Abstract

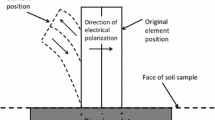

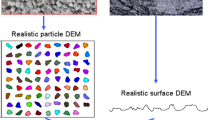

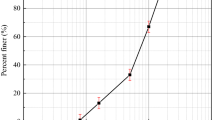

This paper presents a versatile interface direct shear test apparatus developed for systematically investigating the shear behaviour of geotechnical interfaces. The apparatus can support the testing of several particle–continuum as well as continuum–continuum interfaces and can also accommodate different configurations of testing, viz. conventional and fixed-box interface shear testing, by a simple rearrangement of the different components. The apparatus facilitates the visualisation and measurement of the deformation of geotextiles under pull-out loading, particle kinematics and the acoustic behaviour of soil–continuum interfaces by accommodating advanced deformation-measurement devices like digital cameras for digital image correlation (DIC) and sensors for acoustic emission (AE). The paper describes the design of all the components of the apparatus and the results of the interface shear tests of different particle–continuum and continuum–continuum interfaces. The repeatability of the test results is verified through multiple tests on the same interface. Results of the interface shear tests indicating the sensitivity of the apparatus for the different modes of testing are also presented. The provisions such as the shear box with a transparent side wall, the moving platform with an interchangeable transparent bottom and the capability to accommodate AE studies facilitated a detailed understanding of various types of interfaces. The DIC results provided insights into the shear zone formation at the dilative interfaces and the deformation of a geotextile under a pull-out load. The AE studies provided a new perspective on the response of particle–continuum interfaces.

Similar content being viewed by others

Data availability

The datasets generated and analysed during the current study are available from the corresponding author upon reasonable request.

References

Abu Qamar MI, Suleiman MT (2023) Development of cyclic interface shear test device and testing procedure to measure the response of cohesive soil-structure interface. Geotech Test J 46:20210270. https://doi.org/10.1520/gtj20210270

Aiban SA, Ali SM (2001) Nonwoven geotextile-sabkha and -sand interface friction characteristics using pull-out tests. Geosynth Int 8:193–220. https://doi.org/10.1680/gein.8.0192

Airey DW, Kelly RB (2010) Interface behaviours from large diameter ring shear tests. In: Frost JD (ed) Proceedings of the research symposium on characterization and behavior of interfaces. IOS Press, Amsterdam, Netherlands, pp 1–6

Alawneh AS, Husein Malkawi AI, Al-Deeky H (1999) Tension tests on smooth and rough model piles in dry sand. Can Geotech J 36:746–753. https://doi.org/10.1139/t98-104

Anubhav BPK (2010) Modeling of soil-woven geotextile interface behavior from direct shear test results. Geotext Geomembr 28:403–408. https://doi.org/10.1016/j.geotexmem.2009.12.005

Arulrajah A, Rahman MA, Piratheepan J, Bo MW, Imteaz MA (2014) Evaluation of interface shear strength properties of geogrid-reinforced construction and demolition materials using a modified large-scale direct shear testing apparatus. J Mater Civ Eng 26:974–982. https://doi.org/10.1061/(asce)mt.1943-5533.0000897

ASTM D698–12 (2021) Standard test methods for laboratory compaction characteristics of soil using standard effort (12, 400 ft-lbf/ft 3 (600 kN-m/m3)). ASTM Int 3:1–11. https://doi.org/10.1520/D0698-12R21

ASTM D854 (2000) Standard test methods for specific gravity of soil solids by water pycnometer. ASTM Int 2458000:1–7. https://doi.org/10.1520/D0854-14

ASTM D2487–17 (2017) Standard practice for classification of soils for engineering purposes (unified soil classification system). ASTM Int. https://doi.org/10.1520/D2487-17

ASTM D3080 (2011) Standard test method for direct shear test of soils under consolidated drained conditions. ASTM Int. https://doi.org/10.1520/D3080-04

ASTM D4253–16 (2016) Standard test methods for maximum index density and unit weight of soils using a vibratory table. ASTM Int 00:1–15. https://doi.org/10.1520/D4253-16E01.1.3

ASTM D4254–16 (2016) Standard test methods for minimum index density and unit weight of soils and calculation of relative density. ASTM Int I:9. https://doi.org/10.1520/D4254-16.2

ASTM D4318–17 (2005) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM Int 04:1–14. https://doi.org/10.1520/D4318-17

ASTM D5321 (2021) Standard test method for determining the shear strength of soil-geosynthetic and geosynthetic-geosynthetic interfaces by direct shear. ASTM Int. https://doi.org/10.1520/D5321

ASTM D5321, D5321M-21 (2021) Standard test method for determining the shear strength of soil-geosynthetic and geosynthetic-geosynthetic interfaces by direct shear. ASTM Int. https://doi.org/10.1520/D5321_D5321M-21

ASTM E4 (2021) Standard practices for force calibration and verification of testing machines. ASTM Int. https://doi.org/10.1520/E0004-21

ASTM E2309, E2309M (2020) Standard practices for verification of displacement measuring systems and devices used in material testing machines. ASTM Int. https://doi.org/10.1520/E2309_E2309M-20

Blaber J, Adair B, Antoniou A (2015) Ncorr: open-source 2D digital image correlation matlab software. Exp Mech 55:1105–1122. https://doi.org/10.1007/s11340-015-0009-1

Byrne RJ, Kendall J, Brown S (1992) Cause and mechanism of failure Kettleman Hills landfill B-19, phase IA. In: Stability and performance of slopes and embankments II. ASCE, pp 1188–1215

Choo CS, Ong DEL (2015) Evaluation of pipe-jacking forces based on direct shear testing of reconstituted tunneling rock spoils. J Geotech Geoenviron Eng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001348

Chu L-M, Yin J-H (2005) Comparison of interface shear strength of soil nails measured by both direct shear box tests and pullout tests. J Geotech Geoenviron Eng 131:1097–1107. https://doi.org/10.1061/(asce)1090-0241(2005)131:9(1097)

Dixon N, Jones DRV, Fowmes GJ (2006) Interface shear strength variability and its use in reliability-based landfill stability analysis. Geosynth Int 13:1–14. https://doi.org/10.1680/gein.2006.13.1.1

Dove JE, Frost JD (1996) A method for measuring geomembrane surface roughness. Geosynth Int 3:369–392. https://doi.org/10.1680/gein.3.0067

Dove JE, Frost JD (1999) Peak friction behavior of smooth geomembrane-particle interfaces. J Geotech Geoenviron Eng 125:544–555. https://doi.org/10.1061/(ASCE)1090-0241(1999)125:7(544)

Dove JE, Jarrett JB (2002) Behavior of dilative sand interfaces in a geotribology framework. J Geotech Geoenviron Eng 128:25–37. https://doi.org/10.1061/(ASCE)1090-0241(2002)128:1(25)

Drescher A, Vardoulakis I (1982) Geometric softening in triaxial tests on granular material. Geotechnique 32:291–303. https://doi.org/10.1680/geot.1982.32.4.291

Dyer MR (1985) Observation of the stress distribution in crushed glass with applications to soil reinforcement. University of Oxford, Oxford

Esterhuizen JJB, Filz GM, Duncan JM (2001) Constitutive behavior of geosynthetic interfaces. J Geotech Geoenviron Eng 127:834–840. https://doi.org/10.1061/(ASCE)1090-0241(2001)127:10(834)

Feng SJ, Shen Y, Zheng QT, Shi JL (2022) Multi-functional direct shear apparatus for geosynthetic interfaces with its application on various GMB/GCL interfaces. Acta Geotech 17:993–1008. https://doi.org/10.1007/s11440-021-01279-6

Fowmes GJ, Dixon N, Fu L, Zaharescu CA (2017) Rapid prototyping of geosynthetic interfaces: Investigation of peak strength using direct shear tests. Geotext Geomembr 45:674–687. https://doi.org/10.1016/j.geotexmem.2017.08.009

Frost JD, Kim D, Lee S (2012) Microscale geomembrane-granular material interactions. KSCE J Civ Eng 16:79–92. https://doi.org/10.1007/s12205-012-1476-x

Fuggle AR (2011) Geomaterial gradation influences on interface shear behavior. (Doctoral Dissertation), Georgia Institute of Technology, Atlanta, USA

Gayathri VL, Vangla P (2023) Experimental investigation of the suitability of 3D printing for soil-continuum interface studies. Geo-congress 2023. American Society of Civil Engineers, Reston, VA, pp 497–506

Gayathri VL, Vangla P (2023) Shear behaviour of snakeskin-inspired ribs and soil interfaces. Acta Geotech. https://doi.org/10.1007/s11440-023-02009-w

Gayathri VL, Vangla P, Riya A (2022) Effect of snakeskin-inspired patterns on the shear response of soil—continuum interfaces. Int J Geotech Eng 16:759–775. https://doi.org/10.1080/19386362.2022.2066049

Gilbert RB, Byrne RJ (1996) Strain-softening behavior of waste containment system interfaces. Geosynth Int 3:181–203. https://doi.org/10.1680/gein.3.0059

Hazel J, Stone M, Grace MS, Tsukruk VV (1999) Nanoscale design of snake skin for reptation locomotions via friction anisotropy. J Biomech 32:477–484. https://doi.org/10.1016/s0021-9290(99)00013-5

Hettler A, Vardoulakis I (1984) Behaviour of dry sand tested in a large triaxial apparatus. Geotechnique 34:183–197. https://doi.org/10.1680/geot.1984.34.2.183

Hryciw RD, Irsyam M (1993) Behavior of sand particles around rigid ribbed inclusions during shear. Jpn Soc Soil Mech Found Eng 33:1–13

Huang L, Martinez A (2020) Study of interface frictional anisotropy at bioinspired soil-structure interfaces with compliant asperities. Geo-congress 2020: biogeotechnics. American Society of Civil Engineers Reston, VA, pp 253–261

Indraratna B, Ngo NT, Rujikiatkamjorn C, Vinod JS (2014) Behavior of fresh and fouled railway ballast subjected to direct shear testing: discrete element simulation. Int J Geomech 14:34–44. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000264

Irsyam M, Hryciw RD (1991) Friction and passive resistance in soil reinforced by plane ribbed inclusions. Geotechnique 41:485–498. https://doi.org/10.1680/geot.1991.41.4.485

Jewell RA (1989) Direct shear tests on sand. Géotechnique 39:309–322. https://doi.org/10.1680/geot.1989.39.2.309

Jewell RA, Wroth CP (1987) Direct shear tests on reinforced sand. Géotechnique 37:53–68. https://doi.org/10.1680/geot.1987.37.1.53

Kandpal L, Vangla P (2023) New insights into geotribology of non-dilative interfaces from novel experimental studies. Geosynth Int. https://doi.org/10.1680/jgein.23.00013

Khan R, Latha GM (2023) Multi-scale understanding of sand-geosynthetic interface shear response through Micro-CT and shear band analysis. Geotext Geomembr 51:437–453. https://doi.org/10.1016/j.geotexmem.2023.01.006

Koerner RM (2005) Designing with geosynthetics. Fifth Pearson Education Inc, New Jersey

Lamb H (1917) On waves in an elastic plate. Proc Royal Soc London Ser A Contain Papers Math Phys Char 93:114–128. https://doi.org/10.1098/rspa.1917.0008

Lashkari A, Jamali V (2021) Global and local sand–geosynthetic interface behaviour. Geotechnique 71:346–367. https://doi.org/10.1680/jgeot.19.P.109

Lee KM, Manjunath VR (2000) Soil-geotextile interface friction by direct shear tests. Can Geotech J 37:238–252. https://doi.org/10.1139/t99-124

Lin W, Liu A, Mao W, Koseki J (2020) Acoustic emission behavior of granular soils with various ground conditions in drained triaxial compression tests. Soils Found 60:929–943. https://doi.org/10.1016/j.sandf.2020.06.002

Liu SH, Sun D, Matsuoka H (2005) On the interface friction in direct shear test. Comput Geotech 32:317–325. https://doi.org/10.1016/j.compgeo.2005.05.002

Lopes ML, Silvano R (2010) Soil/geotextile interface behaviour in direct shear and pullout movements. Geotech Geol Eng 28:791–804. https://doi.org/10.1007/s10706-010-9339-z

Maghool F, Arulrajah A, Mirzababaei M, Suksiripattanapong C, Horpibulsuk S (2020) Interface shear strength properties of geogrid-reinforced steel slags using a large-scale direct shear testing apparatus. Geotext Geomembr 48:625–633. https://doi.org/10.1016/j.geotexmem.2020.04.001

Martinez A, Dejong J, Akin I, Aleali A, Arson C, Atkinson J, Bandini P, Baser T, Borela R, Boulanger R, Burrall M, Chen Y, Collins C, Cortes D, Dai S, Dejong T, Del Dottore E, Dorgan K, Fragaszy R, Frost JD, Full R, Ghayoomi M, Goldman DI, Gravish N, Guzman IL, Hambleton J, Hawkes E, Helms M, Hu D, Huang L, Huang S, Hunt C, Irschick D, Lin HT, Lingwall B, Marr A, Mazzolai B, Mcinroe B, Murthy T et al (2021) Bio-inspired geotechnical engineering: principles, current work, opportunities and challenges. Géotechnique. https://doi.org/10.1680/jgeot.20.p.170

Martinez A, Frost JD (2017) The influence of surface roughness form on the strength of sand—structure interfaces. Geotech Lett 7:104–111. https://doi.org/10.1680/jgele.16.00169

Martinez A, Frost JD (2017) The influence of surface roughness form on the strength of sand–structure interfaces. Géotech Lett 7:104–111. https://doi.org/10.1680/jgele.16.00169

Martinez A, Palumbo S, Todd BD (2019) Bioinspiration for anisotropic load transfer at soil-structure interfaces. J Geotech Geoenviron Eng 145:04019074-1-04019074–14. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002138

Marvi H, Cook JP, Streator JL, Hu DL (2016) Snakes move their scales to increase friction. Biotribology 5:52–60. https://doi.org/10.1016/j.biotri.2015.11.001

Paikowsky S, Player C, Connors P (1995) A dual interface apparatus for testing unrestricted friction of soil along solid surfaces. Geotech Test J 18:168–193. https://doi.org/10.1520/GTJ10320J

Palmeira EM (1987) The study of soil-reinforcement interaction by means of large scale laboratory tests. University of Oxford, Oxford

Peerun MI, Ong DEL, Choo CS (2019) Interpretation of geomaterial behavior during shearing aided by PIV technology. J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002834

Peerun MI, Ong DEL, Choo CS, Cheng WC (2020) Effect of interparticle behavior on the development of soil arching in soil-structure interaction. Tunn Undergr Space Technol 106:103610. https://doi.org/10.1016/j.tust.2020.103610

Potyondy JG (1961) Skin friction between various soils and construction materials. Géotechnique 11:339–353. https://doi.org/10.1680/geot.1961.11.4.339

Powers MC (1953) A new roundness scale for sedimentary particles. J Sediment Res 23:117–119. https://doi.org/10.1306/D4269567-2B26-11D7-8648000102C1865D

Read HE, Hegemier GA (1984) Strain softening of rock, soil and concrete—a review article. Mech Mater 3:271–294. https://doi.org/10.1016/0167-6636(84)90028-0

Scherge M, Gorb SN, Gorb S (2001) Biological micro-and nanotribology. Springer Science & Business Media, NY

Sharma H, Mishra S, Rao KS, Gupta NK (2018) Effect of cover depth on deformation in tunnel lining when subjected to impact load. In: ISRM international symposium–10th asian rock mechanics symposium, ARMS 2018. Singapore

Sia AHI, Dixon N (2007) Distribution and variability of interface shear strength and derived parameters. Geotext Geomembr 25:139–154. https://doi.org/10.1016/j.geotexmem.2006.12.003

Singh S, Singh G, Prakash C, Ramakrishna S (2020) Current status and future directions of fused filament fabrication. J Manuf Process 55:288–306. https://doi.org/10.1016/j.jmapro.2020.04.049

Smith A, Heather-Smith HJ, Dixon N, Flint JA, Pennie D (2020) Acoustic emission generated by granular soil-steel structure interaction. Geotech Lett 10:119–127. https://doi.org/10.1680/jgele.19.00065

Stark TD, Williamson TA, Eid HT (1996) HDPE geomembrane/geotextile interface shear strength. J Geotech Eng 122:197–203

Thakur V, Nordal S, Viggiani G, Charrier P (2018) Shear bands in undrained plane strain compression of Norwegian quick clays. Can Geotech J 55:45–56. https://doi.org/10.1139/cgj-2016-0443

Thenevin I, Blanco-martín L, Hadj-hassen F, Schleifer J, Lubosik Z, Wrana A (2017) Laboratory pull-out tests on fully grouted rock bolts and cable bolts: results and lessons learned. J Rock Mech Geotech Eng 9:843–855. https://doi.org/10.1016/j.jrmge.2017.04.005

Uesugi M, Kishida H (1986) Influential factors of friction between steel and dry sands. Soils Found 26:33–46. https://doi.org/10.3208/sandf1972.26.2_33

Uesugi M, Kishida H (1986) Frictional resistance at yield between dry sand and mild steel. Soils Found 26:139–149. https://doi.org/10.3208/sandf1972.26.4_139

Vangla P, Gali ML (2014) Image-segmentation technique to analyze deformation profiles in different direct shear tests. Geotech Test J. https://doi.org/10.1520/GTJ20130138

Vangla P, Gali ML (2016) Shear behavior of sand-smooth geomembrane interfaces through micro-topographical analysis. Geotext Geomembr 44:592–603. https://doi.org/10.1016/j.geotexmem.2016.04.001

Vangla P, Gali ML (2016) Effect of particle size of sand and surface asperities of reinforcement on their interface shear behaviour. Geotext Geomembr 44:254–268. https://doi.org/10.1016/j.geotexmem.2015.11.002

Vangla P, Latha GM (2015) Influence of particle size on the friction and interfacial shear strength of sands of similar morphology. Int J Geosynth Ground Eng. https://doi.org/10.1007/s40891-014-0008-9

Vangla P, Roy N, Gali ML (2018) Image based shape characterization of granular materials and its effect on kinematics of particle motion. Granul Matter. https://doi.org/10.1007/s10035-017-0776-8

Vangla P, Wala BA, Gayathri VL, Frost JD (2022) Snakeskin-inspired patterns for frictional anisotropic behaviour of split set rock bolts. Géotech Lett 12:95–100. https://doi.org/10.1680/jgele.21.00076

Wang P, Sang Y, Shao L, Guo X (2019) Measurement of the deformation of sand in a plane strain compression experiment using incremental digital image correlation. Acta Geotech 14:547–557. https://doi.org/10.1007/s11440-018-0676-z

Wang R, Ong DEL, Peerun MI, Jeng DS (2022) Influence of surface roughness and particle characteristics on soil-structure interactions: a state-of-the-art review. Geosciences (Switzerland) 12:1–36. https://doi.org/10.3390/geosciences12040145

Yan X, Gu P (1996) A review of rapid prototyping technologies and systems. CAD Comput Aided Des 28:307–318. https://doi.org/10.1016/0010-4485(95)00035-6

Yu M, Reddyhoff T, Dini D, Holmes A, O’Sullivan C (2022) Acoustic emission enabled particle size estimation via low stress-varied axial interface shearing. IEEE Trans Instrum Meas 71:1–10. https://doi.org/10.1109/TIM.2022.3156175

Zettler TE, Frost JD, DeJong JT (2000) Shear-induced changes in smooth HDPE geomembrane surface topography. Geosynth Int 7:243–267. https://doi.org/10.1680/gein.7.0174

Acknowledgements

This work is supported by the Science and Engineering Research Board (SERB), India (Project code: SRG/2019/000561). The authors also acknowledge Lt Col Shishir Makwana and Mr Sudeep Nigam, Master of Technology students at the Indian Institute of Technology Delhi, for their assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gayathri, V.L., Vangla, P. & Dey, S. A versatile apparatus for assessing the shear behaviour of geotechnical interfaces coupled with imaging and acoustic capabilities. Acta Geotech. (2024). https://doi.org/10.1007/s11440-023-02220-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11440-023-02220-9