0044-9